Can one little device upend accepted wisdom in rehabilitation care?! Welgain is already being used in clinical practice. So, what exactly is it?

Dr. Otaka, Fujita Health University Hospital

Human movement is both visible and hard to visualize. Even if you think someone’s walk is well balanced, without quantification, that’s hard to analyze.

One day in December, Kobayashi from Toyota came to me with an idea, saying, “Here’s a Christmas present!” I thought he was onto something.

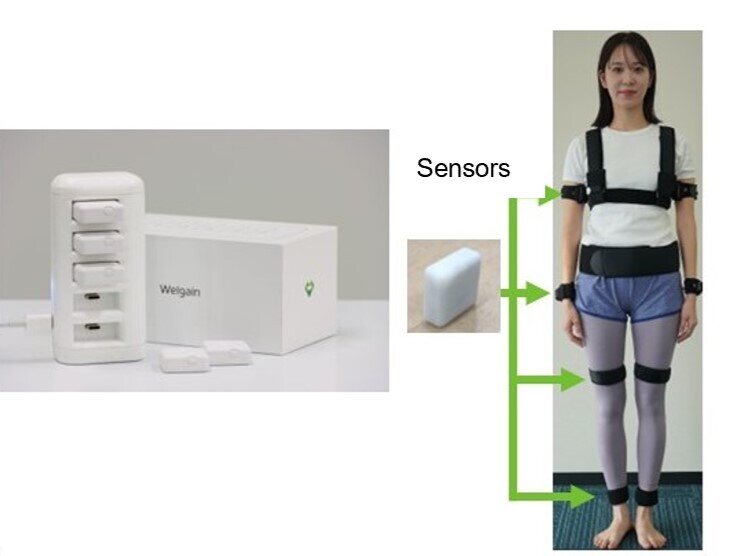

In 2019, Toyota’s team began joint development with Fujita Health University Hospital. However, their device had to overcome three major challenges:

1. Be simple to fit and easy to use for quick data measurement.

2. Be able to maintain a stable connection in any location.

3. Be highly reliable.

Dr. Otaka, Fujita Health University Hospital

Even if you create a good product, in a bustling clinical environment it won’t get used unless it is simple. The key is usability.

Also important is converting data into usable information. In every aspect, we focused on usability in a clinical setting.

The biggest technical hurdle was the Bluetooth connectivity. In a large hospital filled with all manner of wireless signals, ordinary devices drop out at a distance of five to ten meters.

What’s more, since human bodies absorb radio waves, connections are even harder to maintain when multiple people are moving and getting in the way, such as when a patient and physical therapist work together. The team continued to pursue improvements.

Group Manager Kobayashi, New Business Planning Division

Welgain can quantify all kinds of human motions, including walking and standing, as well as more subtle movements.

Because it provides sound alerts for poor posture, the system has the potential to benefit people in various situations beyond rehabilitation, such as helping plant employees avoid work-related back pain, or improving an athlete’s form to prevent sports injuries.

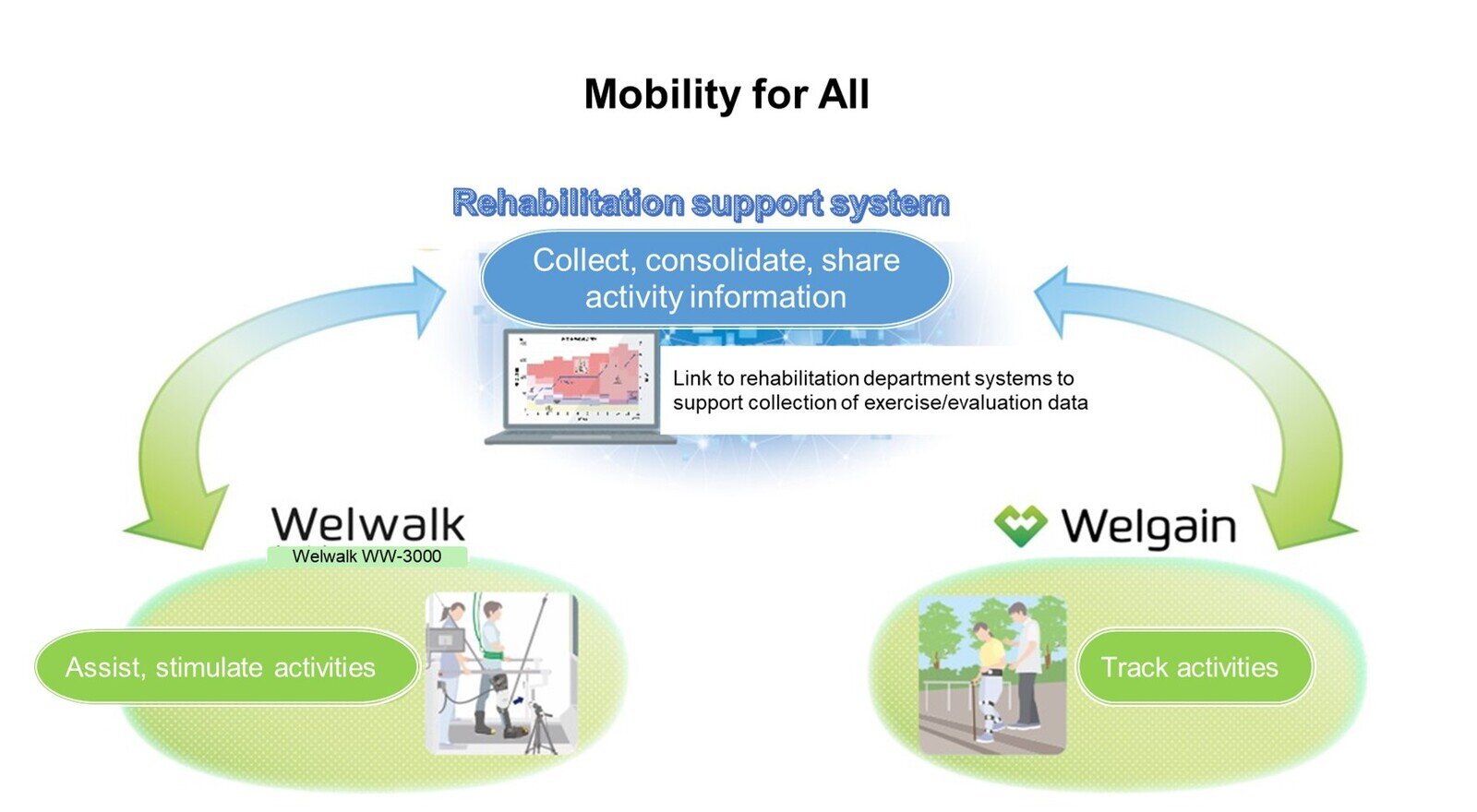

Toyota and Fujita Health University Hospital also jointly researched a rehabilitation assistance system that can collect, consolidate, and share data from exercises and evaluations.

Dr. Otaka, Fujita Health University Hospital

Astonishingly, detailed data, such as the minutes spent on walking exercises, is normally not kept for rehabilitation procedures.

At this hospital, we had devised codes for adding this to our electronic medical records, but Toyota was able to adapt the system for broader application.

The ultimate goal is to consolidate all the granular data. Doing so will provide a fuller picture from past to present and enable sharing between teams.

“Through scientific analysis, we will be able to see what happens when you do something for a given length of time—in pharmacological terms, the ‘dose-response curve,’” says Dr. Otaka.

Group Manager Kobayashi, New Business Planning Division

Creating a good system means creating extra capacity for the doctors. We ourselves cannot provide medical treatment. But can we do something for the medical staff and patients? We want to help those in need.

“It seems the folks at Toyota aren’t satisfied without a complete overhaul,” remarks Dr. Otaka with a laugh. “As a doctor, I feel very lucky that they are reconsidering rehabilitation from the ground up.”

Together with colleague Haruki Inoue, a smiling Kobayashi told us, “When we explain it at the hospital, the response is, ‘What! It’s that simple? You can do all that?’ And when we do demonstrations, they’re amazed.”

Can you see this?

In developing Welgain to measure high-precision data, the team received indispensable support from another company: Mie Electronics, a 55-year-old maker of wide-ranging products, from liquid crystals and electronic devices to medical care equipment.

“Mie Electronics is the company you turn to when you’re really stuck,” says Kobayashi.

Even so, all kinds of challenges surfaced during development.

The biggest hurdle was the need to accommodate components of various heights on the circuit board to send a stable signal over long distances.

“Can you see this?” Koji Nihonsugi of Mie Electronics adjusted his glasses as he provided an explanation.

Components of different sizes require different temperatures when soldering. The process involved adjustments of as little as 30 microns, about the width of two hair strands. The Mie staff assured us that such precision was rarely required.

“That’s greater precision than a smartphone,” says Shuhei Takazakura. There was one thing that helped him to overcome this daunting task.

“When my grandmother was ill, I wished for a way to preserve people’s dignity and, as much as possible, enrich their time. I wanted technology to bring us closer together and create moments like chatting happily as a family, moments that would remain with us into our children’s future. That’s what made the development so enjoyable.”

The smiling faces of everyone we interviewed left a lasting impression.

Rehabilitation is about “restoring dignity and facilitating activities that help the individual regain their way of life.”

These are profound words—which makes Toyota’s efforts all the more meaningful.