Engine sounds enchant car enthusiasts. Yet even without an engine, BEVs can still use sound to delight drivers. We look at sound creation in the age of electrification.

EV-specific sound design

Toyota’s fundamental approach of “designing sounds that allow you to engage in dialogue with the car” has naturally carried over to electric vehicles, with engine-less BEVs inheriting the philosophy that guided the crafting of engine sounds.

In creating the UX300e sound, Toyota engineers also looked into the sound of Formula E cars. However, this sound too closely resembled a dentist’s drill to be useable in its original form. The team decided to cut any harsh high-frequency sounds, such as gear and airflow noises, and borrow only the genuine motor sounds (motor order sounds).

Since some of the ear-piercing high-frequencies still remained, these were cut using a low-pass filter—basically a net that blocks out high-pitched sounds, allowing only low tones to pass through.

To figure out how far to go with cutting high frequencies, Sano and his team tested the sounds in actual vehicles by people in Japan, China, and Europe, where the UX300e would be sold. They found that noises at a frequency of 3 kHz (approximately the screech of a cicada) were deemed unpleasant by all of the trial participants. Meanwhile, 95% had no problem with sounds at 2 kHz (the high-pitched sound of a water drop falling). As such, only sounds below 2 kHz were used.

In order to facilitate dialogue with the car, one key task was to design sounds that allowed the listener to perceive the vehicle’s speed.

Assistant Manager Sano

We created three sound profiles: smooth and linear up to 80 km/h, then reaching and expansive to around 120 km/h, and above that, where the car lacks power to accelerate further, a sound that lets you know “this is as high as we’re going.”

We then joined these three sound profiles smoothly to reflect the fact that motors don’t have shifting gears.

Later, when Lexus released its first dedicated BEV model, the RZ, “We stuck with the idea of layering the sound profiles across three separate regions,” explains Yusuke Nakayama, assistant manager at the Lexus Vehicle Performance Development Division’s Vehicle Performance Development Department No.1.

Assistant Manager Nakayama

By layering the profiles upon order sounds emitted by the motor, we produced sounds that evoked their source functions while also being unique to Lexus.

Within the layers, we used a special type of sound, known as “prime order sounds,” to create something more original. These prime sounds are more than just simple harmonics, if that helps.

The trouble with freedom

As Sano notes, the high degree of freedom in rendering BEV sounds actually makes development more difficult. “Everyone has very different ideas about how a BEV should sound, which makes it hard to settle on a direction. Especially for models where many people are involved, the situation is clearly going to get out of hand, so we need to ensure we have the basic sound set and ready in advance.”

On the other hand, BEVs also offer unique advantages. One particular aspect which becomes easier is noise cleaning, the preliminary step in sound design that aims to create a “blank canvas.”

Assistant Manager Sano

Since electric vehicles are so quiet, you notice noises that you wouldn't hear in an engine car, such as fans whirring or water flowing, but we can deal with these one by one. If we’re getting noise from some airflow, for example, we work to make sure air doesn't get in.

And then there’s the other noise unique to BEVs: all sorts of beeps and chirps from the many control switches (laughs).

Even then, if you know the mechanism doing the switching, it’s possible to find solutions. The good part is that most noise is produced at high frequencies, and unlike engine cars, the only real source of low-frequency sounds is the motor.

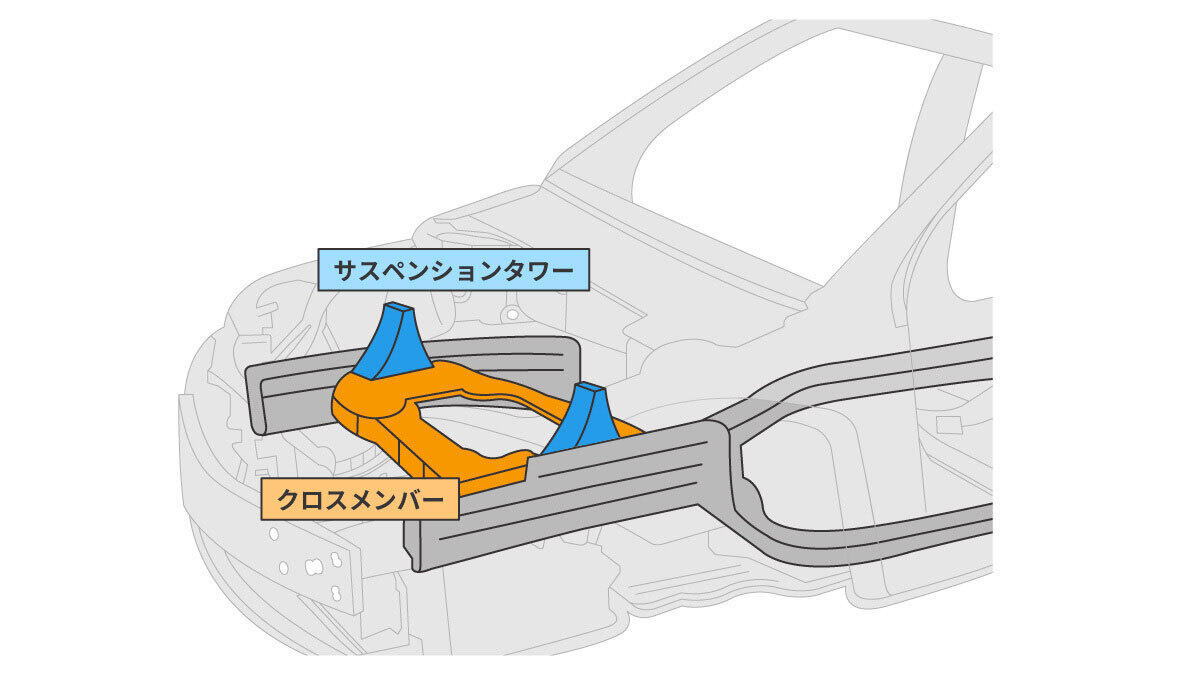

In BEVs, the motor is mounted by fitting a cross member between the two sides of the suspension tower. This prevents the suspension from collapsing in, thereby also reducing road noise. Sano explains that it is particularly effective in FF vehicles.

Another advantage of BEVs is the heavy battery that sits beneath the car.

Ultimately, the team works with actual vehicles to identify and address areas that produce noise. While Sano speaks of “possible” solutions, the work of noise cleaning is no doubt a meticulous, painstaking process.

With that, let us hear those UX300e and RZ sounds, in which Toyota’s engineers used their painstakingly and meticulously prepared white canvas to create the unique world of Lexus BEVs. Perhaps, somewhere in there, you may even feel the presence of the thunder god.