Our ongoing series looking at the master artisans supporting the automotive industry. For the 21st installment, we spoke with a sheet metal master whose outstanding skills bring car body designs to life with unmatched precision.

Handwork still plays an important role in today’s car manufacturing, even as technology like AI and 3D printing offer more advanced methods. This series features the craftsmanship of Japanese monozukuri (making things) through interviews with Toyota’s carmaking masters.

In this two-part feature, we showcase the Body Manufacturing Engineering Division’s Takahiro Maeda, whose exceptional sheet metal skills make the correction process for stamping dies more efficient, while also helping to craft vehicle bodies with outstanding precision.

#21 Takahiro Maeda, the sheet metal master who turns designers’ dreams into reality

Stamping Equipment Certification Section, Body Manufacturing Engineering Division, Toyota Motor Corporation

Precision challenges unique to composite parts

Where Takahiro Maeda’s expertise truly comes to the fore is in the high-precision adjustment of body panel parts such as doors and engine hoods, known as “shell” components. These parts are made by combining two steel sheets, the inner and outer panels.

Maeda

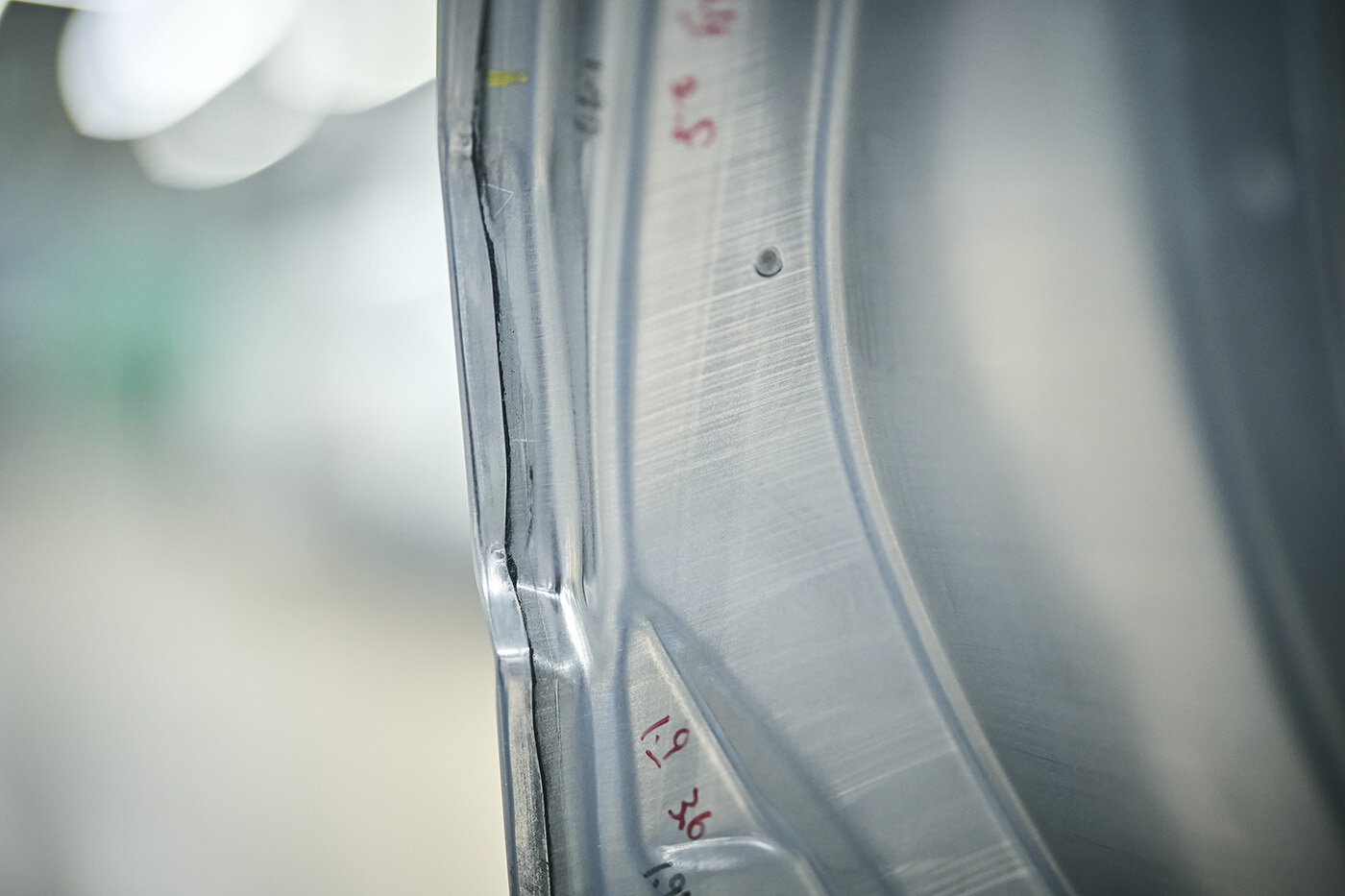

Generally, a vehicle body consists of single panels, but doors and other shell components have outer and inner pieces hemmed together. This hemming process inevitably causes deviations from the design values.

The hemming process involves wrapping the outside edges of the outer panel around the inner one to form a single part, and the different thicknesses of these two sheets make plastic deformation unavoidable. Inner panels are thicker to provide greater safety in collisions, and this difference impacts precision during hemming.

Maeda’s role is to produce panels that precisely match the design values by using his sheet metal skills to correct any deviations caused in the hemming process. The corrected panels are measured to provide data on how much revision was required, which is then used to adjust the stamping dies. This process, from fixing the surface to generating data for improving dies, is known as inner hem rework analysis.

Maeda

Essentially, our role is to handwork the metal such that, when the car is finally assembled, the body fits together exactly as designed.

Craftsmanship down to three-tenths of a millimeter

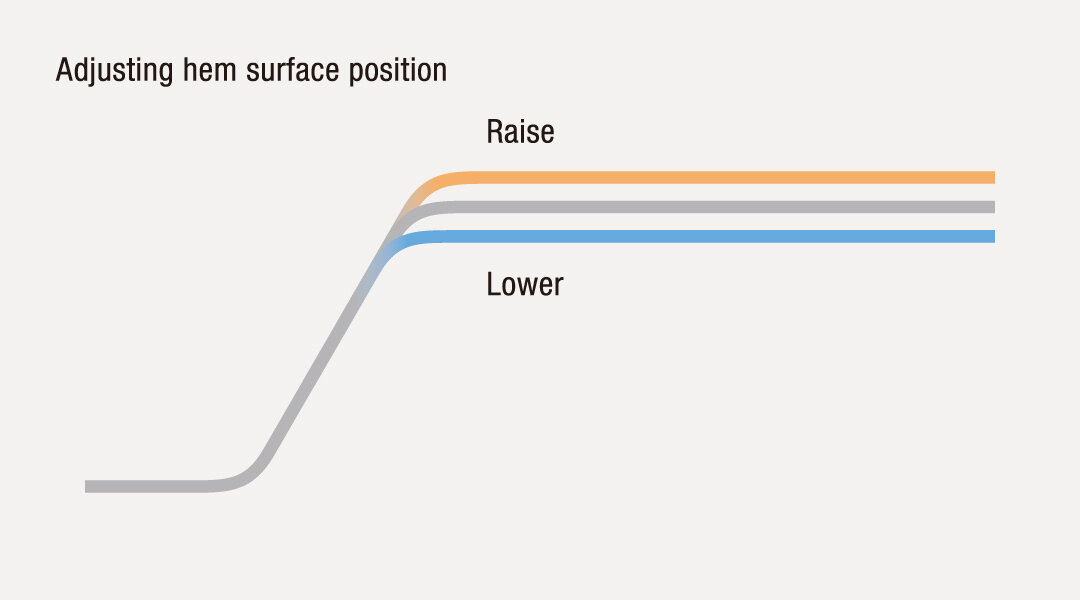

When Toyota Times visited, Maeda showed us how he corrects an inner hem. Using the section where the rear door touches the fender as an example, he demonstrated how to both raise and lower the hem surface (shifting it further from or closer to the vehicle, respectively).

Maeda

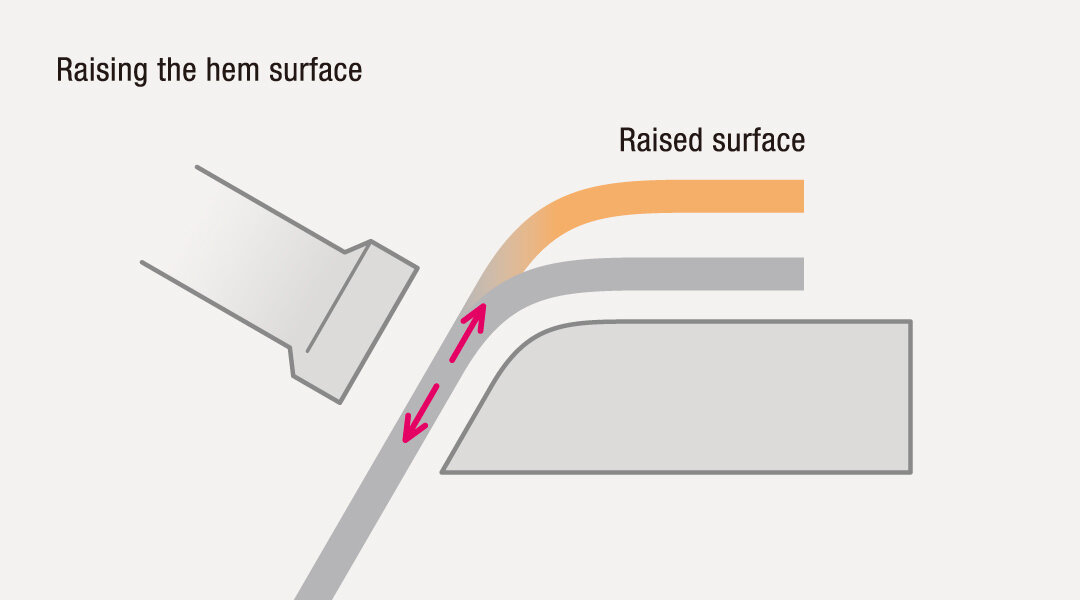

When raising the hem, if you hit the surface you want to lift directly, its edge and base will deform unevenly. I raise the hem’s surface by hammering it from the side, elongating the excess metal.

The key here is adjusting the gap between the metal and the dolly (the backing block for hammering). Maeda intentionally leaves a gap that allows him to control how the sheet lengthens.

Maeda

When hammering the side of the hem surface, I leave a little space. Although this is like striking without backing, the idea is to let the excess metal fill up this space as it elongates.

By contrast, to lower the hem Maeda hits the surface directly, with the dolly set firmly against the back of the metal.

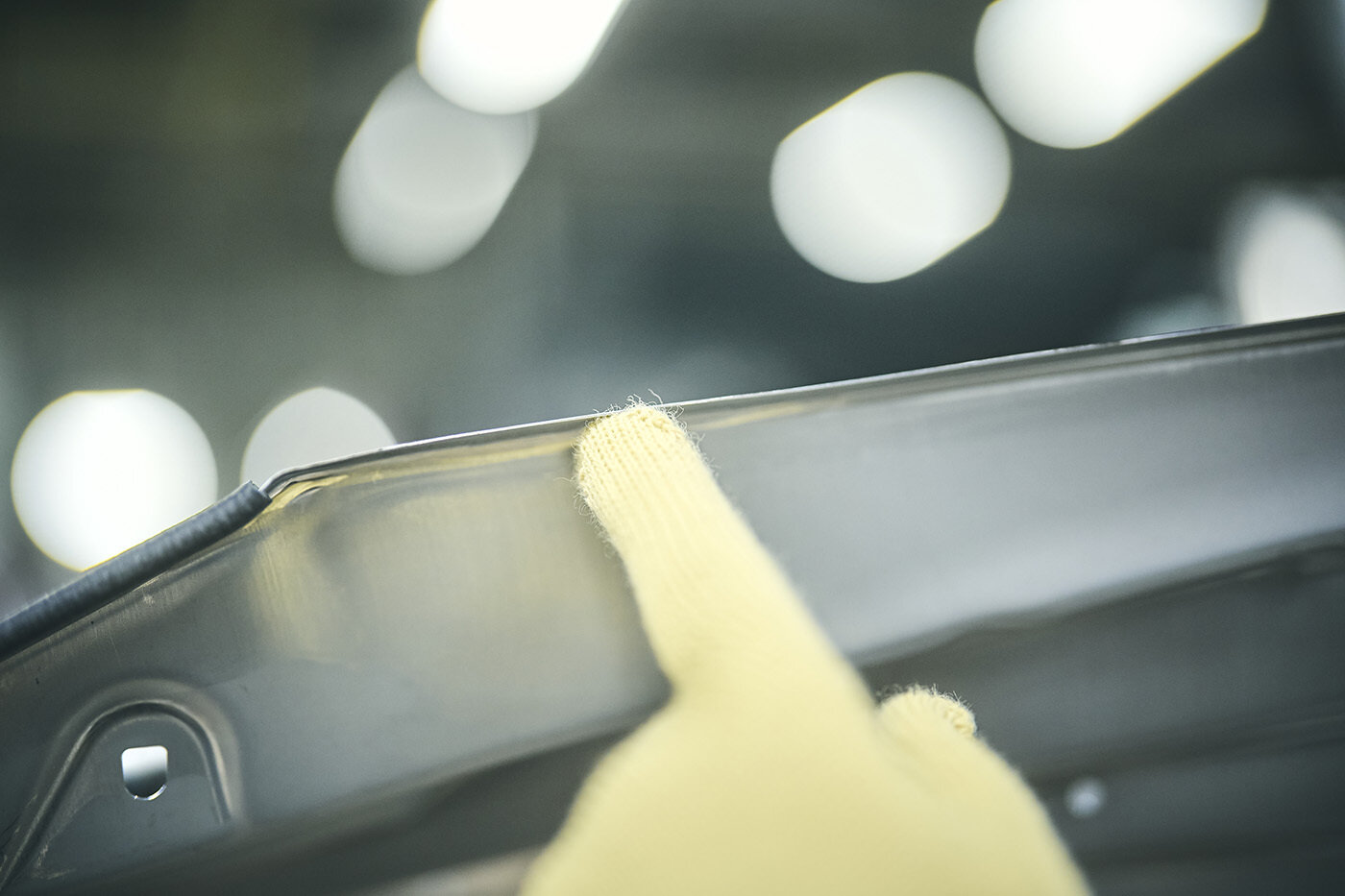

Maeda’s work is astonishingly precise. With two or three blows of the hammer, he adjusts the surface by about 0.3 mm. As explained earlier, the ultimate goal is to eliminate any height differences and ensure even gaps between body panels once the vehicle is finished.

Maeda

Just now, I raised the hem by about 0.3 mm. You can see that this section is higher than the areas I haven’t touched.

As he works the hammer, Maeda’s eyes pick up subtle changes too small to notice as an onlooker.

Maeda

While working, I’m not watching the hammer, but checking the changes in the surface I am correcting. In fact, I don’t look at the hammer at all.

These skills are backed by expertise rooted in Maeda’s extensive experience as a sheet metal master.

Maeda

I can picture in my head exactly how much the surface will deform if I put this much force into the hammer. The material’s thickness and geometry affect how the hammer recoils, so I use that sensation to adjust my strength.

A master line for all Toyota models

Maeda’s team uses contactless three-dimensional measuring instruments to accurately capture the surface and profile data of body panels.

Maeda

Surface data is a measurement of height differences between door panels and body surfaces. Profile data measures whether gaps between door panels and the body are uniform.

These measuring instruments clarify the areas that Maeda needs to correct, and his target values. When it comes to the actual fine-tuning, however, the technician draws on his skills and senses. Measuring equipment can provide accurate numbers, but only Maeda’s hands and instincts can turn those numbers into reality.

The precision adjustments that Maeda performs day-to-day do not only benefit the Motomachi Plant. His skills support Toyota’s carmaking on a much larger scale.

The Body Manufacturing Engineering Division’s Stamping Equipment Certification Section, to which Maeda belongs, has a special standing among Toyota’s production facilities. As the “master line,” this plant serves as a reference that sets quality standards for Toyota vehicles produced all around the world.

Maeda

All of the shell component rework analysis for cars produced by Toyota is handled by our team. In other words, we provide the die data to ensure correct dimensions for all new models being prepared for production, including those made at our overseas plants.

The rework analysis performed by Maeda and his colleagues creates high-precision stamping dies that are shared with production plants in Japan and beyond, ensuring that body parts of the same quality can be manufactured around the globe. To put it another way, Maeda’s team plays a part in maintaining the quality of Toyota vehicles found on the world’s roads.

Engineers involved in body design call Maeda the “Hammer Wizard,” given his ability to bring their desired forms to life with nothing more than a hammer. Such mastery is particularly sought after when dealing with design changes.

Various design changes crop up during the development process. For example, if water is found seeping into the vehicle during leak tests, the geometry of roof joints will need to be modified. If crash tests reveal issues with the body’s strength, inner panels must be reinforced for greater rigidity.

Normally, for each such change a new stamping die would need to be fabricated and then used to produce an actual part to check its effectiveness. Unfortunately, doing so adds significant time and cost to development.

Instead, by having Maeda create the updated body parts from sheet metal, the effects of design changes can be rapidly verified and confirmed. His mastery of the craft is able to shorten development times while also improving quality.

The craftsmanship underpinning ever-better carmaking

Maeda is currently also putting his energies into training junior colleagues. He is nurturing the next generation of craftspeople by helping them obtain national skills qualifications.

With Maeda’s guidance, multiple technicians have gained their Grade 1 certification, with some even aiming for the same Special Grade that he possesses.

Maeda

Once you have earned Grade 1 in both bending and hammering skills, you are eligible to take the test for the Special Grade, the highest level. Ultimately, I hope to train all of our team members to reach the Special Grade.

Having been given the opportunity to compete in WorldSkills, I consider it my mission to pass on these skills to younger colleagues. As well as continuing to advance my own skills, I want to contribute to Toyota’s ever-better carmaking by sharing them with my pupils.

As Maeda notes, such craftsmanship plays a crucial role in making ever-better cars, the vision laid out by Chairman Akio Toyoda during his presidency.

Maeda

In the past, we often added design restrictions to prioritize ease of manufacturing. Now, however, the mindset has shifted toward figuring out how we can turn the designers’ dreams into reality.

This change has greatly increased the difficulty of stamping components. For example, more complex and captivating designs, such as the latest Crown series, are more prone to plastic deformation after stamping and deviations during assembly.

Bringing the designer’s unfettered creativity to life, while also ensuring quality in mass production—being able to fulfill these seemingly contradictory demands is the magic of masters such as Maeda.

Maeda is working to ensure that the next generation can benefit from his WorldSkills expertise, and to share his passion for ever-better carmaking with the industry’s future. The Hammer Wizard nickname is more than just a sign of respect and admiration for his abilities; it reveals a deeply rooted belief in the value that can only be created by human hands and instincts.