Toyota's Creative Idea Suggestion System makes work more fun and interesting. This article shines the spotlight on two ideas born out of the unique challenges posed by the Motomachi Plant's high-mix production line.

Making work easier for all

Let us start with the first idea.

One day, a female technician working at Toyota’s Motomachi Plant was assembling components on the back side of an instrument panel, reaching on tiptoe as she worked. Seeing how she struggled, Katsuya Yamashita, then a team leader in Assembly Section No.1, had only one thought.

“This is no good. We need to do something about it.”

A task that gave no trouble to tall workers was difficult for smaller technicians. Being able to rotate the work platform made it doable at a full stretch, but the whole point was that anyone should be able to perform the task smoothly.

The solution that Yamashita devised was a retractable step.

Normally stowed away, the step can be deployed as needed with the push of a lever. This is done via a crank mechanism, with a perpendicular pipe causing the steps to slide out as it rotates. The assembly consists of aluminum pipes, sliders, and springs, achieving a smooth action and compact storage at minimal cost.

Initially, Yamashita tried a rope pull arrangement but gave up on the idea when the step proved too heavy to move. Inspired by a crank mechanism used elsewhere on the line, he continued to improve the design, tinkering at the workbench after his shifts. In total, Yamashita spent some 15 hours completing his creation.

Katsuya Yamashita

You can work hard to make something, but if it’s not easy to use, people will set it aside. When that happens, I notice that something is wrong and go back to refining.

Thankfully, in this case, the technicians have kept using the steps, so I think we’ve come up with a good solution. I’m pleased when I hear that it makes their work easier.

Turning painful experiences into creative ideas

Now let’s turn to idea number two.

This one can be found in another section of the Motomachi Plant, where back door wiring is installed. For some models, this process involves running various wires through the car’s interior. In the past, male employees had to contort their bodies into awkward positions to carry out the task.

This process was previously only needed for battery installation, but since the plant shifted to a high-mix line producing four powertrains—gasoline, HEV, FCEV, and BEV—work is also required inside the rear cargo area.

Having handled these duties, Hayato Ikeda was all too aware of the physical strain from his own experience.

“For electric vehicles (bZ4X, RZ) and models like the Noah and Voxy, you have to stoop down to install the rear wiring. That takes a toll on your back.”

Similarly, it was only certain models, such as the bZ4X and RX, that required workers to overreach on the instrument panel line, as we saw at the top of the article. Although the processes are different, both problems are unique to the Motomachi Plant and its mixed production line. They also both reflect the team’s eagerness to solve genba challenges with creative ideas.

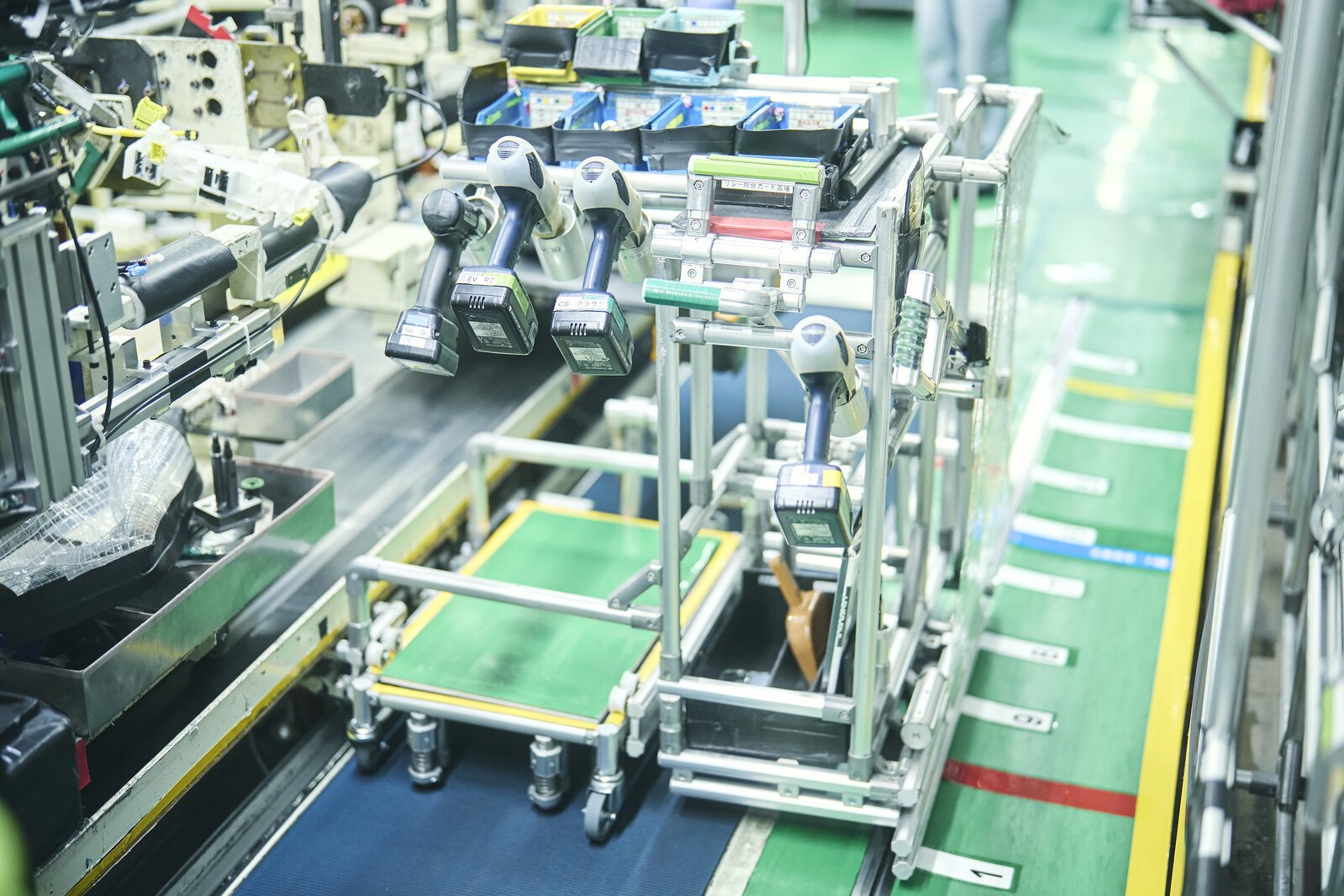

Ikeda led the way in designing an integrated “work seat” that slides seamlessly into the car’s cargo area and allows the job to be done from a seated position.

A combination of steps and seat, the device also provides space to store tools on the handle. The seat itself is adjustable, with springs in the base to ensure stability.

Joints are constructed with washers and rollers to prevent bending. The design can handle loads of around 100 kg, catering to different body types.

Hayato Ikeda

At first, we brought in some polystyrene foam to serve as steps and seats. However, this created not only a safety issue, but also debris when the foam was pierced or scratched by stud bolts inside the car.

We kept making improvements to arrive at the current form, integrating everything so that the seat could be set up in a single action. After all the hard work, there was an incredible sense of accomplishment.

From reward system to training tool

These two ideas share something else in common: the proposals were both entrusted to junior colleagues.

“As a team leader, pursuing improvements is not about the financial reward, but rather trying to instill the kaizen spirit in younger employees. The Creative Idea Suggestion System is an important tool in that regard. Simply writing the proposal is a learning experience, and ultimately, I hope this will develop our personnel.” (Yamashita)

“I knew this was an outstanding suggestion, which is why I wanted our junior members to submit the proposal. I hope it serves as a tool for them to make their mark within the company. Doing so would help them to grow and pave the way for the next generation. After all, our people are a precious asset.” (Ikeda)

As the two tell it, the Creative Idea Suggestion System’s appeal for employees is the chance to earn monetary rewards for improvements. These days, they also regard it as a tool for encouraging growth. That is why they entrusted their ideas to junior colleagues.

Finally, we asked what kaizen meant to each of them.

“Making difficult tasks easier to do. However, as the workers and car models change, new problems arise. In that sense, kaizen is a never-ending process.” (Yamashita)

“I think it is evolution. Kaizen is the way that things and processes evolve, and I want to ensure that they are constantly evolving and transforming.” (Ikeda)