Toyota's Creative Idea Suggestion System makes work more fun and interesting. This time, we showcase a karakuri contraption born out of the development genba for Toyota's moon rover, the Lunar Cruiser.

“We’re going to need a whole lot of twisted pair cables to develop and test the Lunar Cruiser.”

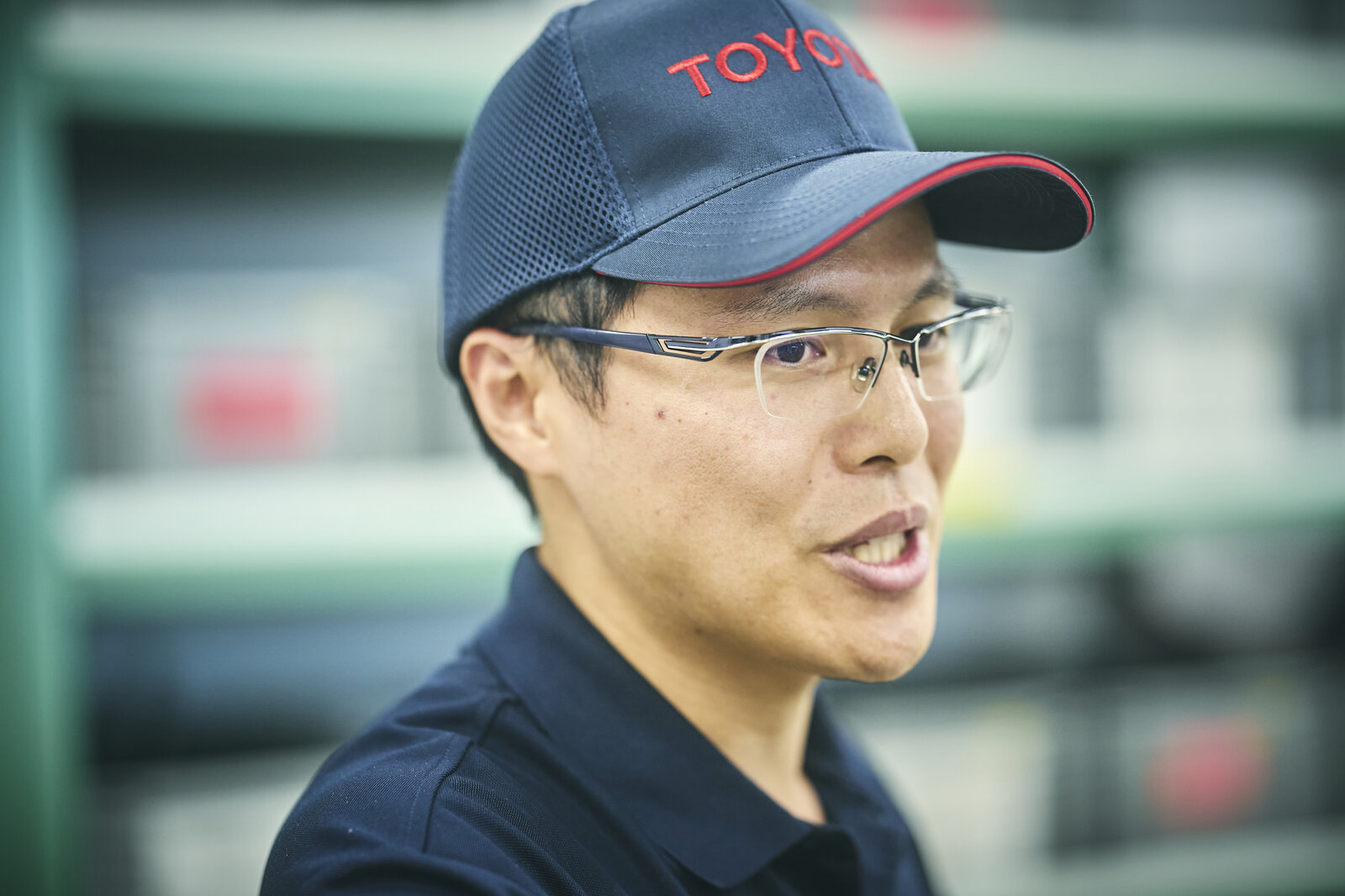

Jukiya Nobori was speaking to his colleagues at the Vehicle Engineering Development Division’s Chassis Component Testing Section. Anticipating the work that was to begin a year later, he wanted to begin creating the karakuri* that would make their jobs easier.

*Ways of automating and improving tasks without relying on electricity, by using simple mechanisms such as gears, springs, and levers.

As the name suggests, twisted pair cables consist of two wires intertwined together to reduce noise. In vehicles, they are mainly used for the CAN communication cables that send electronic control signals.

While Nobori’s team was developing the logic system for controlling the Lunar Cruiser’s steering, they realized that testing their work would require vast quantities of twisted pair cabling.

The tried-and-true method

Jukiya Nobori

I joined Toyota in 2012, and the way of making these cables hadn’t changed since well before my time. ① Cut two cables to the required length, ② clamp one end in a vise, ③ insert the other end into a hand drill, and ④ spin.

Twisted cables and specialized twisting machines were commercially available, but all the options were for bulk users. Since we only make the cables as and when we need them, that would have been overkill for our purposes.

The team uses cables ranging from one to five meters in length. Thirty rotations per meter is considered optimal twisting, but the work is done with eyeball estimates.

In the past, the cable could slip out as the hand drill turned, or the entire cable might get tangled up after being completed. Nobori says unraveling these cables was the most frustrating part of the task.

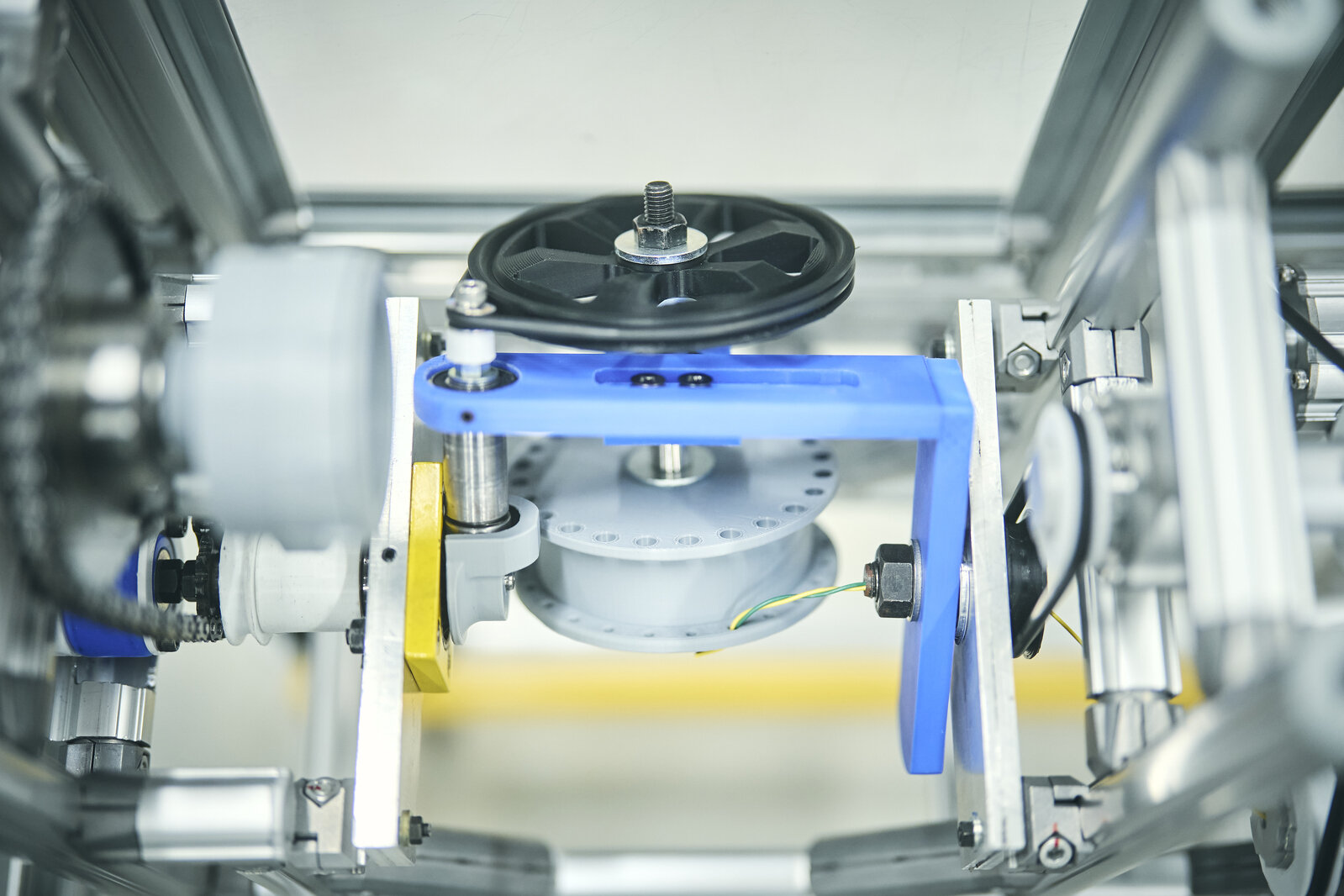

Twist machine jig simplifies a tedious task

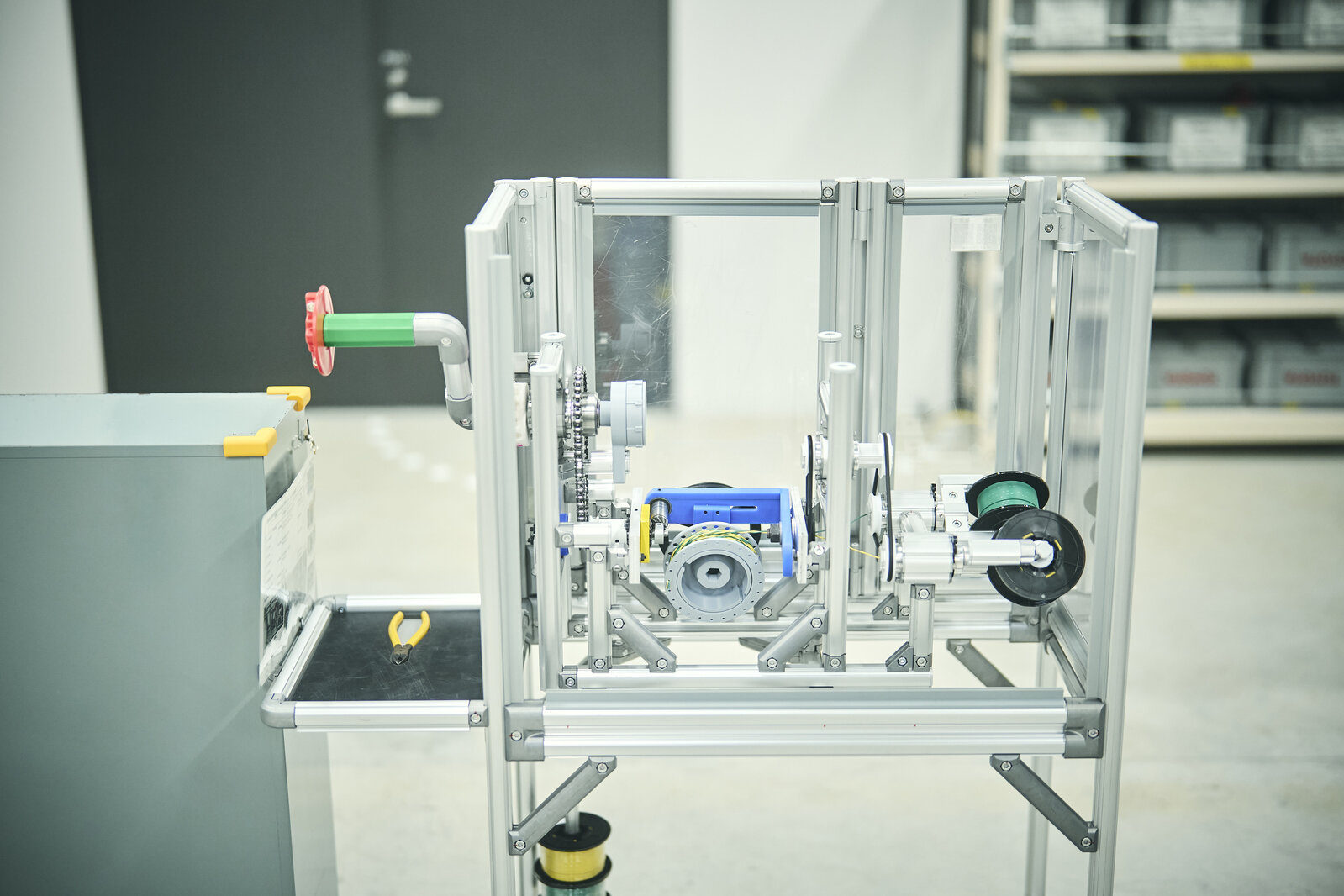

Let’s jump straight to the completed Twist Machine Jig.

The operation is simple: set two cable bobbins, then insert the cable ends into a hole in the side of the empty bobbin in the center. Then simply turn the handle to twist the cables together. Check the gauge markings, snip the cable once it reaches the desired length, and you’re done.

Jukiya Nobori

To begin development, the nine of us talked about what we wanted to do. The first thing that came up was making it compact.

With the conventional method, to make 5 meters of cable, you needed 5 meters of space. Sticking with a process that twists first and then spools requires space, which is why we shifted to a design that twists and spools simultaneously. We even used 3DCG*, which we weren’t experienced with, to simulate and test the motions.

*Computer software for constructing virtual three-dimensional spaces

The 3DCG software helped test an arrangement that uses bevel gears to make the bobbin rotate as it revolves. At the same time, a linked pulley turns to spool up the cable. Getting this far took the team about five months.

The next hurdle was twisting of a different kind. With one end fixed, the entire cord was becoming twisted under torsion. After a month or two of grappling with the problem, they hit on an idea: “What if we just made the fixed part turn as well?”

With safety also a priority, the team designed the jig so that it doesn’t work if the door is open, and a lever must be squeezed for the handle to turn. To prevent hands from getting caught, the mechanism requires a two-handed operation. This reflects the Toyota belief that “work starts with safety.”

For the base frame, the team used recycled aluminum tubing, while components such as gears and chains were sourced in-house. The counter with markings for measuring length was 3D printed. More surprisingly, the bevel gears were made by repurposing parts from a discarded grinder found at a recycling station. As a result, the total cost was kept to around 50,000 yen.

The jig took some eight months to complete. So far, around 300 meters of cabling have been produced for developing and testing the Lunar Cruiser, saving about 2.25 work hours per month.

Thanks to the twist machine jig, the team can quickly whip up more signal cables as needed during testing, keeping development running smoothly. As Nobori told us, this helps to ensure that testing will be completed within JAXA’s deadline.

Better than monetary rewards

This idea submission earned Nobori a 30,000-yen reward. And yet, there were many moments that brought him even greater joy.

“I was really pleased when people from other departments told us the mechanism was amazing, ‘on another level,’ and they wanted one for themselves. Also, the way our team members constantly gave each other positive feedback made development fun. It really energized the workplace.”

Creative ideas spark communication and convey feelings of gratitude. That’s where the system really shines.

Lastly, we asked Nobori what kaizen means to him.

“I think it’s about making people happy. When you make improvements that benefit others, their gratitude brings you joy. This drives you to keep making improvements, creating a cycle of smiles and joy. To me, that is the beauty of kaizen.”