A wooden loom recently transported into Woven City turned out to be a replica of a 136-year-old invention. What does this connection to the past mean in a place seeking to create "the future fabric of life?"

A truck departed at eight o’clock on the morning of March 27, and carefully made the five-hour journey from Toyota's Myochi Plant in Miyoshi, Aichi. It arrived at a quarter past one at its destination, Woven City.

Five men stepped around to its bed to unload its burden: a wooden loom.

That loom was to be unveiled at a ceremony in four days’ time.

As it happens, another also stands at the entrance of the Woven by Toyota offices in Nihonbashi.

What do these looms mean, and why are they found in various places with connections to Woven City? We set out to solve the mystery.

Returning to Toyota’s origins

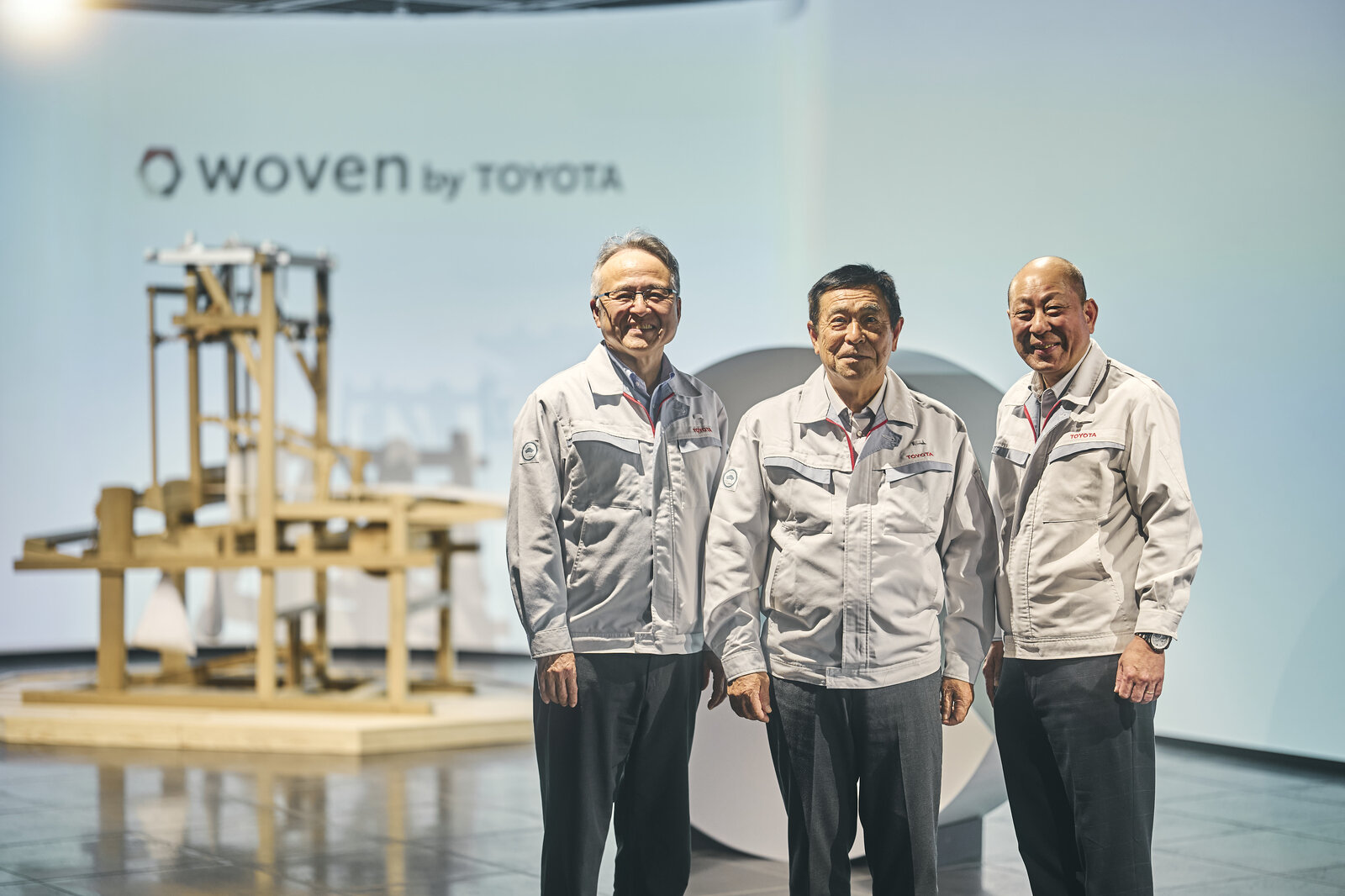

In December 2024, we visited Woven by Toyota after hearing about a special course being organized for the company’s employees.

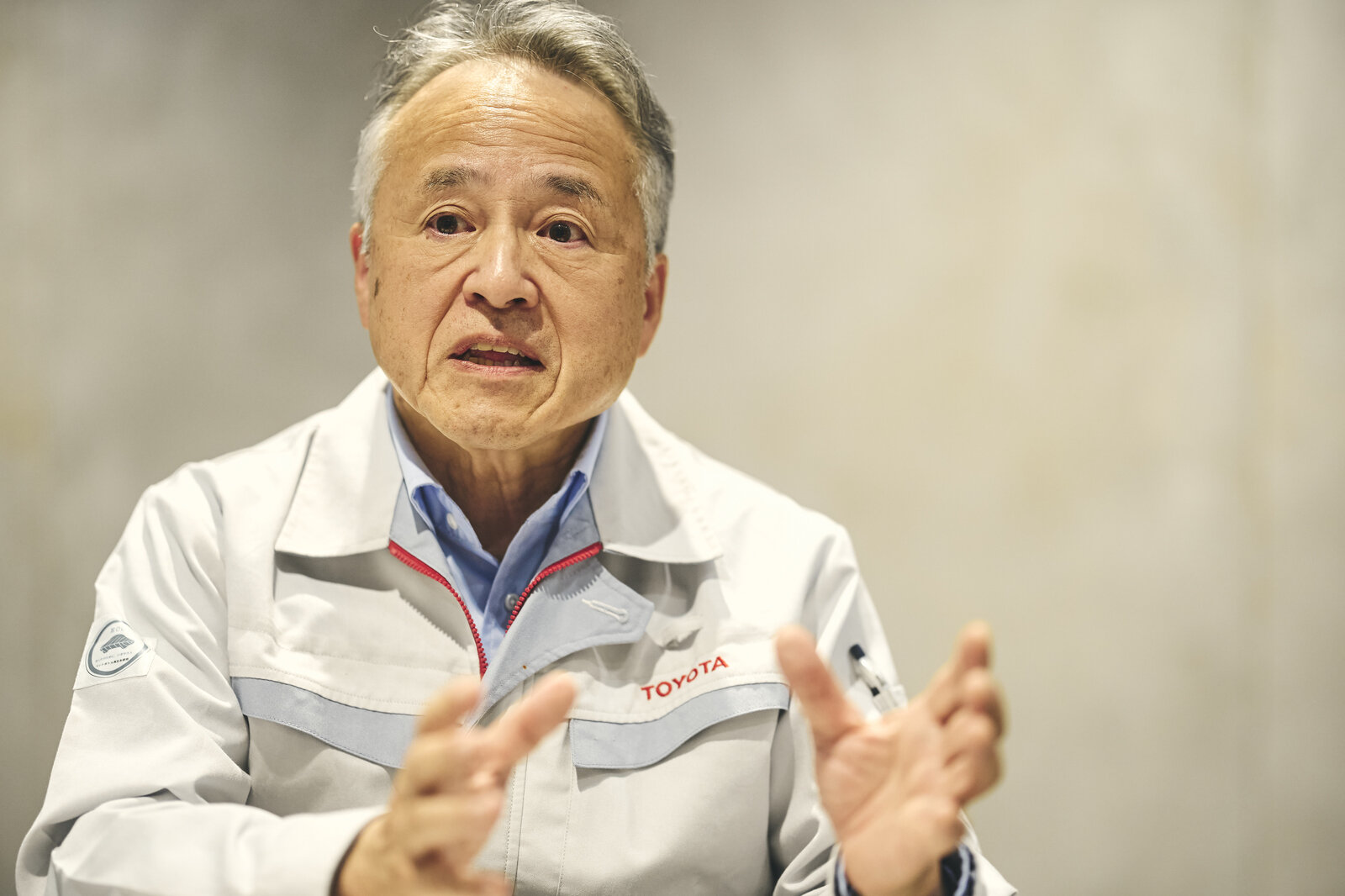

The object that greeted us in the lobby was a reproduction of the Toyoda wooden hand loom invented in 1890 by Sakichi Toyoda, who laid the Toyota Group’s foundations. It had been put on display last July.

This reproduction was the work of Masamitsu Kenmochi. Prior to reaching retirement in February, he had spent 51 years at Toyota, including as a student at the Toyota Technical Skills High School (now the Toyota Technical Skills Academy).

Before retiring, Kenmochi led the wooden mold workshop that helps train technical personnel within the Powertrain Administration Department.

Together with department colleagues Yuji Nishiyama and Tsuyoshi Nanba, he established a course that uses the loom to explore the Toyota Group’s roots.

Although originally intended for Toyota employees, it has already been run four times at Woven by Toyota since April 2023.

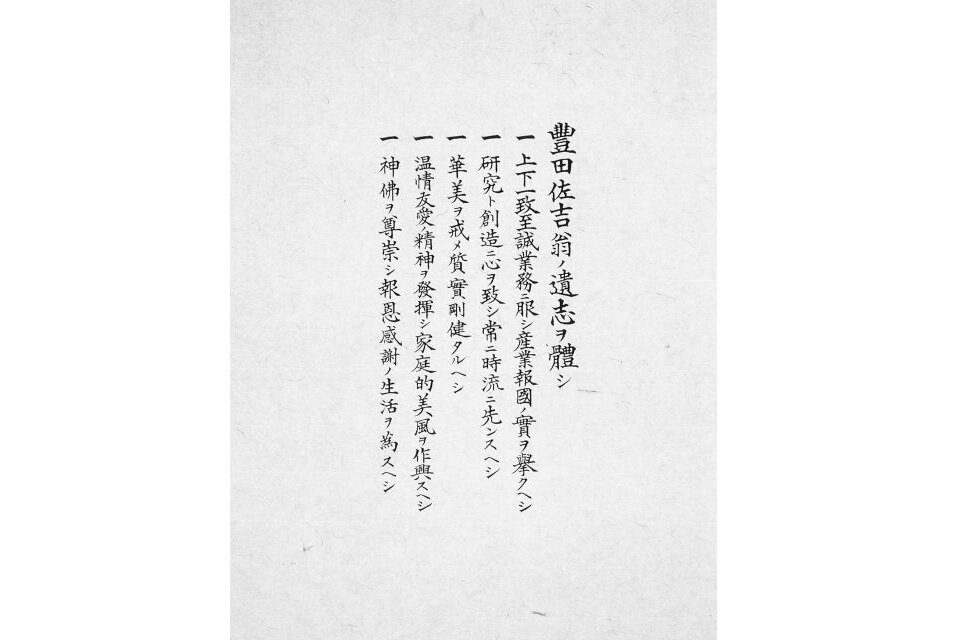

The course begins with classroom lectures tracing Sakichi’s life, which was devoted to inventing the loom for the country's benefit, while delving into the spirit of the Toyoda Principles that encapsulate his philosophy.

The sessions then move to the loom, where participants try their hands at weaving fabric, sharing in the insights and lessons that Kenmochi gained through the process of rebuilding the instrument.

“Building the loom with your own hands gives you an appreciation for how Sakichi-ou* felt,” says Kenmochi.

*Within the Toyota Group, Sakichi Toyoda is affectionately known as Sakichi-ou or great-grandfather Sakichi.

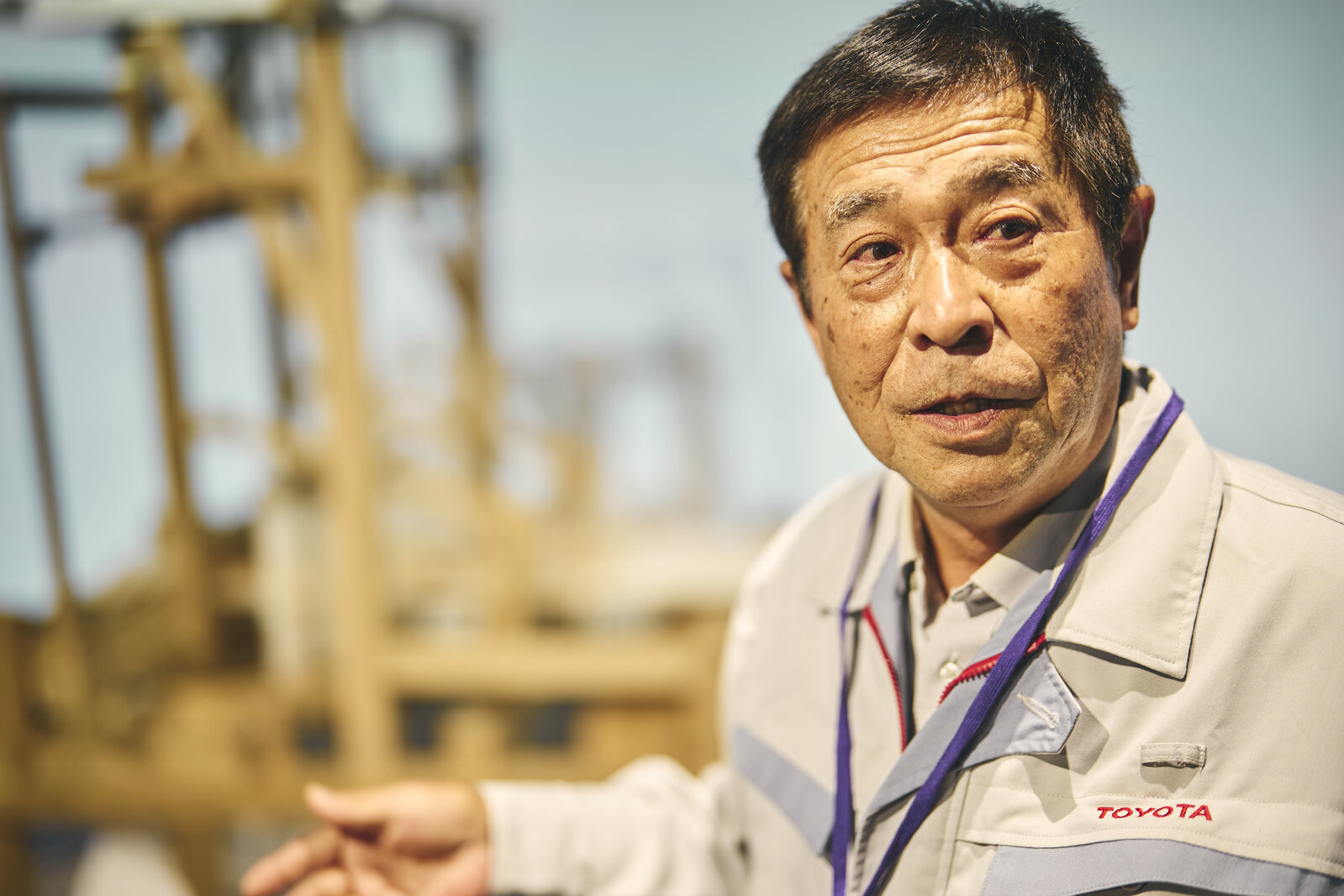

Masamitsu Kenmochi

Sakichi-ou was around 23 when he built this loom. I recreated it after turning 60. Retracing that process, I was struck by his incredible achievement, in terms of his age, vision, skill, everything.

Initially, I sometimes found myself wondering, “Why did he make it like this?” or “Isn’t this just extra effort?” But behind everything is a clear philosophy and message that he wanted to convey.

Nanba also gained insights through the rebuilding process.

“The finished loom produces cloth with an incredibly consistent and uniform weave. It isn’t tiring to operate and is sturdy so it doesn’t break down. Everything contributes to making life easier for the weaver.”

The young Sakichi is said to have invented the Toyoda wooden hand loom to make life easier for his mother, who would toil into the night weaving cloth.

Indeed, his first patent notes that the primary purpose was to reduce the amount of physical effort involved by eliminating the need to hand-feed yarn.

Sakichi’s loom could be worked with one hand instead of two, using a karakuri mechanism to pass through the horizontal thread. The weaver could also wind the cloth without leaving their seated position, which could be adjusted to suit their physical build.

All these mechanisms reflect Sakichi’s desire to make life easier for the user.

In the process of rebuilding, Kenmochi and his colleagues unraveled the innovations and ingenuity that went into Sakichi’s loom.

Instead of learning from documents left behind by others, Kenmochi relied on his own skills, treading the same path as Toyota’s pioneers. It led him to the underlying motivation of working for others.

The course that Kenmochi helped start allows participants to get acquainted with the actual loom that was rebuilt through this process. Through this experience, participants learn that the philosophy valued by Toyota is not just idealistic talk.

Toyota Times went along to the fourth of these sessions at Woven by Toyota, which Kenmochi wrapped up with the following comment:

“Ninety years ago, our predecessors shifted Toyota’s business from looms to automobiles. Today, we are at another point of complete change, into a mobility company. I believe this transformation is underpinned by all of your hard work. Please continue to go forward with pride and courage.”