Toyota's Kamigo Plant began operating with state-of-the-art facilities and weighty expectations. Today, what is the plant doing to ensure it will still be making engines a decade from now?

Making jobs easier with digitalization

“If the group leader boards were accessible via computer, you could instantly check progress anywhere, anytime,” says Teruo Miyanari, himself a group leader at Engine Casting Section No.1, in the Kamigo Plant’s Engine Casting Division.

He was speaking about digitizing the group leader management boards we introduced in our previous article on the plant’s history. At Kamigo, digitalization has even spread to the casting process.

The management boards are used to track each group’s progress in turning plant policies into genba objectives. In the past, group leaders would write out the daily figures and other information on paper. Not only was this task labor-intensive and time-consuming, but it also required storage space for the paperwork. “It was always exhausting,” says Miyanari.

Now, employees use tablets to input information such as the day’s parts inspection results, which are then consolidated on the management board. Even the graphs can be generated automatically. For group leaders, these changes have helped free up around 36 hours of additional work time per month.

In addition, the shift to digital systems makes it possible to notify team members instantly when defects occur.

Previously, the detection of casting defects and logging of related information was left to downstream processes after delivery, or the quality control department. Once a day, the casting team went to collect any defective parts that had been found. They would record the same defect information as the downstream processes.

In the casting genba, lead times between production and defect confirmation could be as long as five days, during which defective products might continue to pile up.

To improve this situation, the casting team worked with processing and quality control departments to create a general-purpose data entry tool that enabled real-time sharing of information. Details and location can be identified as soon as a defect occurs.

The shift to digital began around 2020. In the world of casting, operations often relied on the wisdom of veteran workers, but the adoption of digital tools has also encouraged junior staff to voice their opinions.

Miyanari and his team all agree on one thing: “Digitalization makes it easier for workers to do their jobs.”

Better conditions for women and older workers alike

The Kamigo Plant’s transformation goes beyond robots and digital solutions.

In the same spirit as the Super Skill (SS) Line introduced in our previous article, the Nijiiro (rainbow) Line initiative aims to create a workplace where diverse individuals can flourish.

This subline assembles cylinder heads for the G16 engine, which powers models such as the GR Corolla and GR Yaris.

With an eye on the future, various improvements are being made to accommodate older workers and women, offsetting any physical differences on the line. The team has established unique indicators by measuring aspects such as arm extension angles and distances. Parts and jigs are being made lighter and moved closer within reach to make tasks easier.

The Nijiiro Line began in 2018 at the Shimoyama Plant, which had adopted an integrated operating system for engine production since 2015, before moving to Kamigo last year. Currently, five women are working on the line, and the plant is working toward achieving active participation for all, together with even a more diverse group of employees.

“The groundwork has finally been laid,” says Expert Yuka Kawai of Engine Manufacturing Section No.21, part of the Kamigo Plant’s Engine Manufacturing Division 2.

Expert Kawai

In the past, the process dictated the personnel, excluding women from certain tasks. From now on, however, I think adapting processes to people is going to be crucial.

We want to put even greater focus on inclusion, aiming to create a line where every worker can fully exercise their individual traits and abilities.

*The handle held by Expert Kawai is another improvement example. This jig, used to tighten engine parts for models such as the GR Corolla, was formerly operated by grasping a trigger on the other side of the black grip in the top-left corner of the photo. However, this grip proved too thick for people with smaller hands, making it difficult to grasp the trigger at the same time; even those who could reach it may not be able to maintain the position, leading to irregular tightening. The solution was to install a handle nearer to the operator, with the blue grip linked to the jig’s trigger. It is easier to grasp, and also allows for two-handed operation.

These efforts are being undertaken by all of the section’s members. Manager Mitsuyuki Ichinohe acknowledges the challenges involved: “The question is, how many variations are we able to prepare for a single process? To accommodate diversity, the setup for each process needs to change whenever the people do, in order to suit that worker’s needs.”

At the same time, Ichinohe recognizes the positive changes, and the common thread that runs through kaizen efforts on the Nijiiro and SS lines: “These improvements are about caring for people, and they in turn put more care into their work.”

The seeds of diversity sown at Shimoyama are also bearing fruit at Kamigo.

Making your workplace more fulfilling

In November 2024, Toyota held one of its labor-management roundtables. As the discussion turned to the topic of lackluster workplace communication, Plant General Manager Saito made a comment along the following lines:

Plant General Manager Saito

I said, “Please provide us with break areas where everyone can relax and use their down time as they please.”

As we went about putting up wallpaper or renovating desks, these activities created sparks of communication, with an incredibly beneficial effect.

One thing that really caught our eye while visiting the Kamigo Plant was the distinctive character of the staff rooms and break spaces.

For example, the break area in the bottom left photo above had been set up using leftover wooden pallets, with tables and chairs made from scrap engine parts. They were dreamed up chiefly by the younger members of each section.

Notably, these break areas don’t have any of the work-related posters frequently seen around Toyota, such as those outlining the “seven types of waste.” Their absence reflects Plant General Manager Saito’s desire to create places where people can relax. “Work is tough, so staff should be able to enjoy their lunch breaks freely.”

The Moriage-tai is another youth-centered initiative that stimulates workplace communication. Launched at Shimoyama with the aim of reducing turnover among junior workers, the activities spread to the Kamigo Plant in 2024, focusing on getting staff excited to come in each day and making the job more enjoyable and fulfilling.

At the Kamigo Plant, the Moriage-tai has more than 40 members. Activities vary by section, ranging from baseball tournaments and volunteer community cleanups on days off to all-member kendama contests during break times.

It’s all about connecting with other people.

In the Kamigo Plant’s Engine Manufacturing Division 1, Shintaro Nakai (Engine Manufacturing Section No.11) and Team Leader Ryo Maruyama (Engine Manufacturing Section No.12) both belong to the Moriage-tai. They feel that the group’s activities are fostering better communication.

Nakai

While doing things together on our days off, I’ve learned more about the people around me. We’ve been inviting others in, and the group just keeps growing. I think ensuring young staff are not left on their own or isolated will have an impact on the turnover rate.

Team Leader Maruyama

When we decided to hold a Moriage-tai event, the team practiced during break times. I feel these activities enlivened the workplace by sparking conversation, whereas previously there had been little.

These efforts have created an environment where people communicate more, even on the job.

The initiative has only just gotten underway. While the actual contribution to retention rates remains to be seen, Plant General Manager Saito is optimistic. “I’m excited,” he says with a smile.

Setting sights on future automation

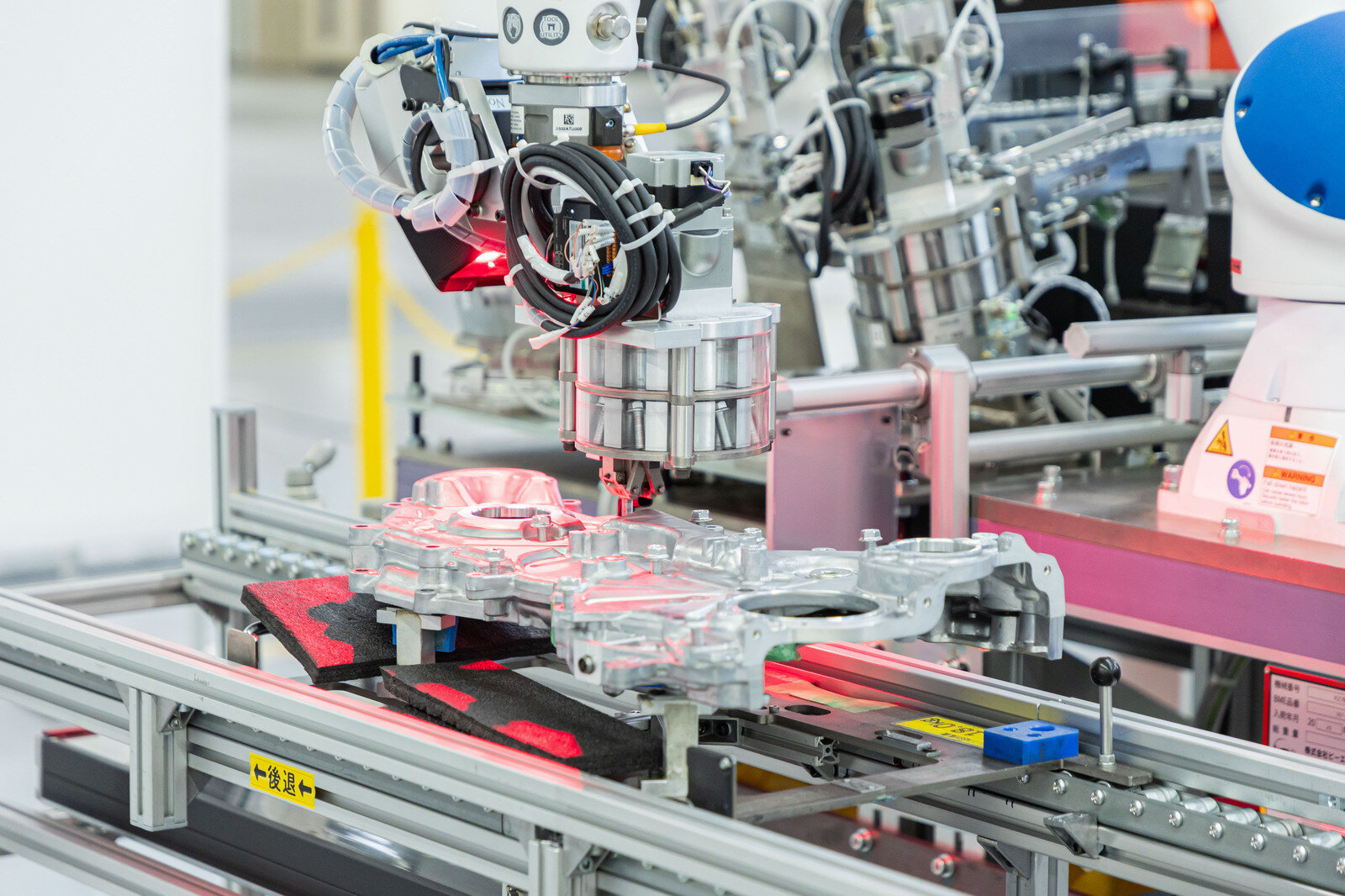

To wrap things up, let us turn our attention back to the production genba. In 2024, the Kamigo Plant launched its “Co-Creation Line” project.

The objective is to establish a line that harnesses current technical capabilities while offering a rewarding experience for future workers. At the same time, the plant is also looking to bring casting, machining, assembly, and even maintenance and quality control together from separate lines and buildings.

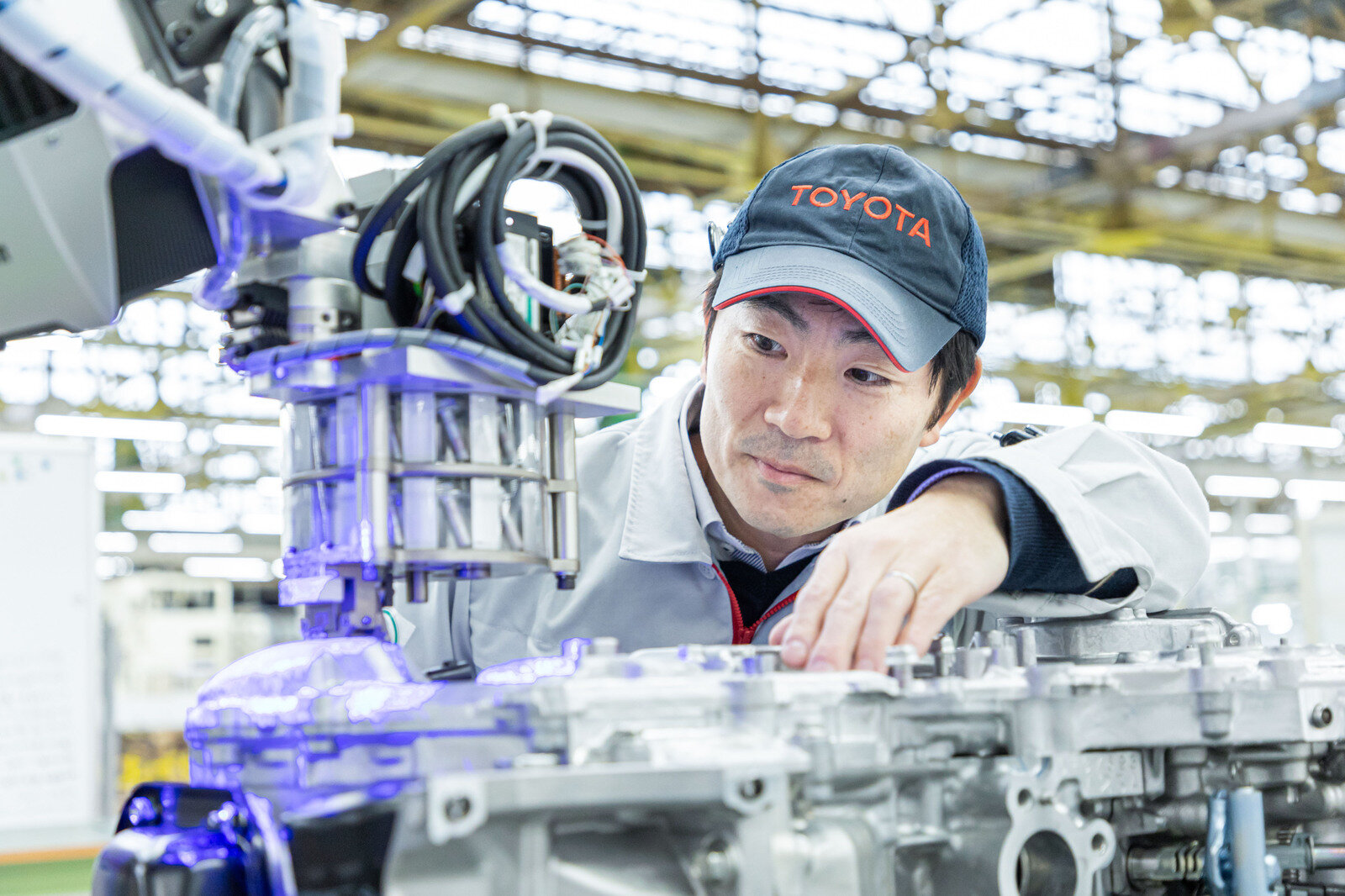

Kamigo is currently developing various technologies that will underpin future automation in engine manufacturing. The hope is that, with increased automation, workers can shift to tasks that add greater value.

These underlying technologies are refined on mass-production lines before being incorporated into the Co-Creation Line. The first automated machine created in this way will start out on the TNGA engine assembly line.

Masaya Gamo has been coordinating the development plans as a group manager in the Kamigo Plant/Shimoyama Plant Engine Manufacturing Engineering Division’s Project Innovation Department. He emphasizes listening to genba feedback and making items that can also function effectively on mass-production lines.

Group Manager Gamo

If the input comes solely from us engineers, we end up with only the technologies that we really want to develop. Instead, we considered what would truly make work fulfilling and figured out what we wanted to do from there.

The project involves a wide array of departments, from the various shops to assembly, machining, casting, maintenance, quality, and suppliers. We spoke with people in each one, asking what they found fulfilling and rewarding in their work, and then refined our development criteria.

Last year was devoted to working out the concept and speaking with genba staff to identify concerns and the factors behind job satisfaction. This year will be about deploying and testing items such as the aforementioned robot.

“The Co-Creation Line is a new challenge,” Gamo told us with a determined expression.