Our series showcasing Toyota's activities in non-automotive fields. Today, it's yakitori time!

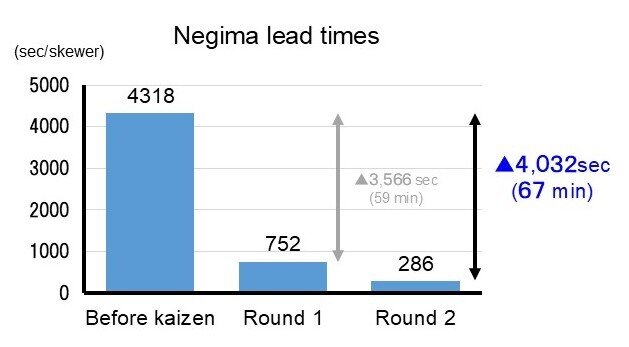

Before the kaizen efforts, staff took 4,318 seconds to prepare negima skewers. Now, they need only 286 seconds. How on earth did they manage such a massive improvement?

Tsuyoshi Chisaka, Senior Expert, Production Engineering Section, Toyota Motor East Japan (TMEJ)

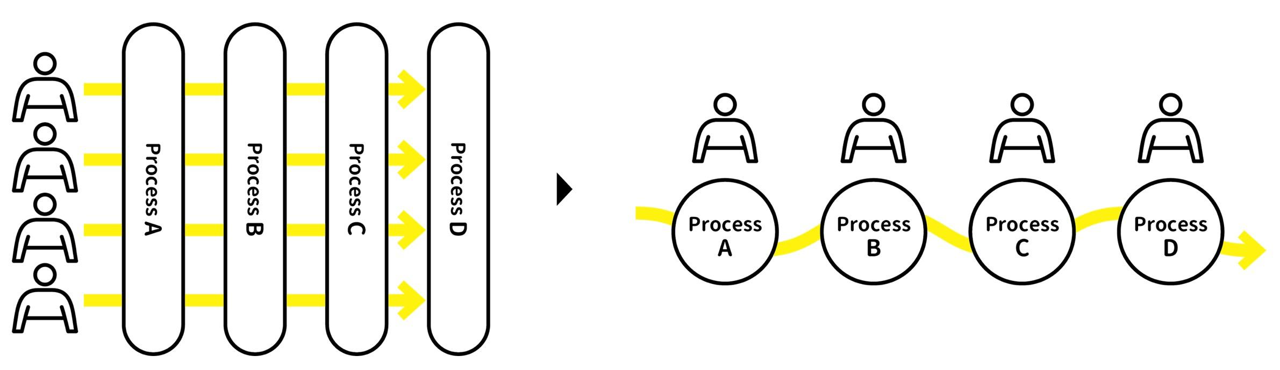

Before we made changes, one person did everything from cutting the meat to skewering, weighing, and arranging the trays. For the last step, they handed it off to the person in charge of vacuum packing.

But if you looked closely, this last stage created a bottleneck. There was also a lot of walking, with workers sometimes crossing paths. Our solution was to divide up the tasks. We tried shifting to an assembly line-style to ease the bottleneck while also raising quality.

Stopwatches in hand, the TMEJ staff examined how long each task required, and through trial and error reduced both the workload and lead time.

The improvements

Ingredients arranged by type

Previously, ingredients were laid out haphazardly, requiring more effort to find what you needed. Now they are arranged by type, cutting the time required to retrieve ingredients for one negima yakitori from ten seconds to three. The work area also looks much neater.

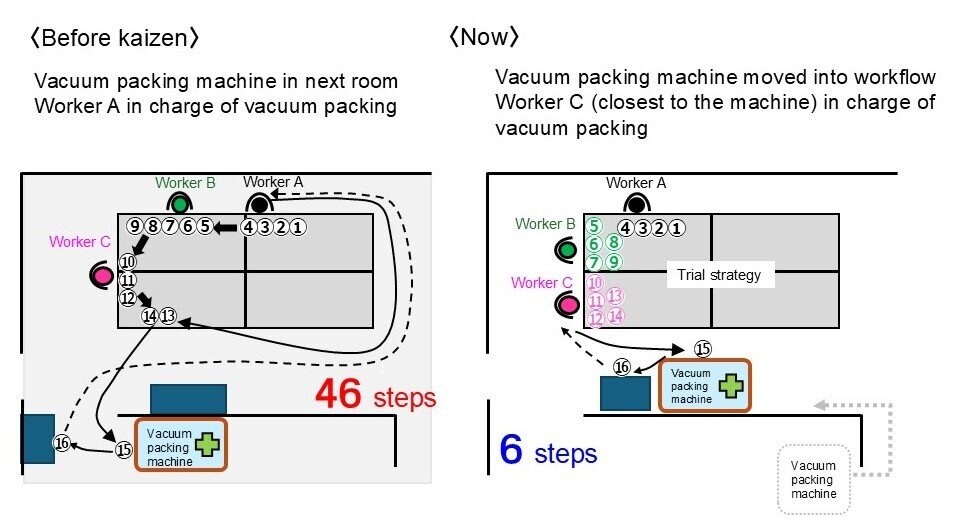

Layout changed to minimize walking

For the final packaging step, moving the machine closer to the workbench turned a 46-step trip into just six steps. The fact that staff no longer need to cross paths also makes work safer and easier. A simple layout change goes a long way in boosting efficiency.

Equipment placed closer to ease workload

Chicken broth is packaged by ladling the liquid from a large pot into a strainer. This physically demanding task could only be done by taller workers, but thanks to the addition of casters the pot can now be moved closer to hand. This idea was suggested by one of Akitahinaiya’s own employees.

Equipment heights adjusted to make work smoother and easier

Equipment that forced operators to stoop uncomfortably was raised higher off the ground, drastically easing the physical burden and helping prevent back pain for employees.

After the success of splitting up yakitori-making tasks, the same approach was adopted for sets of kiritanpo, a popular year-end gift.

Box-packing tasks also divided up, greatly reducing time

Thanks to layout changes, workers packing products into boxes can now stay in one spot, instead of moving around nine times as before. Clearly indicating the picking order and product names has also made work easier, shrinking the work required per box from six and a half minutes to two and a half.

Even during the busy season, the task no longer needs to be done in overtime hours.

A side note: as it turns out, the items pictured above, which people commonly think of as kiritanpo, are actually just called “tanpo” until they are cut up for use in hot pot dishes.

Let’s get back to the kaizen, which can also be found outside the building.

Parking lot paved to boost logistics efficiency

The site was once a nursery school, and initially the yard was left unpaved. With the region’s heavy snowfalls, however, the ground would turn to slush, hampering the dispatch of products. Paving the yard has improved transportation efficiency.

Kaizen has made work easier, while also boosting safety and efficiency. Half a year after TMEJ’s activities wrapped up, improvement ideas continue to emerge from the genba on their own. There is always room for more kaizen.

“It’s important to make people eager to get involved. After all, work is no fun when it is forced upon you,” says Kudou. During our visit, the employees’ smiles spoke for themselves.

At another project, however, the TMEJ team received a very different reaction: “What the heck would you Toyota guys know!”

Senior Expert Chisaka, Production Engineering Section, Toyota Motor East Japan (TMEJ)

Even at Akitahinaiya, at first we were addressed as “Toyota-san” rather than by our names. But gradually, they started calling me Chisaka, and I was really happy to be asked, “When are you coming next?”

It made me keen to do whatever was needed.

Being recognized and appreciated beyond Toyota is also good for developing future leaders in the carmaking genba. “Having spent our careers in carmaking, we have a great deal to learn by stepping outside the industry,” says Kudou.

An Akita Prefecture official also revealed the context behind encouraging local companies to adopt Toyota’s kaizen initiatives.

Ryohei Shimamiya, ACTIVE (Akita Center To Implement Vigorous Enterprises)

Akita’s population is declining faster than any other prefecture in Japan, so the challenge is figuring out how to make production more efficient with fewer people. With our aging population and the problem of business succession, we felt this was a good opportunity to raise productivity.

While bringing happiness to those working in the genba, Toyota employees also learned lessons from outside the company and, by helping make better quality yakitori, allowed more people to enjoy delicious products. This is what the kaizen-driven Toyota Production System is all about.