The Creative Idea Suggestion System makes work more fun and interesting. In this article, we showcase an ingenious idea that employed the "nori punch" mechanism to instantly simplify a detailed task, previously done with cutters and hammers.

“Surely there’s an easier way?”

“I was assigned to this role after coming back from maternity leave,” explains Ayami Toyomaki of Facilities Maintenance Section No.2, Driveline Manufacturing Division 2 at Toyota’s Miyoshi Plant. “Having to use the utility knife was a real pain and always frustrated me. I thought, ‘Surely there’s an easier way?’”

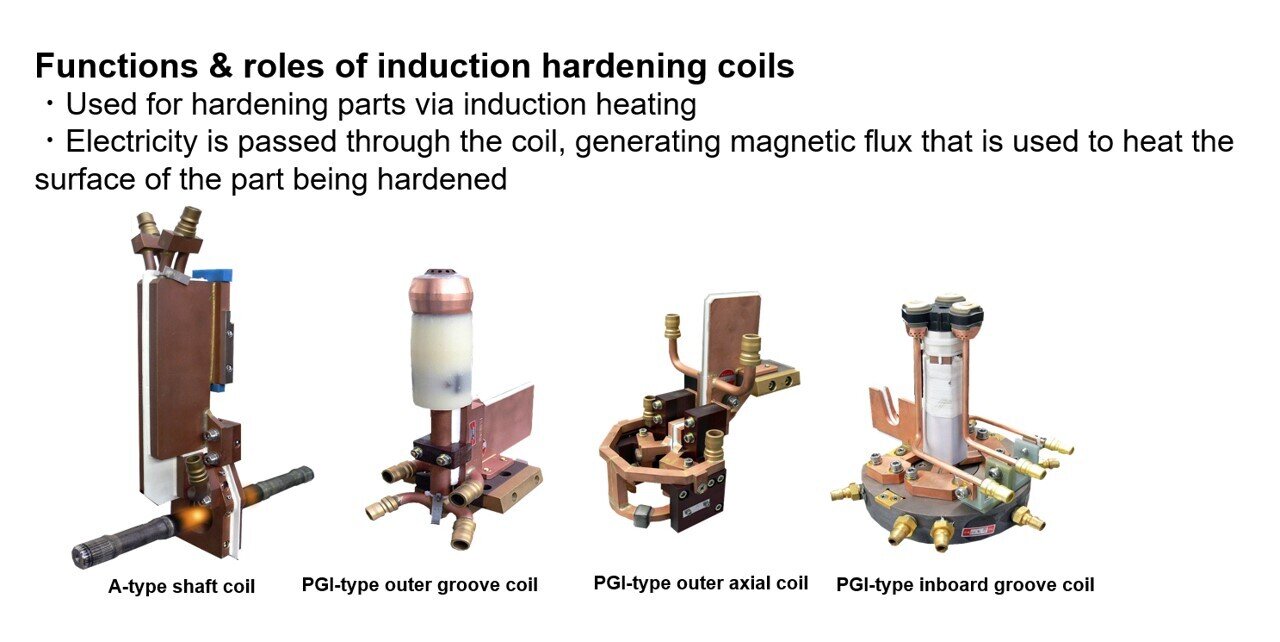

The team that Toyomaki belongs to is tasked with refurbishing and maintaining equipment in production facilities, and her role involves looking after the induction hardening coils.

First, some information on these coils.

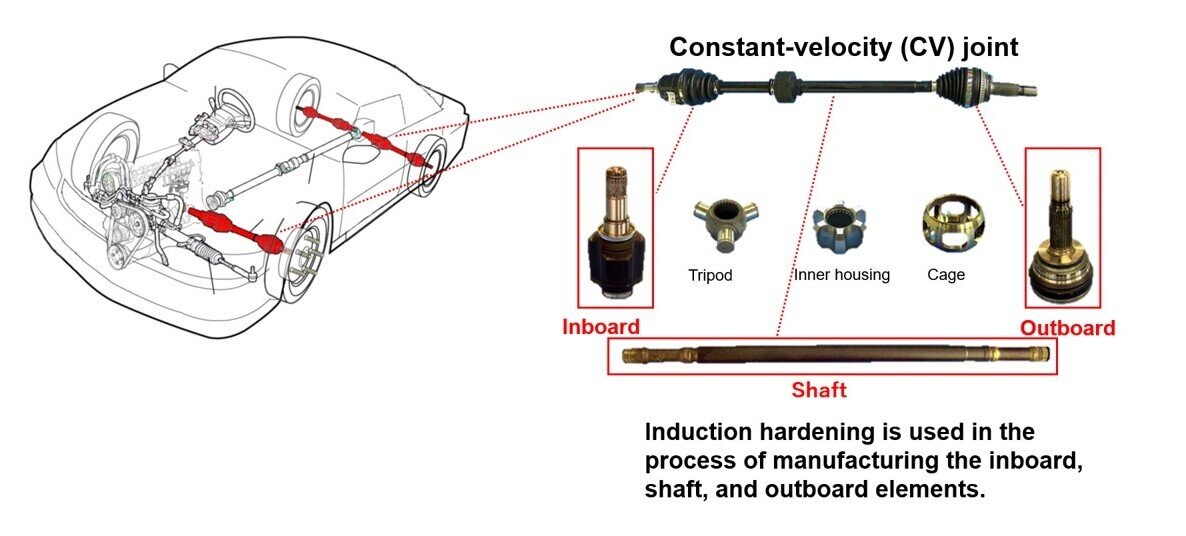

Constant-velocity (CV) joints, which transfer the engine’s power to the wheels, have various components including the inboard joint, the shaft, and the outboard joint. The manufacturing processes for these parts include a heat treatment step called induction hardening. This is where the coils come into play, and Toyomaki is in charge of keeping them operational.

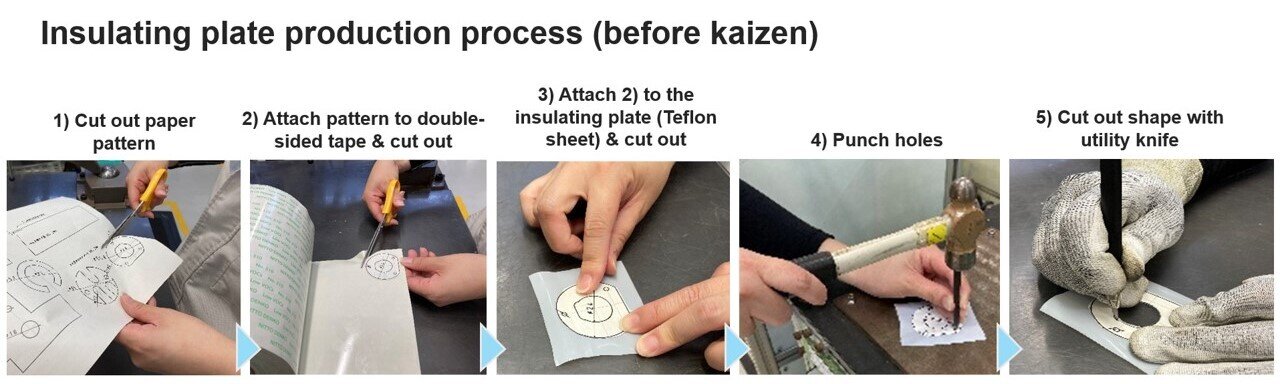

Induction hardening coils contain insulating plates that vary in shape for each different coil type, and these must be prepared anew whenever refurbishment work is undertaken. The plates come in a range of sizes and thicknesses, with some created out of 0.2 mm Teflon sheets.

The creative idea suggested by Toyomaki was related to these 0.2 mm insulating plates.

Previously, the plates were made by hand as shown below, a task made difficult by the thin Teflon sheets, the tiny cutouts required, and the complex shapes.

Ayami Toyomaki

One day, I half-grumbled to our team leader, ‘Couldn’t we make something like the nori punches used for lunch boxes?’

It’s not like I had been working on the nori punch idea—the words just popped out when I tried to explain the fuzzy picture in my mind.

To her surprise, the team leader responded with, “I think we could!”

As the name suggests, a nori punch is a device used to stamp out pieces of nori (dried seaweed). A convenient accessory when preparing lunch boxes in Japan, it works by inserting and pressing down on the nori to cut it into various forms, from faces to shapes, animals, and cartoon characters. It is a must-have when trying to jazz up a child’s lunch box.

The punch that saves 22 work hours per month

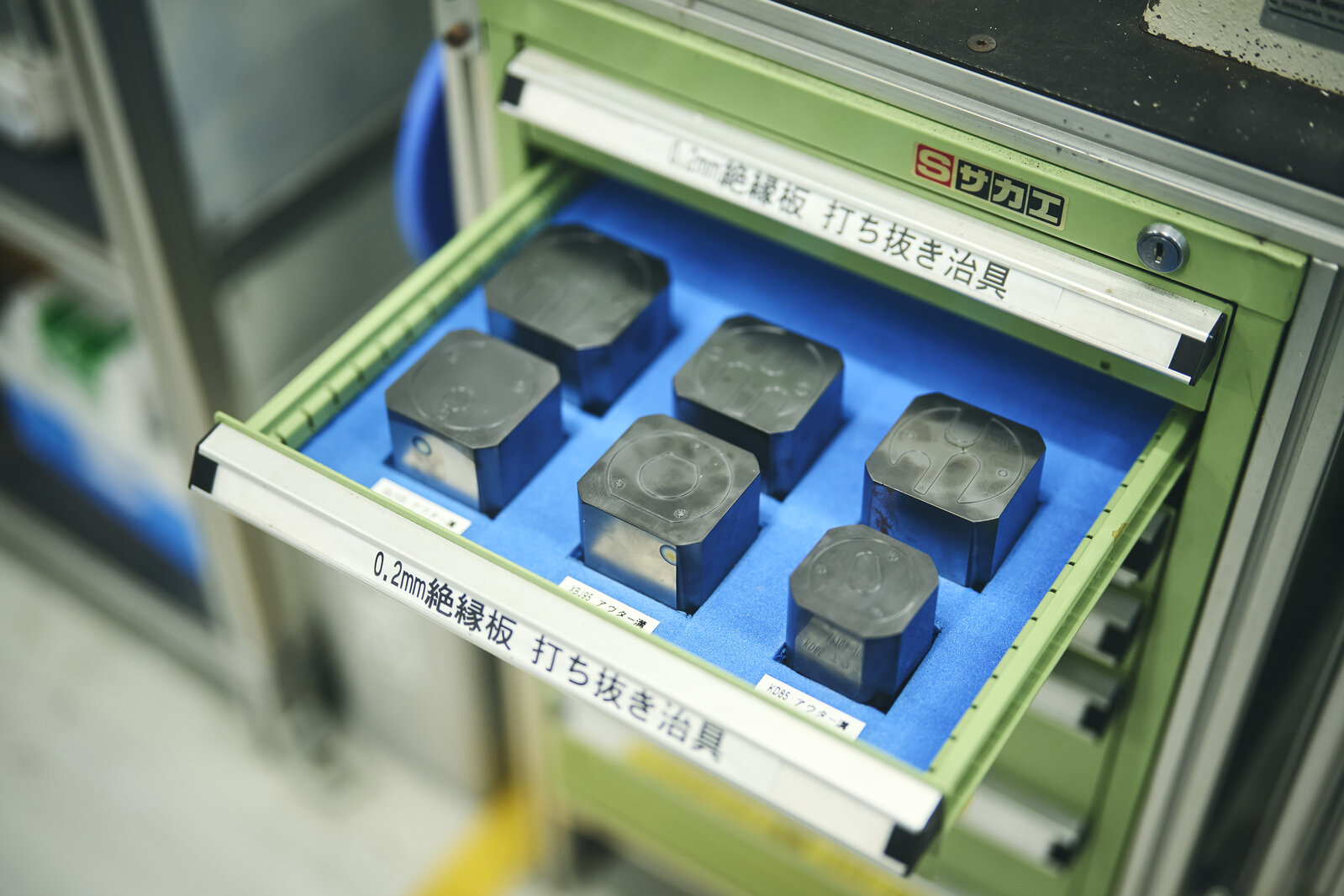

Toyomaki’s team leader was convinced that a hand press could do the job in a single motion and swiftly drew up the blueprints. By enlisting the plant’s machining technicians, even the production of dies proceeded at astonishing speed.

Although adjusting the width and height of these dies proved more troublesome, within roughly a month of coming up with the concept the team had perfected the insulating plate punch.

This is how the plate production process looks with the new punch:

An intricate, complex task can now be easily performed by anyone, with identical results.

The result is a saving of some 22 work hours per month. This ground-breaking kaizen also improves safety, eliminating the risk of workers cutting their hands with utility knives.

Toyomaki’s insulating plate punch received the top award within the Creative Idea Suggestion System and was even mentioned by President Sato during a New Year’s message to Toyota employees.

One of the reasons for all this attention was the idea’s “nori punch” origins, epitomizing the work of a mother balancing her job and child-rearing.

“Everyone simply accepted the task as a given, without so much as considering how dangerous it was to cut thin sheets with a utility knife,” says Group Leader Takeshi Tanaka. “Then along came Toyomaki’s idea to improve the situation. The nori punch idea would never have occurred to me!”

Serving the company while striking a work-life balance

Ayami Toyomaki

Because I had reduced my hours after maternity leave, I sometimes wondered whether I was contributing much to the company. I was really pleased to be useful in this way, and to be recognized for it. I was also glad to hear that it made work easier and safer for my colleagues.

The award was 40,000 yen, and I received half since it was a joint submission with my team leader. I remember telling my family and then using it as pocket money, but I don’t remember what I spent it on. It didn’t last long (laughs).

In the past, Toyomaki says she “never had much interest in suggesting creative ideas,” but this success has greatly shifted her mindset.

“If a task is hard to do, I now make sure to speak up. From there we can work on improvements, submit a creative idea, and maybe receive a reward (laughs).”

After the insulating plate punch, Toyomaki also received 20,000 yen for another proposal. In addition to submitting creative ideas every month, she says she is also working on something bigger.

Ayami Toyomaki

By exploring different ideas, your problem-solving skills grow. Putting those ideas into words opens up communication with all kinds of people, and working together builds connections with others. I think that’s the appeal of the Creative Idea system.

Finally, we asked Toyomaki what kaizen means to her.

“I think it’s about making tasks easier and safer to create a better workplace for everyone.”