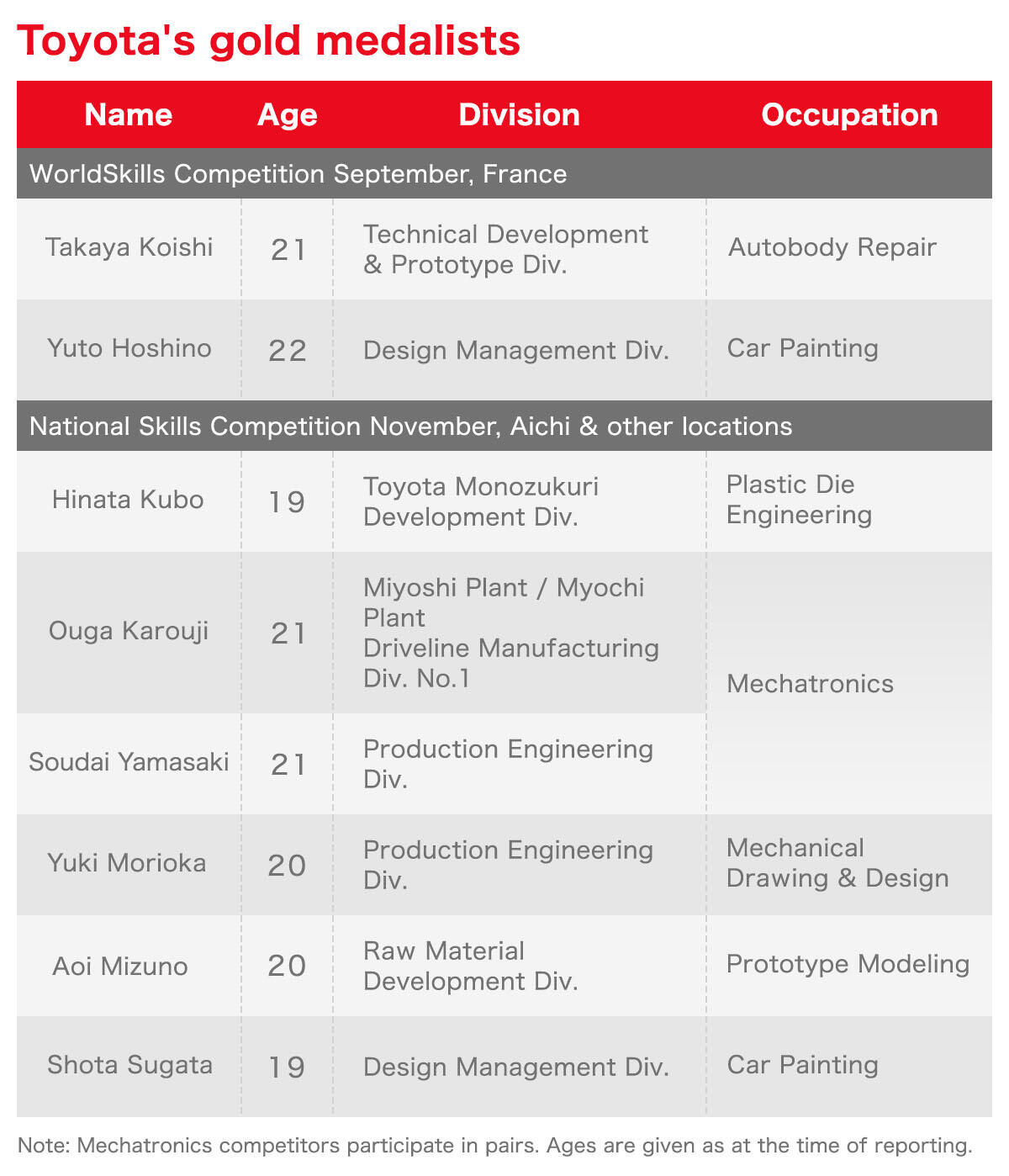

Toyota Times sat down with eight Toyota employees who won gold medals at the WorldSkills and National Skills competitions held in 2024.

As the name suggests, WorldSkills is a competition showcasing the talents of young technicians across various occupations. The international event has been running since 1950, with Japan’s national contest kicking off in 1963. (WorldSkills is held every two years, National Skills annually)

The competition covers a wide range of occupations, from industrial and construction skills such as autobody repair and plastering to dressmaking and restaurant service. In September 2024, the international WorldSkills event held in France included 59 disciplines (excluding exhibitions), while November’s National Skills Competition had 41.

Toyota fielded teams in both tournaments, with members competing in 17 different skills categories (7 at WorldSkills, 10 at National Skills) and winning eight gold medals across seven disciplines * .

*Includes Car Painting gold medals at both the international and national events.

Toyota Technical Skills Academy graduates take gold

First, let’s start with a brief explanation of the seven fields in which Toyota employees claimed top honors.

Autobody repair

Participants hammer, cut, and weld steel sheets of a given size to achieve the required shape. Work is judged on the accuracy of the dimensions and shape based on the drawings, and the quality of the finish. At the WorldSkills event, competitors repair actual vehicles by beating and welding deformed or damaged body panels.

Car painting

The skill of repairing dents and scratches on the car body requires not just the even application of paint but also masking and color blending techniques. In the international competition, the skill’s definition notes that car painters “may be required to refinish a wide range of items such trains, airplanes, static structures or furniture.”

Plastic die engineering

Participants create dies for producing plastic parts used in household appliances and cars. They use CAD to make drawings and fabricate the die according to the assigned task, competing on the workmanship of the finished plastic product.

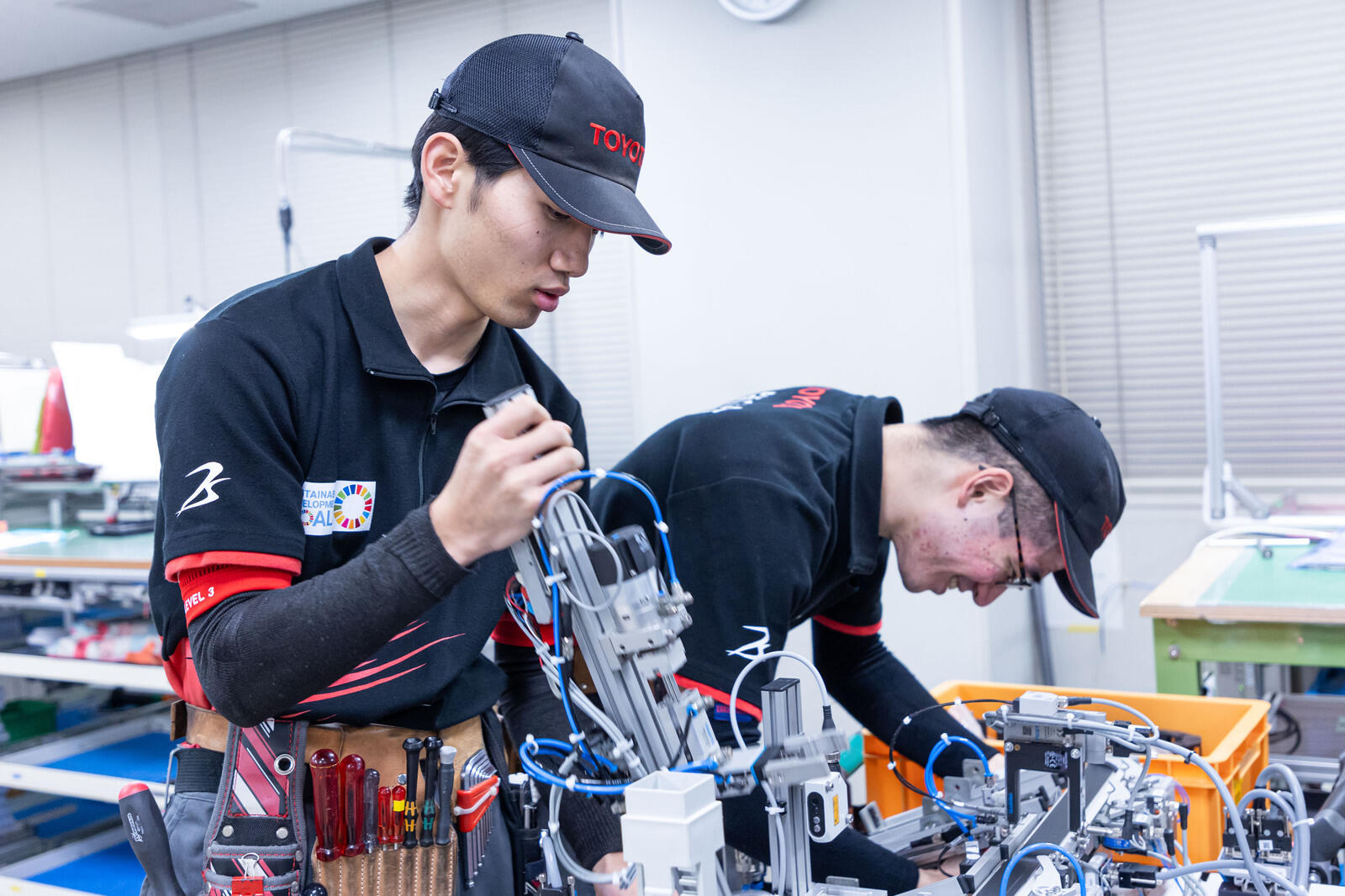

Mechatronics

Working in teams of two, participants design, build, adjust, program, and maintain production equipment resembling that found in industrial factories. Requires interdisciplinary knowledge of machinery, electronics, and other fields; teamwork is also crucial for completing tasks quickly and accurately.

Mechanical drawing & design

This skill entails creating the drawings that serve as the foundation for cars and other mechanical products. Using measuring instruments such as scales and vernier calipers, participants create drawings that contain a range of information, including geometry, dimensions, and acceptable allowance in fabrication.

Prototype modeling

The skill of producing models that can be used to test the design, strength, and other attributes of a product. Competitors craft by hand, with the quality of the results hinging on their ability to interpret drawings, knowledge of materials such as wood and resin, and familiarity with the relevant tools.

Each skills category features multiple tasks, with some announced in advance and others unveiled on the day of competition, testing both proficiency and adaptability.

All eight gold medalists at the national and international competitions are graduates—albeit in different years—of the Toyota Technical Skills Academy, an in-house training facility. Toyota selects participants from the time they are enrolled at the academy. After graduation, they join the Toyota Monozukuri Development Division’s Skill Competition Section, where they hone their skills under the guidance of instructors in their respective occupations.

In December 2024, Toyota Times sat down for a chat with the cohort of gold medalists. We asked about their paths to reaching these heights and their goals for the future.

Growing stronger through partners and rivals

Once again, congratulations on your gold medals.

All Thank you.

Though you competed on different stages—the WorldSkills and National Skills competitions—can you share how you feel now, looking back at the experience?

Aoi Mizuno, Prototype Modeling

In last year’s competition, when carving a sphere, I shaved off too much and couldn’t correct it due to time constraints. I spent this year thinking about that and training to avoid making the same mistake, so it gave me a real sense of accomplishment and fulfillment.

Soudai Yamasaki, Mechatronics

Last year, we were disappointed to finish 29th, nowhere near the medals, so we spent this year training hard. In those twelve months, I think we really grappled with the difficulties of working as a pair (with Karouji). We had a fair few disagreements and fights. At times, our training ground to a halt, and we were left wondering what to do, but we both shared the ambition of winning gold. Of course I’m pleased with the result, but above all I was thrilled that we were able to win together.

Among this year’s gold medalists, mechatronics was the only team category. Was there anything particularly difficult or enjoyable about working as a pair?

Ouga Karouji, Mechatronics

I think so. In terms of difficulties, I am not a very social person, so that felt like a challenge. I had to face up to something I’m not good at, but we managed to keep a healthy distance…

All (Laughing)

Karouji, Mechatronics I’m not particularly good at working faster, but Yamasaki is quick enough to cover for me in that respect. On the other hand, I’m better at figuring out circuits, and I think it worked well that we were able to split up the task and concentrate on our own work.

Morioka, you were nodding your head at those comments. Mechanical drawing & design is a solo discipline, but how did you feel?

Yuki Morioka, Mechanical Drawing & Design

Mechanical drawing & design is an individual competition, but I had some incredibly talented classmates and had to work hard to get ahead. Without them, I don’t think I would have gotten good enough to win a gold medal.