This series showcases Toyota's activities in non-automotive fields. In this installment, we look at how TPS is used in elementary school operations!

At this elementary school, it’s not the children but the teachers who are the ones in class!?

In recent years, the long working hours of schoolteachers have become a social issue in Japan. Seeking to improve working conditions, one elementary school in Fukuoka Prefecture turned to the Toyota Production System (TPS).

But do techniques honed through carmaking really carry over into the classroom?

Toyota puts teachers to the test

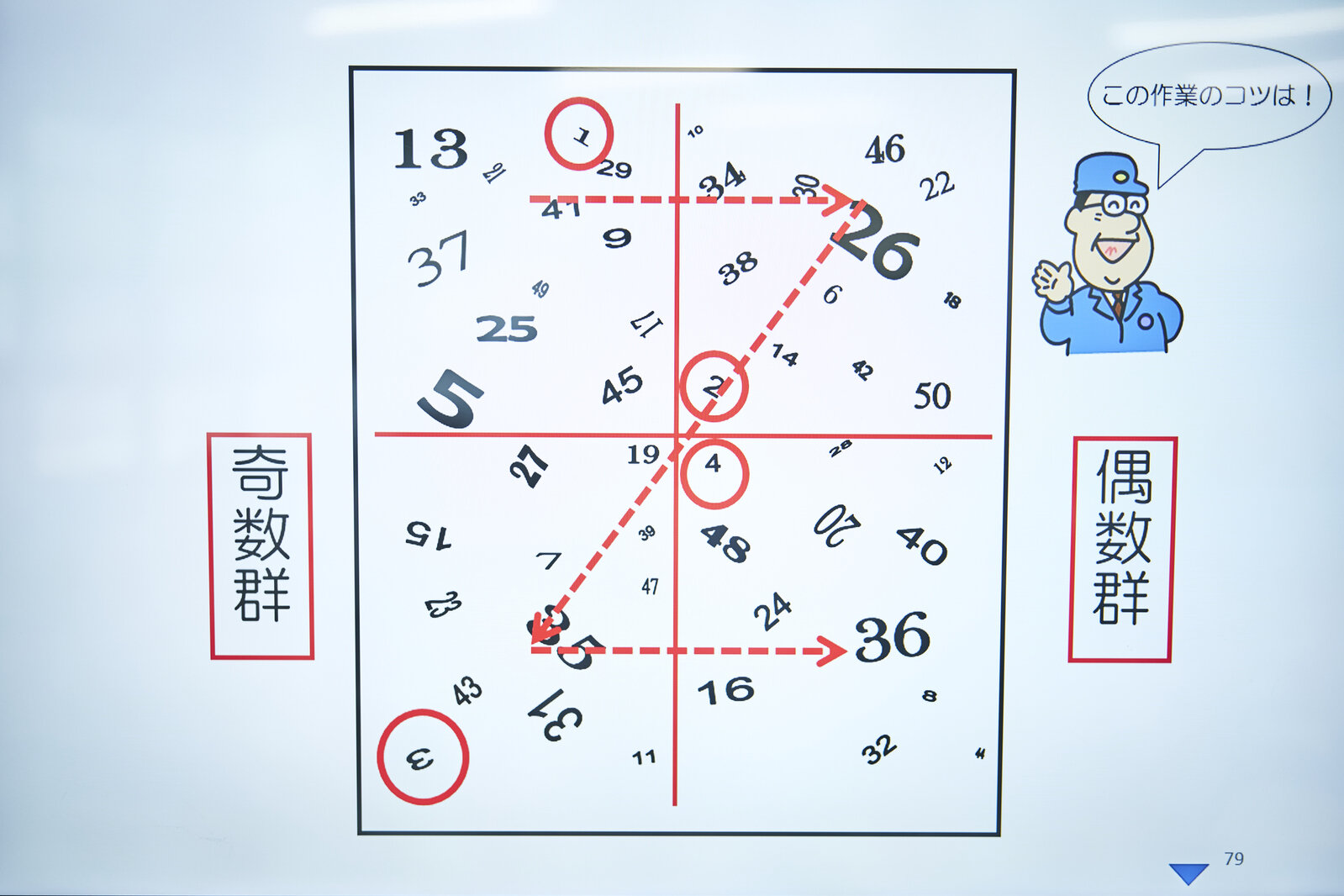

Here is a quick question for our readers: how long would it take you to count the numbers below, in ascending order?

This exercise trains you to find formulas that make the task easier. As soon as you notice the pattern (which we will reveal shortly), you can save a lot of time. The same idea applies to work.

Hiroshi Kumada, Project Manager, TPS Promotion Dept., Toyota Motor Kyushu

Teachers are inundated with countless tasks, from preparing events to handling finances. That’s why it is so important to learn the principles for eliminating waste and making work easier. By doing that, you free up more time to engage with the children.

And now for the answer.

If you divide the image into four quadrants, the numbers are distributed in sequence: top-left → top-right → bottom-left → bottom-right. Knowing this formula is a huge time-saver.

For this article, we visited Akama Nishi Elementary School in Munakata City, Fukuoka. Serving as a model school for work-style innovations, since last summer, Akama Nishi has welcomed a team from Toyota Motor Kyushu to help teachers put TPS into practice.

“We hoped to approach work reform from a different viewpoint by getting help from the private sector,” says Takuma Komori, a section chief at the Munakata City Board of Education.

“The city is making other efforts to reform operations, like outsourcing swimming lessons to private instructors, but we wanted an outside perspective to identify where the challenges lie and how to improve them.”

These sentiments were echoed by the school.

Fumika Kawakami, Vice-Principal, Akama Nishi Elementary School, Munakata

There is nothing wasteful in the educational genba. Or so I believed. But then, the advice we received from Toyota made me realize that, with a different perspective, you could find waste. I learned the importance of looking at things from a new angle.

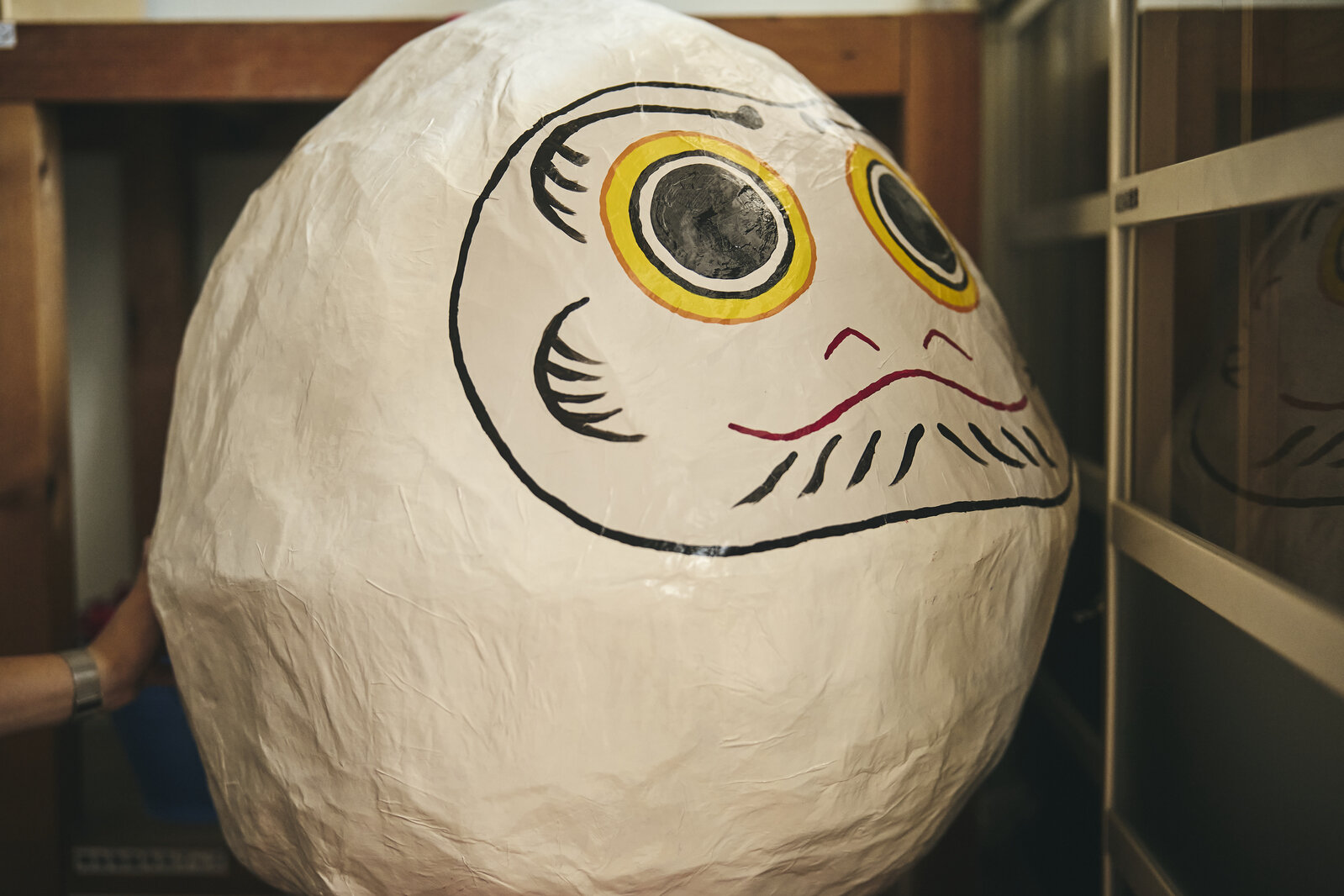

What to do?! The daruma dilemma

Staff from Toyota Motor Kyushu visit the school once a month. On the day we dropped by, the discussion centered around the use of the physical education storeroom. That’s where we encountered the daruma dilemma…

This giant daruma and its red twin are only brought out for the annual sports festival. And yet, in the overflowing PE storeroom, there was no space to put it except right by the door… As a result, more frequently used equipment was harder to access.

Shigehiro Sasaki, Senior Expert, TPS Promotion Dept., Toyota Motor Kyushu

We suggested moving it to the outdoor storage shed, but the teachers objected. This special daruma had been made by people in the community, and they didn’t want to put it outside where it was more likely to get damaged.

After some discussion, the teachers decided to reorganize the storeroom and find a place for the daruma. We were simply there to give suggestions, and the teachers made the decisions.

To be effective, kaizen must be ongoing.

That is why Toyota’s stance is merely to provide suggestions and advice, allowing the kaizen mindset to take root within the school. Essentially, the company is there to help lay the foundations.

And so, the big storeroom cleanup got underway. The red and white daruma twins sat waiting in the hallway, looking somewhat doubtful that the space would actually materialize.

When we asked about items that turned up during cleaning, in some cases even the teachers struggled to explain their purpose… It was up to them to decide whether these things were really necessary and to find appropriate spots.

With the cleaning done, enough space was freed up at the back of the storeroom. Problem solved! Not only was the room tidy, but it also became easier to use.

The teachers had felt too busy to find time for organizing. Yet being busy is precisely why they needed rules and designated places for items, which enable everyone to save time.

On the next page, we share many tips that could be useful in any workplace. Why not give them a try?