Our series showcasing Toyota's activities in non-automotive fields. Today, it's yakitori time!

This article is all about yakitori—more specifically, negima yakitori (grilled chicken skewers with scallions)! But what does that have to do with cars?

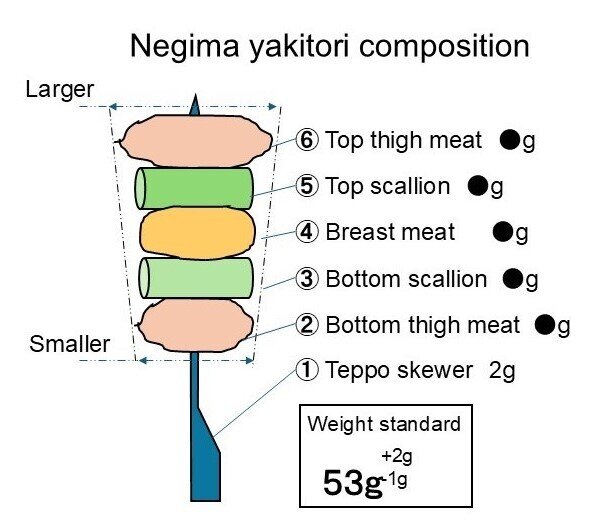

Let’s start with the following diagram. Who knew chicken skewers were made to such exacting standards?

The bottom pieces are smaller to ensure that even those close to the handle, which are more difficult to grill, cook evenly. Making the first mouthful of meat bigger is also meant to provide a more enjoyable texture.

It seemed like making cars and negima might actually have something in common… To uncover the truth, we visited Akitahinaiya, a producer of locally-bred Hinai chicken in Odate, Akita Prefecture.

We even got to sample another Akita specialty, kiritanpo (mashed rice on skewers). Or at least what we thought was kiritanpo… Read on to find out more.

A wall of complaints

In 2011, two weeks after the Great East Japan Earthquake, then-President Akio Toyoda visited the disaster-struck area and made a profound decision.

Recovery would take time, and the support had to be there for the long haul. Akio believed that the way to truly assist affected areas was to help manufacturing take permanent root in the Tohoku region.

This led to the birth of Toyota Motor East Japan (TMEJ) in 2012. The following year, TMEJ teamed up with local authorities to launch a new initiative, through which companies from different industries could learn about Toyota’s kaizen efforts and gain insights for themselves.

At present, 157 companies are involved, with Akita Prefecture’s Akitahinaiya among them.

Expecting a positive impact, the company’s leader says she was “shocked” by the results. What happened?

Yukimi Mutou, Representative Director, Akitahinaiya

We wanted a third party to come and see if we had been doing things right and tell us if there were any newer approaches we could take.

We have around 20 people working here, and the first step was to gather any concerns they had.

I didn’t think our employees would really raise any complaints, but it turned out they had plenty—64 in all! I was shocked there were so many (laughs).

Adopting the same method found at Toyota’s production plants, the submitted problems were posted up on a wall and taken down once resolved.

Despite her initial shock, Representative Director Mutou says she was pleased that everyone had spoken up to create a better workplace.

Starting with the storeroom

In tackling these genba issues, TMEJ’s kaizen team began with the storeroom. They explained their reasoning:

Yoshinari Kudou, Project General Manager, General Administration Division, Toyota Motor East Japan (TMEJ)

When you enter the genba in an unfamiliar industry, to get people on board you first need them to accept you. If we went in there telling them how to improve negima production, no one would listen. We began by getting our hands dirty and showing that we could solve problems through the 5S’s.

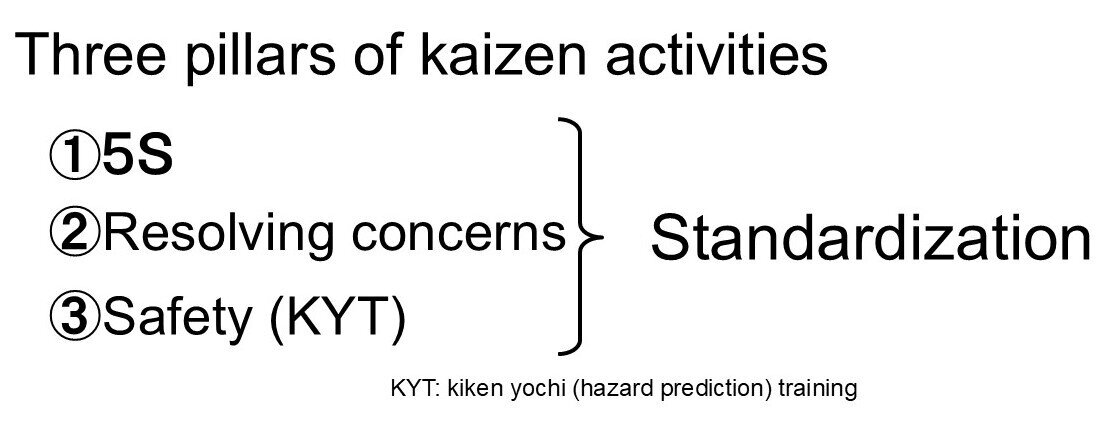

The first of our three kaizen pillars is the 5S’s: Sort, Set in Order, Shine, Standardize, and Sustain.

“We held on to things instead of throwing them away, but when the Toyota staff asked, ‘When do you use these?’ I didn’t have an answer,” says Representative Director Mutou with a wry smile.

The storeroom lacked a logical layout, with items used only in the December busy period given pride of place. Covered in sweat and dust, TMEJ’s team worked with Akitahinaiya employees to organize the space.

Their efforts cut down the time staff spend searching for items and made for a smoother workflow. Even Representative Director Mutou was impressed: “Look how much you got rid of—amazing!”

With that, it was time to tackle yakitori production. At first, the genba staff felt a little uneasy about being constantly monitored with a stopwatch.

And the result of these improvements? The time taken to make negima yakitori was slashed by 93%!

We could hardly believe our ears—93%?! That’s the power of kaizen… What’s more, many of the key points can be useful in all kinds of workplaces beyond manufacturing.