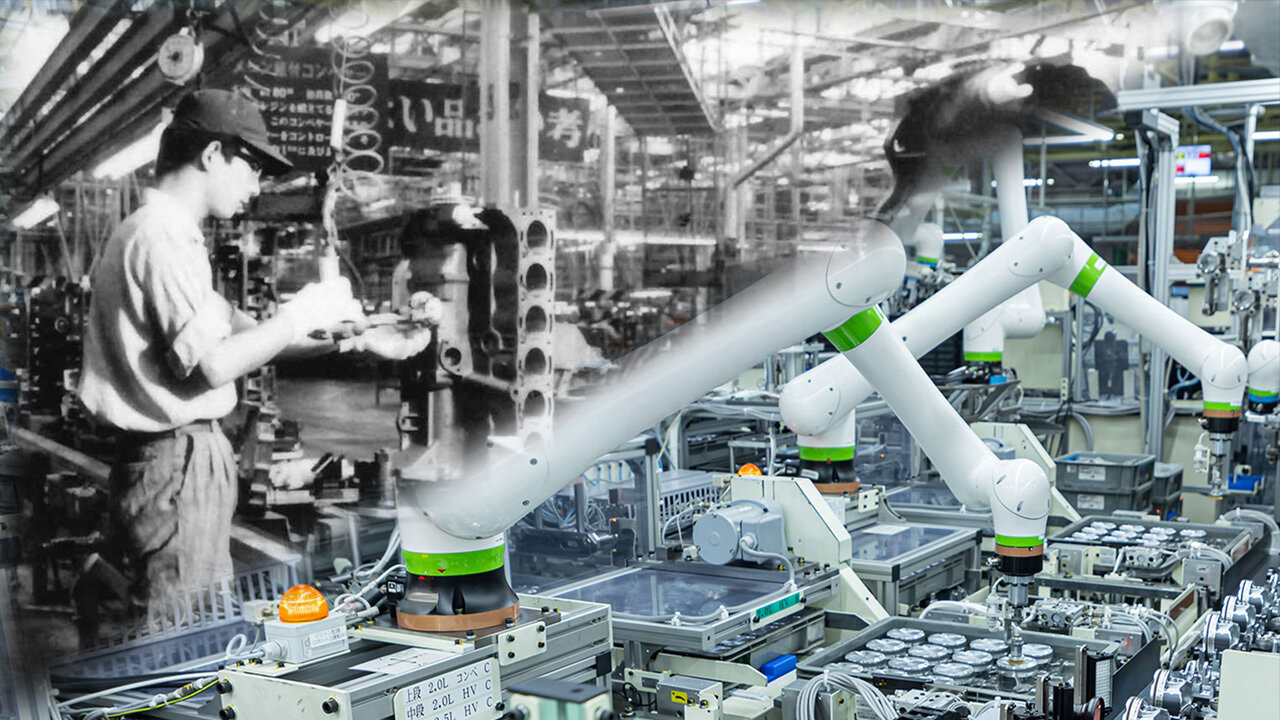

Toyota's Plants: Inheritance & Evolution is a series introducing the history and future vision of individual production facilities. This article shines the spotlight on the company's first engine plant.

Where veteran workers share their skills

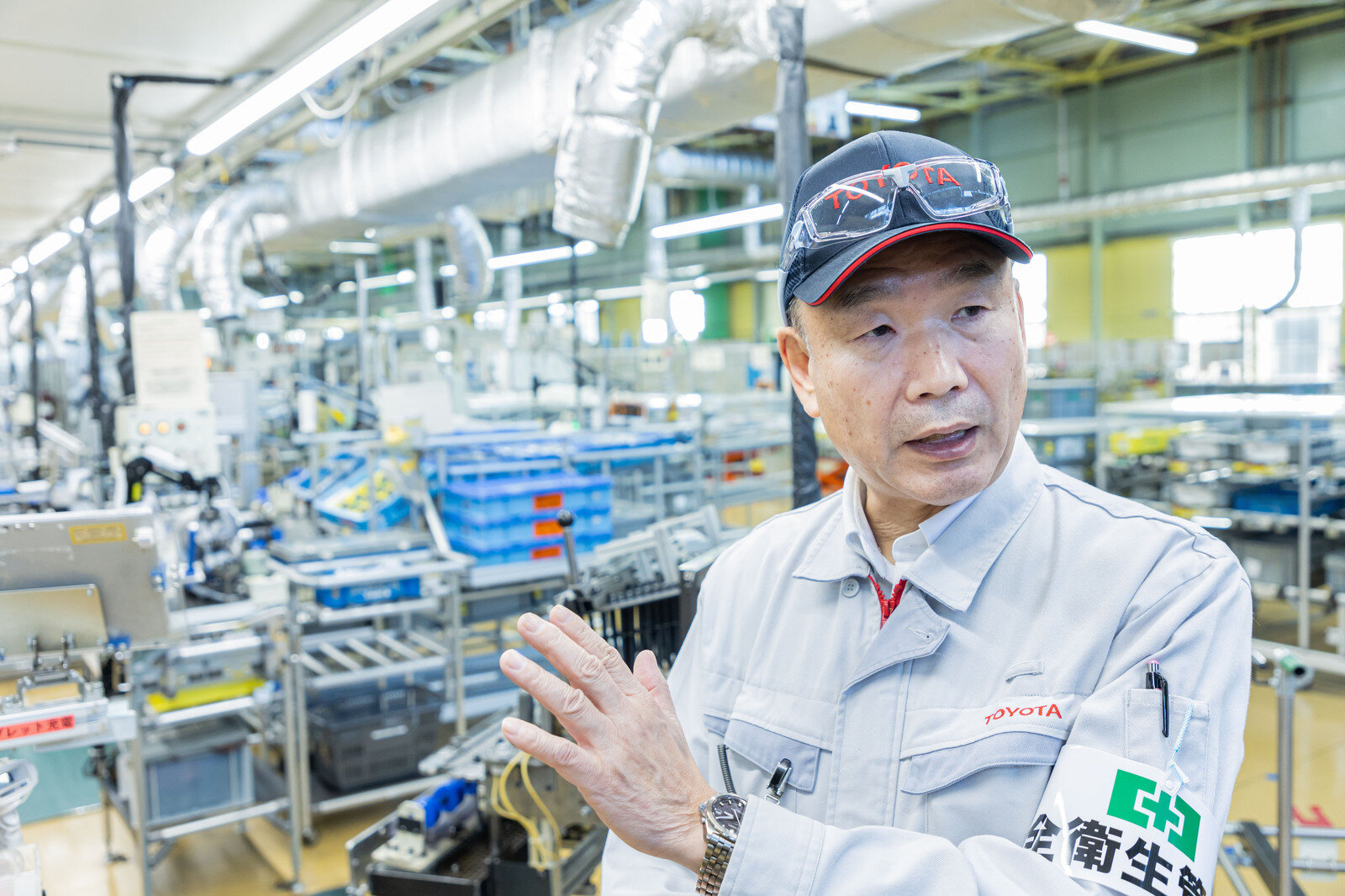

Next, we head to the Super Skill (SS) Line, created as a place where employees rehired after reaching retirement age can thrive. The line was launched in 2013, in anticipation of an increase in older plant workers over the coming years.

The proposal for the SS Line was written by none other than Plant General Manager Saito, then a section manager. He spoke to us about that process.

Plant General Manager Saito

We created a set of indicators for evaluating how well older workers could do their jobs. It contained many categories, from picking up small bolts to multitasking and carrying heavy objects, and we assessed each task individually.

From there, we improved the areas with lower scores, then built a line that older staff could easily operate. It was a joint effort between our veteran and highly skilled technicians, and us kaizen professionals.

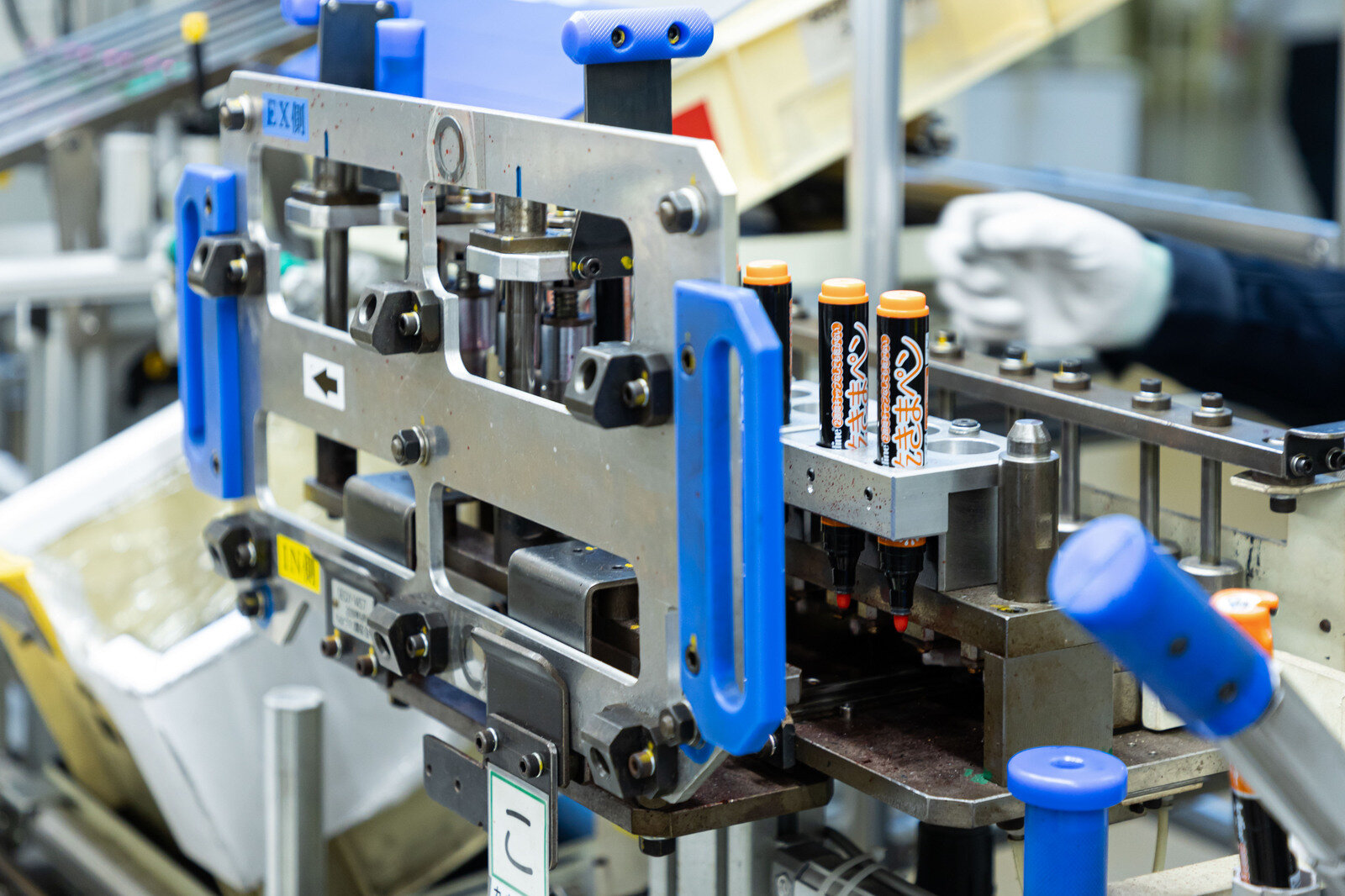

The SS Line is all about simplicity and working by hand. It makes ample use of karakuri, devices and mechanisms that boost efficiency by utilizing principles such as gravity or levers instead of electricity. The jigs and karakuri created here are deployed directly onto the plant’s TNGA line or adapted for automated machinery.

Plant General Manager Saito emphasizes the importance of the SS Line. “Those who assemble parts manually on this line go on to create automated machines that largely follow the order of work done by hand. After training here, all that’s left is to learn how to operate the machinery, and then you understand everything that is happening within the equipment.”

In fact, besides giving rehired workers a place to thrive, the SS Line has also taken on another mission: to serve as a skills transfer line for developing expert technicians.

Currently, six staff from Toyota Loops, a group company that employs people with disabilities, are also handling some of the tasks alongside veteran team members.

“While working towards simple automation, this section also contributes to diversity, continuing to make things better,” emphasizes Project General Manager Masayuki Fukai. “The SS Line may grow, but it will never become obsolete.”

Inheritance beyond the production line

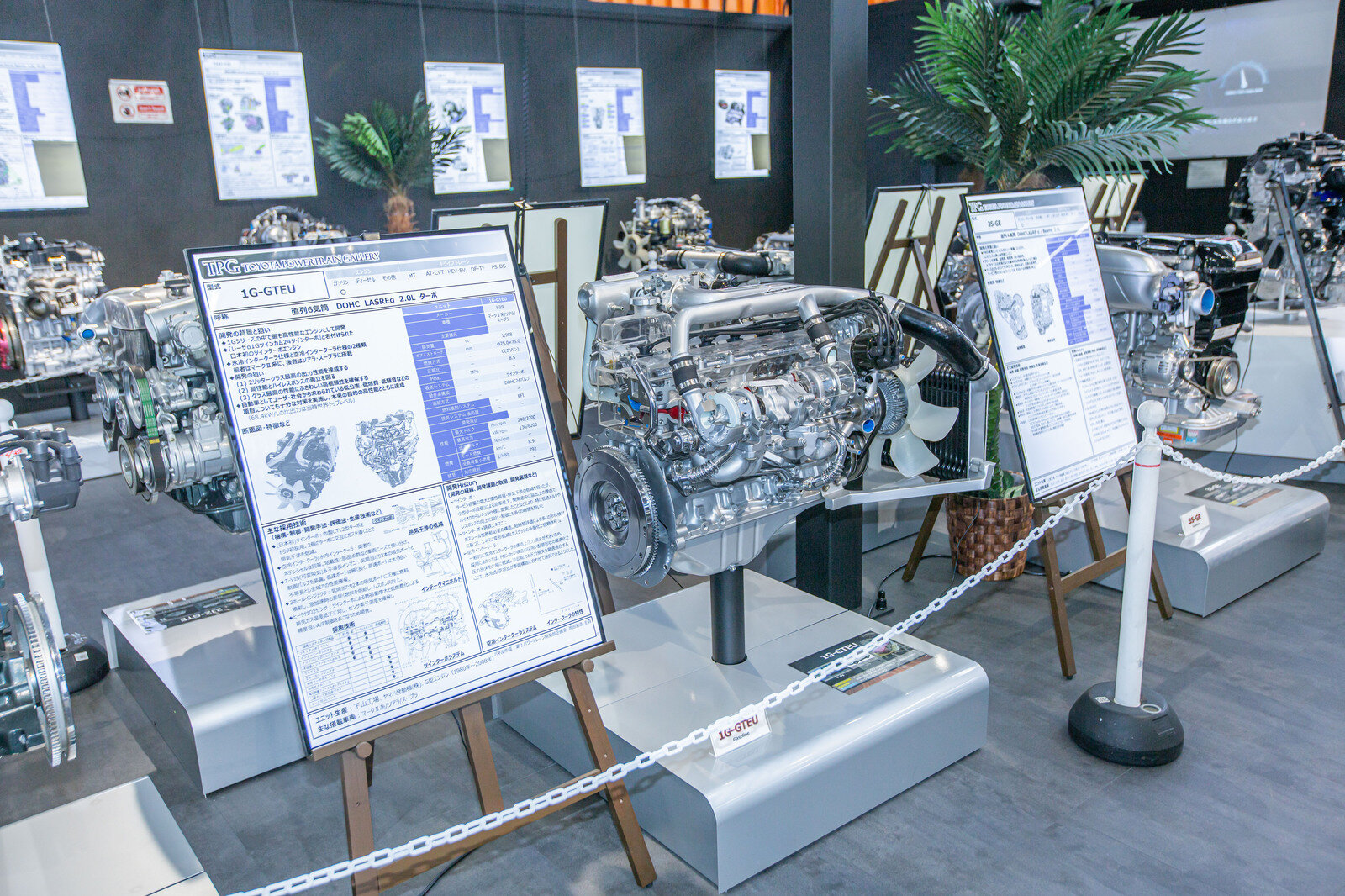

The Toyota Powertrain Gallery, opened in August 2024, showcases past generations of Toyota engines and transmissions, offering a well-organized resource for anyone keen to learn about the history of powertrains.

This project was initiated by a group of volunteers, chiefly from the Powertrain Function Development Division, who worried that precious engines and transmissions stashed away in Toyota’s various unit plants and the Haruhi Parts Center (Aichi Prefecture) might be lost if not collected in one place. They were joined by members from the Kamigo and Kinuura plants. Since Kamigo possessed storage space—and had the distinction of being Japan’s first dedicated engine plant—it was chosen to host the gallery.

The oldest item on display is a replica of the original Type A engine built in 1935. On the transmission side, there is a two-speed automatic transmission used in the first-generation Crown.

Including those kept in storage, the gallery currently houses and displays some 250 powertrains gathered from Kamigo, Shimoyama, Kinuura, the Honsha Plant, Miyoshi, and Myochi. Outside visitors can view the gallery by making an appointment through a Toyota employee, with the facility regularly welcoming local residents and students from nearby schools.

Among those tasked with taking care of the Powertrain Gallery is Chief Expert Mamoru Iwaoka of the Kamigo Plant/Shimoyama Plant Management Division’s Plant Strategy Department. He remembers being moved by the sight of a senior employee standing before an exhibit with a junior colleague, recounting stories of its development.

Chief Expert Iwaoka

Although they might want to share their memories, they don’t have the original engines or transmissions on hand. I think having the actual objects in front of you brings all these stories out.

Within a few more years, those senior members will leave the company. I realized they were making good use of this place as a way to pass on their knowledge.

The Powertrain Gallery is also considering organizing the technical staff who were involved in development to give presentations in front of the exhibits, contributing to the process of inheritance.

At the same time, the team is still collecting the powertrains scattered around plants in various locations. This fall, they plan to display the Type M engine, the Kamigo Plant’s first creation.

Three Pillars of Workplace Operations

So far, we have looked into the Kamigo Plant’s history and efforts to pass on technical skills. Now we would also like to touch on a slightly different kind of inheritance: the workplace operational changes that began at Kamigo.

After 2000, Toyota added new engine plants against a backdrop of expanding production overseas. Together with Shimoyama and Tahara, Kamigo supported these efforts as a mother plant.

However, since each of the three plants offered its own approaches to various initiatives, including TPS and quality improvement efforts, overseas genba staff were often unsure of what to prioritize. Even in Japan, these activities were repeatedly revised to keep up with increasing scale, forcing the genba to course-correct each time.

Then in 2007, the key points for the monozukuri genba were organized into the “Three Pillars of Workplace Operations,” comprising people, products, and facilities.

・People: Rigorous implementation and revision of standardized tasks

To ensure safety and prevent quality issues, work should strictly adhere to standard procedures, with manuals updated to reflect improvements*.

*Work procedure manuals are documents containing instructions for individual processes, explaining how to carry tasks out correctly. These are revised whenever improvements are made.

・Products: Process point management

When machining parts, aspects such as the point of blade contact or tightening torque should be controlled to avoid defects.

・Facilities: Ownership of maintenance

Specify points in the genba that should be inspected to maintain equipment, preventing breakdowns and stoppages.

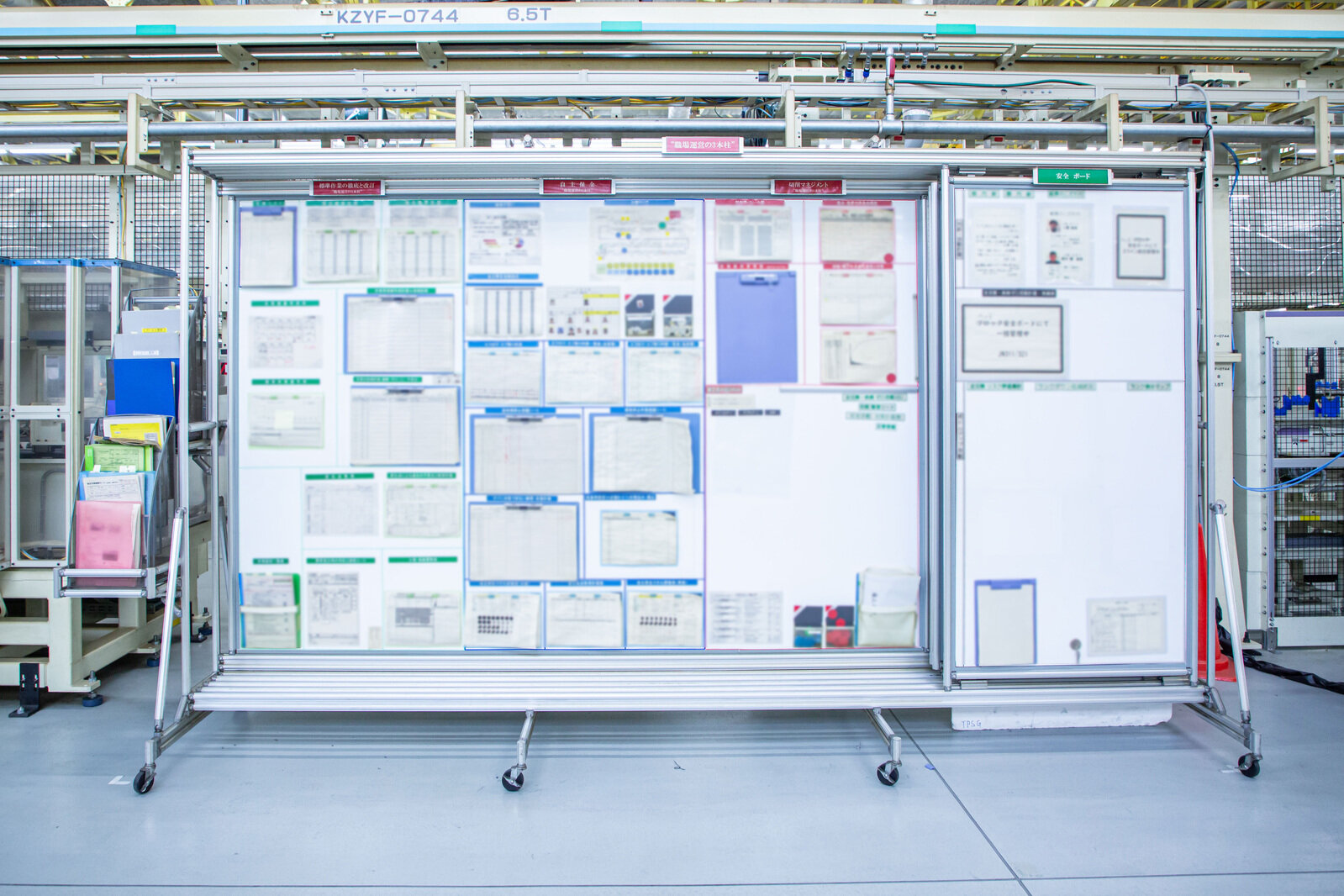

These Three Pillars clarify the essential requirements for running a workplace. They have been shared with the Shimoyama and Tahara plants and replicated globally. In Japan, group leader management boards are used to share each group’s strengths and weaknesses in relation to the Three Pillars, helping to create dynamic workplaces that operate smoothly.

“If the group leader overseeing activities understands what needs to be done, they can help their members to grow through the process. With the Three Pillars, what needs to be done is clearly laid out, making the leader’s job easier,” says Hiroshi Ito, a group manager at the Kamigo Plant/Shimoyama Plant Management Division's Skill Development Department.

Part two of this article, focusing on evolution, will look at how the Kamigo Plant has begun to digitalize these group leader management boards. “Even as digitalization proceeds, I believe we must continue to teach the ideas and objectives behind the Three Pillars,” says Group Manager Ito, looking to the future.

These sentiments were echoed by Kiyoshi Tsujioka, manager of Engine Manufacturing Section No.11 (Kamigo Plant Engine Manufacturing Div.1). “I want our junior colleagues to understand that dedication to the Three Pillars will always continue to raise KPI and deliver results.”

What lies behind the plant’s evolution

At present, the Kamigo Plant is pushing to digitalize and automate, with efforts led by younger employees. And yet, regardless of the progress in that project, certain things must never change.

The Kamigo Plant’s evolution is underpinned by the presence of senior personnel who take up the ideas of their predecessors, give them shape, and pass them on to the next generation.