Engine sounds enchant car enthusiasts. But what makes for a satisfying tone? In part six, we seek to uncover Toyota's sound design goals.

What is a “good” sound?

Through the series so far, we have learned that crafting a pleasing engine sound means emphasizing certain tones and eliminating others. But what exactly characterizes the “good sound” that Toyota is pursuing?

“Something that enables intuitive driving and a dialogue with the vehicle—these are our basic principles for sound development across the brand,” says Yusuke Nakayama, an assistant manager at the Lexus Vehicle Performance Development Division’s Vehicle Performance Development Department No.1, who was involved in crafting the sound of the Lexus LC.

Indeed, when we asked Nakayama to explain the GR Yaris’s Active Sound Control (ASC) in part five, he spoke of “designing sounds that allow you to engage in dialogue with the car.”

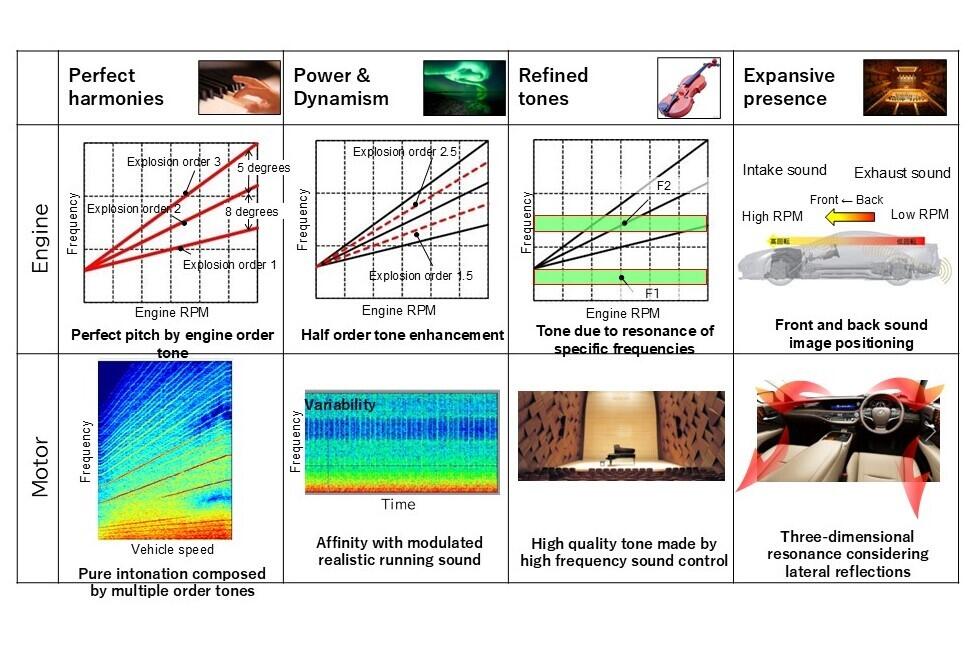

Based on this idea, Lexus has built on the sound philosophy of its LFA model by setting out four unique sound factors to serve as a guideline: perfect harmonies, power/dynamism, refined tones, and an expansive presence.

For example, to make a sound more powerful and dynamic, it can be enhanced with half-order tones (see part five). The addition of these tones gives the sound a heart-pounding quality.

It’s a matter of adding seasoning, so to speak, to achieve a richer flavor. But how do you determine the right mixture and the right amount of half-order tones? “It’s all about the frequency bands,” explains Assistant Manager Shinichi Sano of the Vehicle Performance Development Department No.1, Lexus Vehicle Performance Development Division.

Assistant Manager Sano

For instance, if the engine is at low revs and producing low frequencies of around 250 to 300 Hz, adding half-order tones would make for a terribly noisy rumble. On the other hand, up in the high-frequency range of about 800 to 1,200 Hz gives you a nice clean howl.

We did this meticulously with the LFA. The noise is curbed as much as possible in the lower frequencies and then unleashed once you round up into the higher end.

The art of negotiation

In that case, how and when do you eliminate the sounds you don’t want people to hear? “It’s a negotiation that starts before the engine takes shape,” explains Sano.

We imagined that engineers dealt with NVH (Noise, Vibration, and Harshness) once the car had more or less come together, by adding materials to absorb sound or damp vibration. However, these considerations start from the earliest stages of development.

Since joining Toyota in 1984, Sano has worked on everything from advanced engine development to NVH-related projects, including vehicle testing, technological development, and equipment implementation. He recalls that, in the past, efforts to tackle NVH even led to organizational reforms.

Assistant Manager Sano

Our history of sound design moved from pursuing quietness to a more aggressive NV approach, through which we actively sought to create a brand sound, culminating in the LFA. By analyzing the LFA sound, we then formulated the sound factors that make up Lexus’s unique sound design philosophy (part four).

That’s not to say that a movement actively seeking good sounds didn’t exist until the LFA, but at the time Toyota consisted of three centers—one for FR cars, the second for FF, and a third for commercial vehicles and RVs—each with their own teams tackling NVH.

Our NVH work deals with various issues affected by the engine, transmission, and other components. That’s why, on the organizational side, we ensured that we have dedicated NVH negotiators in each relevant unit.

Engine, transmission, hybrid—we have roughly two negotiators for each unit. They go in and slug it out…by which I mean negotiate (laughs).

Given my background in engines, I spent six or seven years as a negotiator, engaging in heated exchanges with the engine teams while working on NVH for the ZZ and ZR, NR, AR series, among others.

Ensuring the right sounds are heard

The job of these NVH negotiators is to reach agreements with the various units, ensuring that their parts are built to achieve the target engine sound. But what about the other side in these negotiations? We asked Project Manager Takayuki Minematsu of the Powertrain Function Development Division’s Function Development Department No.3, who is part of the engine team.

Project Manager Minematsu

We adjust and reshape the balance of frequencies. Specifically, we shift the frequency bands by changing aspects such as the mass and stiffness of resonant* objects.

*Resonance: Objects have a “natural frequency” at which they vibrate more readily. Resonance occurs when an object is subjected to an external force close to its natural frequency, rapidly causing it to vibrate at a larger amplitude and produce more sound.

For example, they might come to us and say, “The engine gets too loud around 2,500—we want a sound that fits more smoothly with the RPM.” We can change the shape or material of resonating parts so that they don’t overlap with that peak at 2,500 revs, shifting the frequencies to achieve a balance that gives a smoother sound transition.

The most difficult are the relatively low frequencies. Dealing with them goes beyond the level of replacing pistons or other individual parts; instead, it requires structural revisions, such as changing the shape of the engine block or the transmission housing.

“That’s why we need to have these discussions before the engine comes together,” says Sano with a strained smile. “Bringing it up after the fact is a sure-fire way to ruffle feathers.”

And while more compact new-generation engines are a welcome development, their lighter weight makes it harder to suppress vibration. In sound design as in carmaking, progress is also accompanied by drawbacks; speaking with Toyota’s engineers, we sensed their struggle in trying to strike the right balance.

Painting on a blank canvas

To ensure that drivers can hear the intended sounds, unwanted noise needs to be eliminated. Producing good sounds and reducing the undesirable are two sides of the same coin, and as Minematsu explains, both are essential in sound design. The sentiment is echoed by Nakayama, who has worked on numerous devices for emphasizing sought-after sounds.

Assistant Manager Nakayama

When talking about Active Sound Control, I often describe it as “painting on a blank canvas,” but if you have an inferior engine without any noise cleaning, you’re painting on a stained canvas.

We want to supply a clean canvas to avoid ending up with a blemished painting. In other words, reducing noise is the most important thing we can do to actively create a good sound. Many of the issues can’t be fixed later down the track.

Basically, starting with a blank canvas gives you greater freedom of expression. Even so, that expression will be bound by the capabilities of the car in question.

Assistant Manager Nakayama

It would be strange to hear a car with an eight-cylinder engine sounding like a three-cylinder machine, and vice versa. The right sound depends on the given engine. Our basic approach is to employ tones that evoke the driving power of that particular vehicle.

To give an example of a past failure, at one point we talked about reproducing a four-cylinder sound in a vehicle with a three-cylinder engine, but the three-cylinder and four-cylinder sounds interfered with each other to produce something you couldn’t even call a sound. That just doesn’t work.

If you have a vehicle with a three-cylinder engine, you have to explore sounds that fit along that three-cylinder line.

But surely that incongruity is only noticeable to an engineer, while anyone on our level would be happy with what they heard? Nakayama and Sano both disagree: “No, you’d find it strange.”

Assistant Manager Sano

We even experimented with replicating the LFA sound in a normal car, but it was just plain comical (laughs).

A fast sound, with too much acoustic pressure, will only make a slow car seem even slower. We realized that the LFA’s tone and acoustic pressure only fit because they are backed up by its acceleration.

Pursuing perfection to the very end

Although efforts to eliminate unwanted noise begin in the early stages of carmaking, when it comes to emphasizing or adding desirable sounds, parts installed later in the process tend to have a bigger impact.

For example, the arrangement of intake and exhaust pipes can only be settled once the car’s layout has been finalized.

And yet, in part five, Assistant Manager Nakayama also spoke of the trouble he faced when trying to mount a sound generator—designed to deliver clear air intake sounds at high RPMs—into the LC’s engine bay after the layout had already been decided.

As for electronic devices like Active Sound Control, the team’s pursuit of the ideal sound carries on right to the very end.

Assistant Manager Nakayama

Because we can just rewrite software instead of modifying physical objects, we can make last-minute changes in a way you can’t with hardware. All the while apologizing to the other departments (laughs).

The more work you put in, the better it gets, so we tend to keep striving for better and better right up to the deadline.

As they shared their experiences, we were struck by the immense challenges of sound design, a constant battle that accompanies the carmaking process from start to finish.

To finish, let’s enjoy the dynamic sound of the LBX Morizo RR with Active Sound Control. That blipping, bubbling rumble is sure to set pulses racing.

To produce a more natural effect, the car’s blipping, bubbling, and various other noises emerge at random, ensuring you rarely come across the same sound twice.

These sounds are actually controlled by a very complex logic. Be sure to experience it for yourself if the opportunity arises.