From certification issues to long delivery times, many shareholders are anxious about problems affecting not just Toyota, but the entire auto industry. Vice Presidents Hiroki Nakajima and Yoichi Miyazaki responded to questions about cultural reforms and collaboration with dealerships.

J-SLIM

Due to certification issues, Toyota temporarily halted production of certain models until they complied with the standards. Some shareholders questioned whether the company had coordinated with its dealers.

Executive Vice President Yoichi Miyazaki responded by outlining Toyota’s efforts to improve long delivery times.

Vice President Miyazaki

I think this question truly represents the concerns of both our domestic and global customers.

Amid chip shortages in the wake of the pandemic, we could not keep up with orders, forcing customers to wait for their vehicles. Our desire to deliver cars as quickly as possible placed too much pressure on the genba, and I believe this contributed to the certification issues.

Not wanting to keep customers waiting, our genba staff worked themselves a little too hard. This came at the expense of quality and safety in various areas, ultimately leading to a stop in production.

Prior to this response, Vice President Miyazaki had answered a question from another shareholder, regarding Toyota’s approach to carmaking.

“Our fundamental carmaking priorities are safety, quality, volume, and profit, in that order. We strive to produce happiness for all customers. The driving force behind these efforts is people. By properly cultivating our people, we hope to maintain the safety and quality that I just mentioned.”

At the announcement of Toyota’s second-quarter financial results for the fiscal year to March 2025, Vice President Miyazaki emphasized that the company had “no reservations” about increasing investment in personnel. Now at the general meeting, he reiterated the commitment to developing human resources and improving working environments in order to ensure safety and quality.

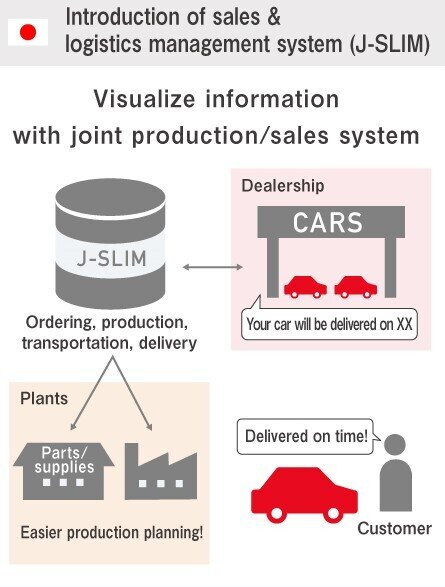

Which brings us back to the question of long delivery times. Vice President Miyazaki explained the Japan Sales Logistics Integrated Management (J-SLIM) system, devised to facilitate coordination between manufacturers and dealers.

Vice President Miyazaki

As you have rightly pointed out, our dealers are also understaffed and unable to operate to their full extent. Where people are involved, there may also be time lags or errors in the information we provide to dealers.

We therefore introduced a new domestic system, J-SLIM, that allows manufacturers and dealers to manage the same information. Specifically, the moment a customer places an order at a dealer, this information is sent to the manufacturer.

The manufacturer then informs the dealer of the delivery time for that car, facilitating negotiations with the customer. This is an example of the improvements we have made.

J-SLIM is still a work in progress. While it is far from perfect, we plan to use customer suggestions and feedback as a springboard for improvement and will continue working to boost customer satisfaction.

Since honest customer feedback serves as a driving force for improvement, we hope you will continue to push us forward by providing your support and suggestions.

While collaborating with dealers, Toyota is also working to shorten delivery times by harnessing automation and digital solutions in the production genba.

In their answers, both vice presidents spoke of “work in progress.” The ideal state may not yet have been reached. Viewed another way, however, this also means that Toyota is steadily making progress towards its goal of producing happiness for all.

At the genba, the pursuit of improvement continues.