Super Taikyu Series Round 3 is the Fuji 24 Hours. Currently Japan's only 24-hour race, this annual festival of motorsports draws racers, fans, as well as like-minded peers from many fields. We caught up with them on race day.

Partners in carbon neutrality

Super Taikyu has also set up the ST-Q class for development vehicles that have been approved by the STMO. Car manufacturers of all stripes have jumped on board.

To explore the potential of a hydrogen society, TGRR races the GR Corolla H2 concept, which is powered by a liquid hydrogen-fueled engine and has attracted attention from around the world.

From this round, the team also announced that its GR86 Future FR concept would be running on low-carbon gasoline (E20). Together with Mazda, Subaru, Nissan (NISMO), and Honda, TGRR is taking on the challenge of honing its cars in tandem with the new fuel.

Speaking about the importance of pursuing carbon neutrality through Super Taikyu, President Tomoya Takahashi of TOYOTA GAZOO Racing (TGR) said, “The purpose of doing this in the motorsports arena is to make people aware of other ways to reduce carbon emissions.”

True to these words, the Super Taikyu event space hosted various like-minded peers from outside the world of racing, all striving to create a carbon-neutral society.

Among them was Komatsu, which unveiled a 20-tonne hydraulic excavator powered by fuel cells (FCs), bringing decarbonization to the construction site.

The excavator is equipped with a Toyota-made FC system and tanks. These fuel cells power a hydraulic pump, generating oil pressure and flow to move the cylinders and motors, which drive the arm into the earth.

One scoop can dig out 8 m3 of soil. The FC system also moves the machine’s tracks, for a top speed of 5.5 km/h.

Decarbonizing the construction sector

“Around the world, we are seeing similar moves to decarbonize construction and mining machinery,” explained Komatsu CTO (Chief Technology Officer) Taisuke Kusaba and Toyota Vice President Hiroki Nakajima at a roundtable focused on delivering hydrogen.

CTO Kusaba

Whether it’s construction, mining, or industrial machinery, the wave of carbon neutrality is surging forward. Like Toyota’s multi-pathway approach, Komatsu is also pursuing various initiatives.

We can divide these broadly into internal combustion engines (ICE) and non-ICE, which include batteries and the FCs on display at this event.

As for ICEs, we are also researching and developing ways to use hydrogen in conventional engines, just like the hydrogen-powered Corolla.

Right in between the two there are what we call “bridging technologies,” such as alternative fuels and hybrids, and we are working hard in this area as well.

However, technological development is extremely challenging. At Komatsu, we are pushing in all directions as part of a multi-pathway strategy, and one of the keys is getting energy to where customers need it.

Customers cannot use our machines without energy. At present, these are either diesel or gasoline engines, but prices have settled considerably, and for a fuel to be feasible it needs to be delivered on demand.

The FC hydraulic excavator we have here today has a top speed of 5.5 km/h. You can’t drive it to a hydrogen station. If it runs out of hydrogen, the customer’s operations come to a halt, which would be a serious blow.

For that reason, we’ve had extensive discussions with Toyota about the need to deliver hydrogen to our customers. The efforts being made by Toyota can also be incredibly effective in our construction and mining industries.

Our machinery is used in the mountainous terrain of the forestry sector, or for civil engineering projects, land development, and demolition work, all of which take place far from urban areas.

Naturally, there are no gas stations, so fuel must be transported to these locations.

Temperatures range from minus 40 degrees in the coldest places to around 55 degrees. We have machines operating in underground mine shafts below sea level, and others on mountains as high as 4,000 meters.

We need to develop machines that can function in such harsh conditions, while also delivering the energy to power them.

As I mentioned, we are also working on batteries. We have battery-powered hydraulic excavators in the 20-tonne class already being used by customers.

Among other options, however, there is hydrogen, and beyond that various energy sources such as ammonia. At Komatsu, we want to continue broadly pursuing the full range of alternatives.

If energy can reach customers, I believe that will open up many possibilities, enabling construction and mining equipment manufacturers to provide value in different ways.

Komatsu will keep striving to provide solutions for clean, safe, and highly productive work environments. In the process, we hope to create value by developing and supplying machinery that customers can trust.

I believe being able to swiftly and readily deliver hydrogen to all kinds of work sites would transform the world.

To date, we have seen Toyota and other Japanese companies leading the way in such efforts.

While closely following global developments, Komatsu is similarly committed to pursuing this initiative with urgency.

Vice President Nakajima

We were looking for a way to assist in efforts that expand customer options. For those who cannot get to a hydrogen station or cannot refuel unless they are next to a station.

Even here in Super Taikyu, we have constantly pushed ourselves to find the best way of transporting hydrogen. As a result, we created a next-generation JAF road service vehicle that can directly supply hydrogen.

While it is great to have hydrogen-powered passenger cars driving around town, the moment they run out of hydrogen they’re completely stuck.

In the past, one of our FCEV trucks was caught in a traffic jam due to an accident and had to be towed after running out of hydrogen.

The sight of an FCEV, a car that should represent the future, being towed away is not something I wanted to witness again, which is why we coordinated with JAF to build this service vehicle.

With these kinds of solutions, we have been exploring the idea of delivering hydrogen for use in equipment at construction sites and various other genba.

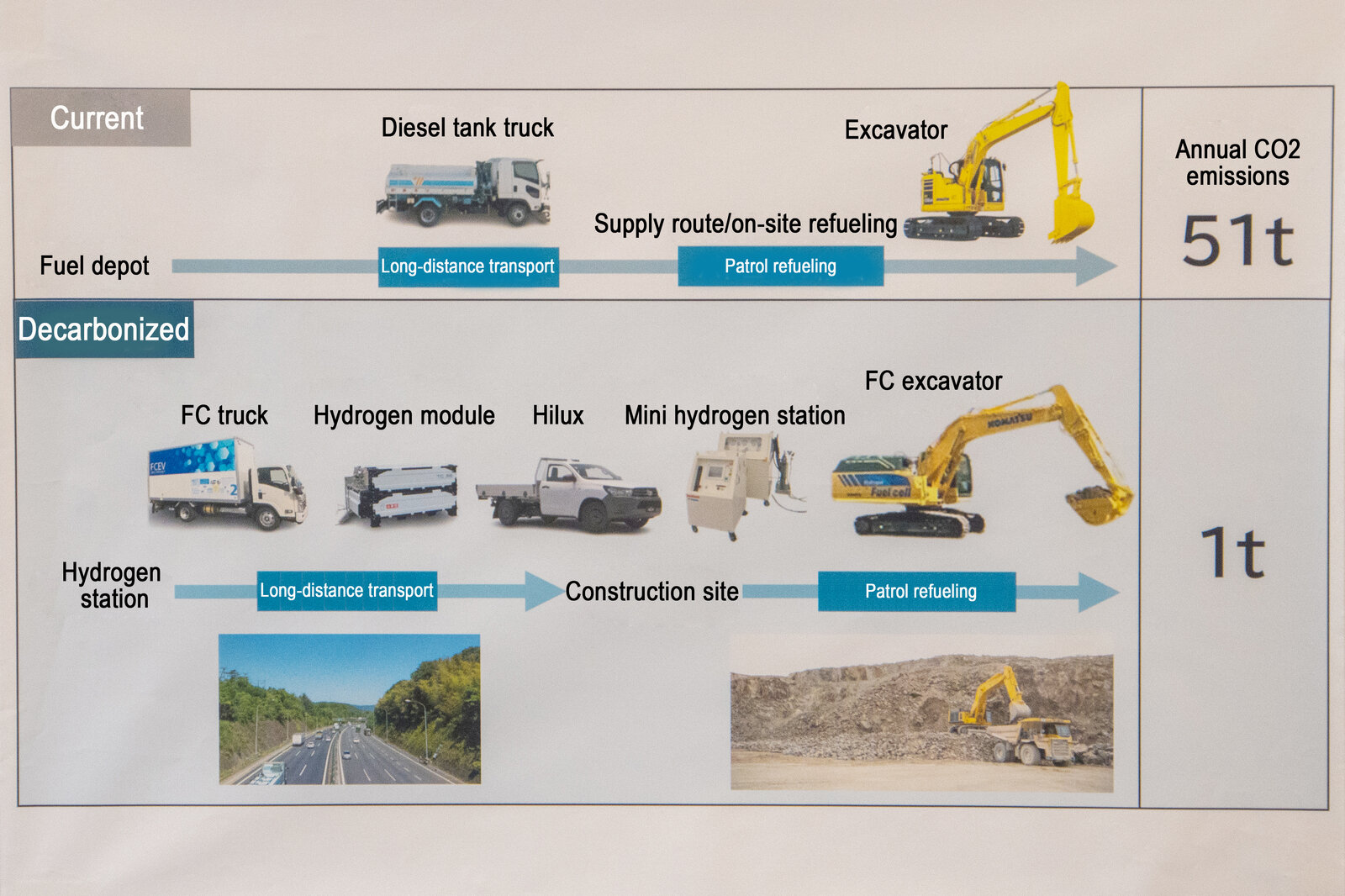

For equipment that runs on diesel, I am told that tank trucks bring the fuel to the vicinity of work sites, where it is then used to refuel the machinery operating at these locations.

In the case of carbon-neutral excavators such as this one, hydrogen cartridges and a compact hydrogen station could be set up on the flatbed of our Hilux, for example, which is capable of navigating rough terrain. The idea is that these Hiluxes could refuel excavators in the same way as JAF’s next-generation road service vehicles.

Although the figures will vary greatly depending on usage conditions, purely as a reference, one customer currently emits around 51 tonnes of CO2 annually.

In this scenario, by using an FCEV truck, FC excavator, and diesel Hilux to handle rough terrains—we are trialing an FCEV Hilux, but unfortunately this is not yet available as a product—CO2 emissions would total just one tonne.

One of our hopes with this construction machinery is that, since they consume large amounts of fuel, they can boost hydrogen utilization.

Commercial and industrial vehicles work hard, which means they consume a lot of hydrogen.

The key to building the hydrogen society of the future is establishing a market with stable hydrogen consumption.

To achieve this goal, at Toyota we started from passenger cars. However, when this alone did not lead to stable demand at stations, we established a framework for commercial vehicles, called the Commercial Japan Partnership Technologies Corporation (CJPT), through which we are collaborating with various companies.

It is deeply reassuring to have the construction machinery manufacturer Komatsu join us as a new partner and trusted ally in this collaboration.

While the concept still exists only on paper, by deploying these hydrogen excavators in the genba we hope to refine our vehicles for delivering fuel, thereby bringing us one step closer to the creation of a hydrogen society.

I hope you will appreciate that the technologies for delivering hydrogen we have cultivated here in Super Taikyu are taking another big step forward toward a new vision.

Dreams of digging up natural hydrogen

Vice President Nakajima wrapped up the roundtable discussion by saying, “Lastly, may I share a dream with you?”

Vice President Nakajima

At present, the price of hydrogen remains high, and naturally, as a country that lacks energy, the ideal solution for Japan would be to produce it through water electrolysis.

It would be best if this could be done using electricity that doesn’t generate CO2 emissions, but recently natural hydrogen has also come into the spotlight.

In Australia, hydrogen with 97% purity is simply being dug out of the ground. At the same time, this also yields helium, which has industrial uses.

With Komatsu, my dream is to find hydrogen underground in Japan, dig it up, and use it to power these construction machines! I hope we can do this together.

CTO Kusaba

We certainly have the digging equipment covered (laughs).