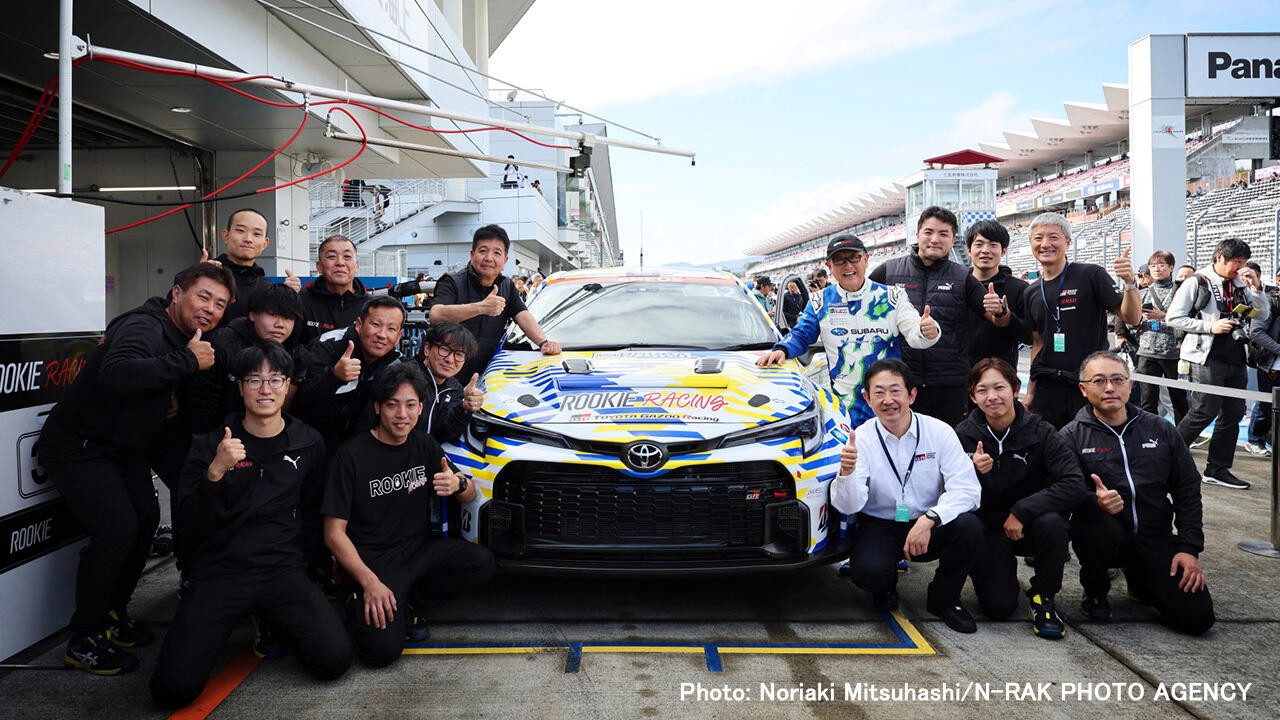

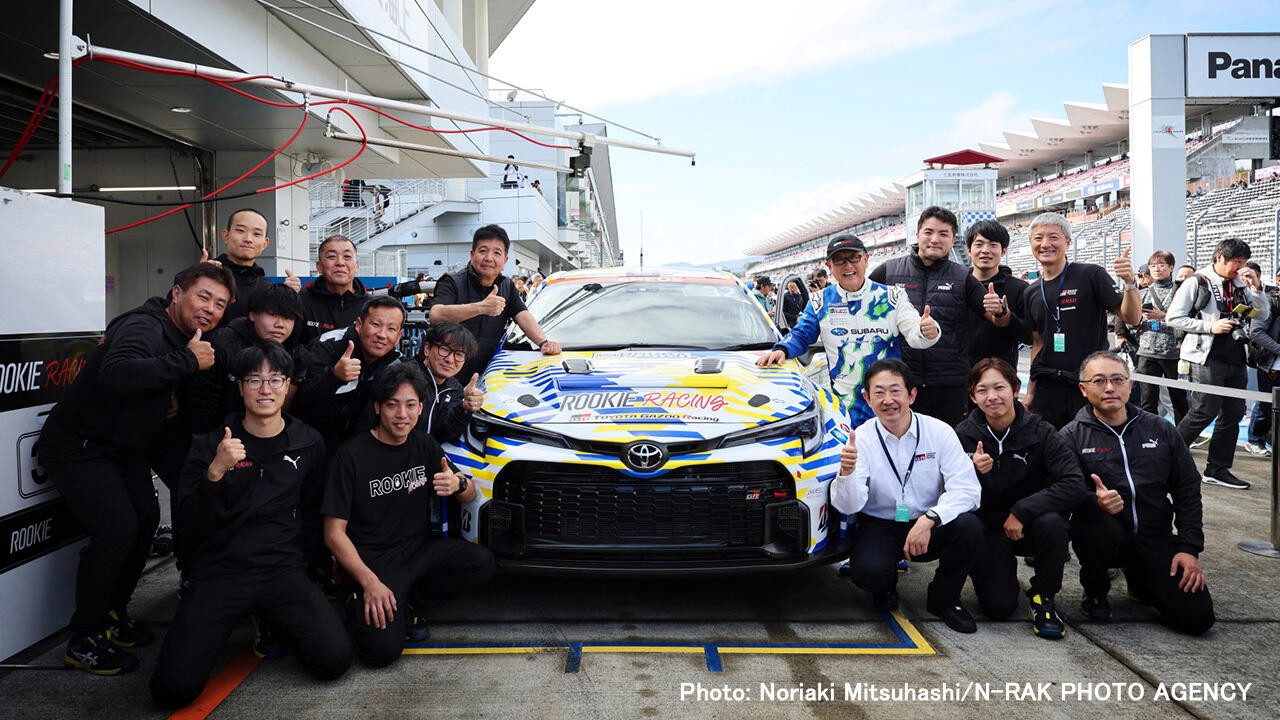

With Chairman Akio Toyoda (aka Morizo) behind the wheel, the liquid hydrogen Corolla project is pioneering new options for decarbonization. More like-minded partners are heeding the call.

On November 17, the 2024 Super Taikyu Series wrapped up with the final round at Fuji Speedway in Oyama, Shizuoka.

It was a turbulent race, with two red flags and stoppages accounting for half of the four-hour event, but ROOKIE Racing’s #1 Zhongsheng ROOKIE AMG GT3— driven by Ryuta Ukai, Giuliano Alesi, Naoya Gamo, and Tatsuya Kataoka—prevailed to take the overall victory. In a dramatic turnaround, the team came from third place to clinch the series.

Meanwhile, the #32 ORC ROOKIE GR Corolla H2 Concept, running on liquid hydrogen, has been testing a volume-efficient elliptical tank and more durable fuel pump since the Fuji 24-hour race in May.

Although the havoc on the track did not allow the team to pursue its original goal of three pit stops, the Corolla managed to complete its first race of the season. With improved range, #32 needed just two stops to finish the race, the same as gasoline-powered cars.

Although the 2024 season has drawn to a close, development continues without pause. In search of further advances, the team called to potential new partners during the race.

Naoaki Ito, Project General Manager (Hydrogen Engine Project), GR Vehicle Development Division

In 2021 and 2022, we honed our hydrogen engine and car using gaseous fuel, bringing performance on par with gasoline engines within two years.

From 2023, we turned our attention to technologies for carrying hydrogen, switching to liquid fuel to increase range.

I regard 2023 and 2024 as the “first half” in developing the technologies that underpin liquid hydrogen, such as tanks and pumps.

Now, as we take on the second half, we will encounter an even greater level of technical difficulty. Once again, we hope to bring more partners on board and mobilize Japanese technologies to tackle these challenges.

In the words of Chairman Akio Toyoda, “Motorsport is a laboratory that anyone can peek into... to create a hydrogen society, we need to make it easier for everyone to get involved.”

To move hydrogen’s image from something dangerous associated with explosions, Morizo has personally sat behind the wheel and led the way in building partnerships.

In this article, we look at the technologies these partnerships will tackle in the lead-up to next season, and Toyota’s vision for the project’s future.

Harnessing discarded hydrogen

As explained in previous articles, the liquid hydrogen Corolla’s fuel is kept at an ultra-low -253℃. This temperature is maintained by placing the hydrogen in tanks with a double-shell vacuum-insulation structure—picture a thermos flask—thus keeping the fuel in a liquid state.

Unfortunately, heat can enter via the fuel pump and other parts that penetrate the tank walls, causing the hydrogen to gradually vaporize. This generates what is known as boil-off gas, meaning vaporized hydrogen.

During driving, the unsettled fuel movement inside the tank creates more boil-off. Until now, the team had safely treated this vapor, including using catalysts to convert it to water. However, this means less hydrogen is available as fuel, resulting in wasted energy.

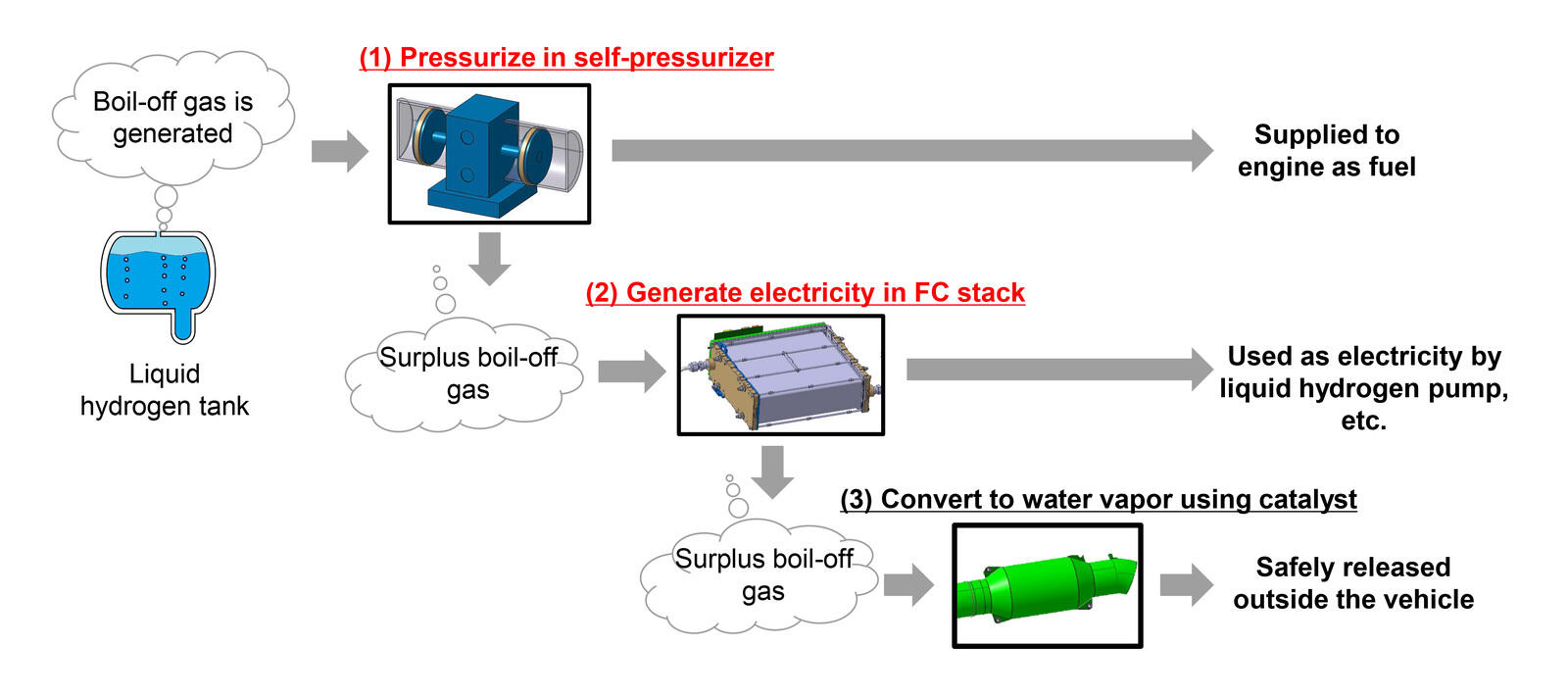

In the “second half” outlined by Project General Manager Ito, the team will develop technologies for reducing, utilizing, and treating boil-off gas, which until now had simply been discarded.

To help things along, they have decided to put out a call for partners with strengths in utilization and treatment technologies.

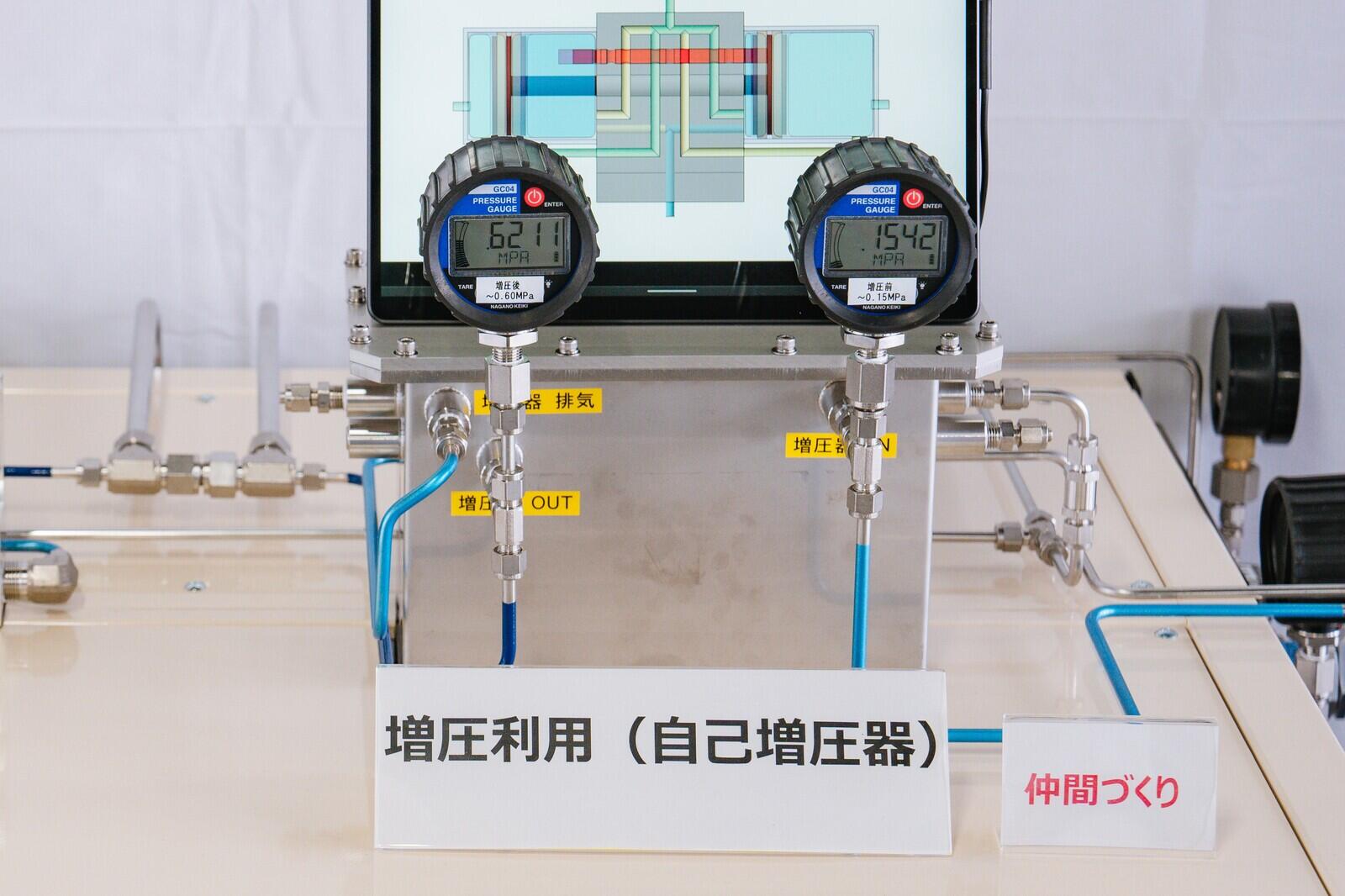

Utilization technology: 1. Compressing fuel with a self-pressurizer

A self-pressurizer is a device that can increase the fuel’s pressure without requiring electricity or other forms of energy. As boil-off gas, the hydrogen’s pressure is too low to be used by the engine.

The goal is to reuse this hydrogen as fuel, and a self-pressurizer assists by delivering a two- to four-fold boost in pressure.

Although an onboard hydrogen self-pressurizer for vehicles does not yet exist, the technological pursuit is underway.

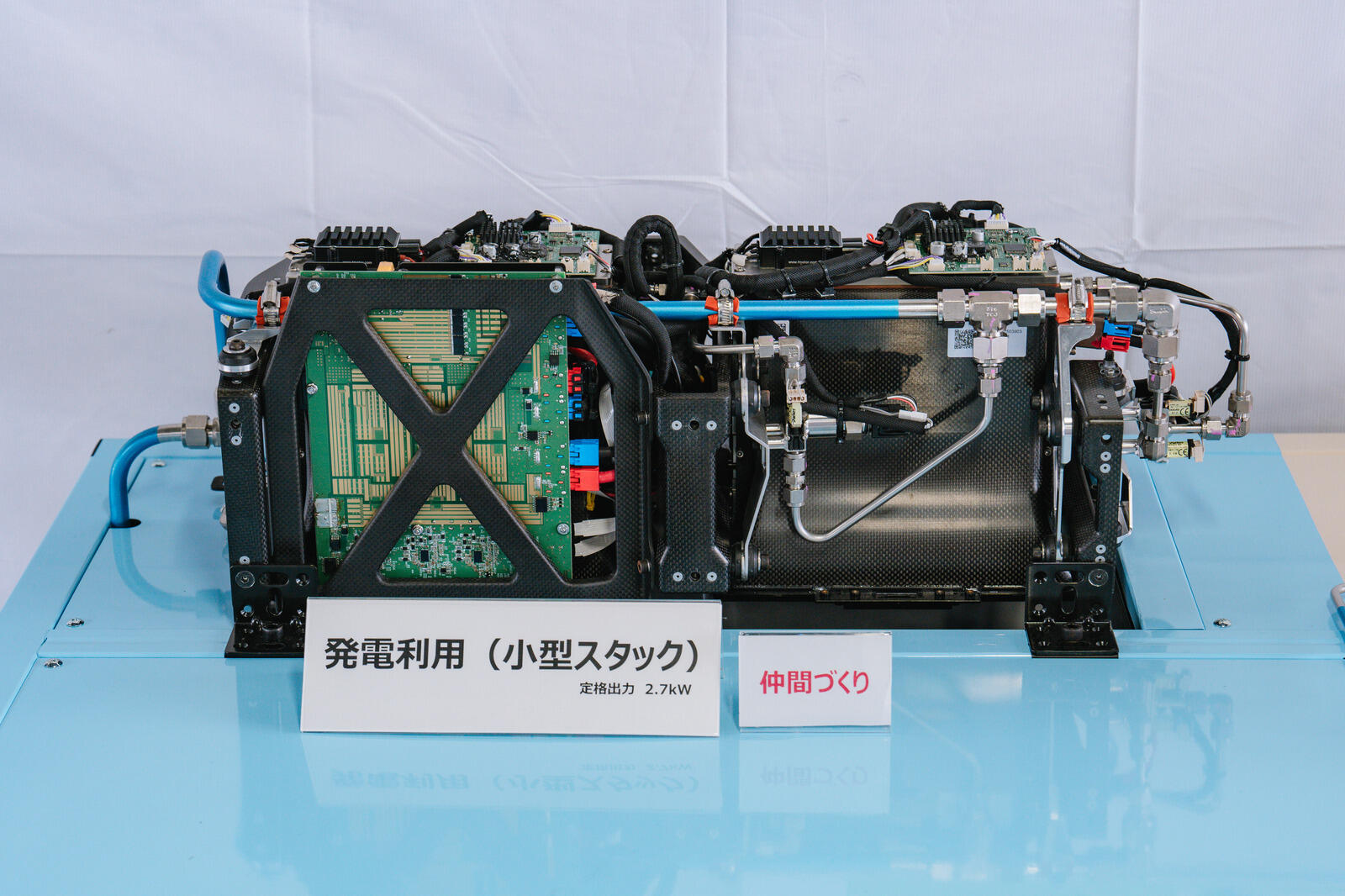

Utilization technology: 2. Generating electricity via an FC stack

Toyota is developing fuel cell (FC) stacks that are more lightweight and compact than those which power FCEVs like the Mirai.

These units will generate electricity through chemical reactions between oxygen in the air and surplus boil-off gas not used up by the self-pressurizer.

The idea is to use this electricity to power equipment such as the pumps that deliver liquid hydrogen, thereby boosting the car’s overall energy efficiency.

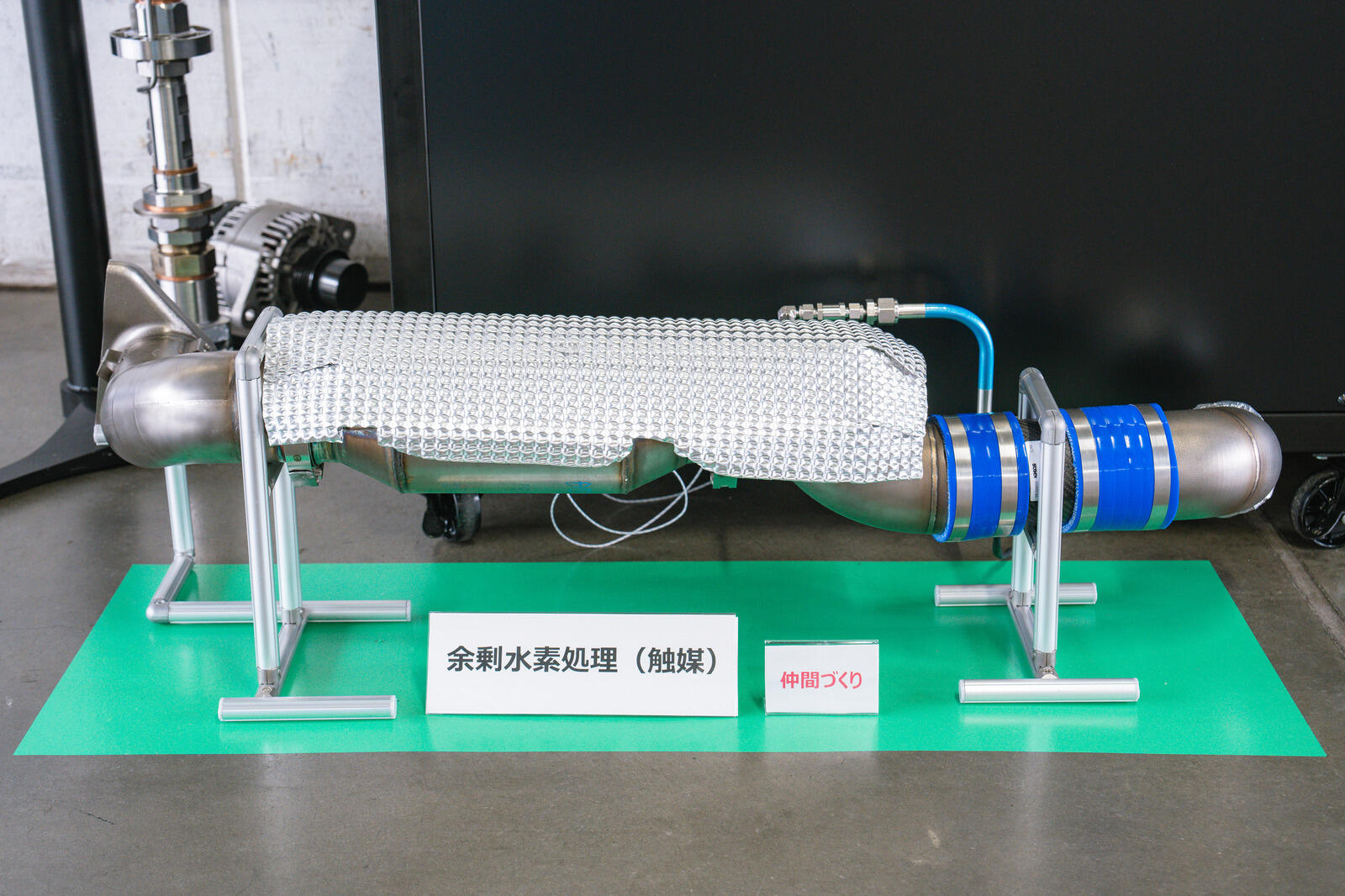

Treatment technologies: 3. Conversion to water vapor by catalyst

Any remaining hydrogen that is not used by the self-pressurizer or FC stack is converted into water vapor via a catalyst, then safely released outside the vehicle.

Toyota is looking for partners to speed up the development of these three technologies so that they can be rolled out in next season’s races.

Our explanation has skipped over the third aspect: Toyota’s approach to reducing boil-off gas. In May 2023, the team announced its superconducting technology.

Superconductivity is a phenomenon in which electrical resistance vanishes at ultralow temperatures. If the pump motor and drive components can be placed inside the -253℃ tank, the absence of electrical resistance could allow them to be made smaller and lighter.

Doing so would also help eliminate paths of heat transfer that penetrate the tank walls, reducing boil-off gas by perhaps half.

Development of this superconducting technology is proceeding at a rapid pace, with a view to implementation in the coming season.

Calling all companies that enjoy a challenge!

Project General Manager Ito

In 2022, with the liquid hydrogen car still unfinished, we put the technology on display (at a racetrack) to show what we wanted to do.

We put the call out for companies to help fill the gaps in our technologies. Many jumped on board, and within a year the liquid hydrogen car was up and running. We hope to do the same this time around.

This is how Ito describes his ambition.

As they try to bring several new technologies into the world, what do Toyota’s engineers seek from their partners—technical prowess? Quality? Or perhaps cost improvements? Project Manager Ryosuke Yamamoto shares his hopes.

Project Manager Yamamoto

We’re looking for partners who enjoy a challenge. Cost and other factors will fall into place later, but to begin with we want people who are eager to work together on something new, to help speed up development.

The liquid hydrogen Corolla project is pioneering new options for decarbonization. Since the season finale, multiple companies and organizations have already gotten in touch.

With sights set on major advances in the coming season, Toyota’s partnership-building efforts are shifting up a gear.