This series showcases Toyota's activities in non-automotive fields. In this installment, we look at how TPS is used in elementary school operations!

The kaizen keeps coming!

Over the past year since last summer, the school has put TPS into practice in all kinds of areas. Here are four major examples:

Case 1: Organizing cables in the broadcast room

Before

All kinds of cables were kept together, and only the supervising teachers knew what each was for.

▼

After

The location and purpose of each cable are clearly labeled and easily understood by anyone.

Colored paper makes the differences between cables obvious at a glance, saving a great deal of time both in searching and putting away.

Case 2: Ensuring that broadcast room items have a set place

Before

Everything was placed randomly, meaning items took time to find, and no one noticed when they went missing.

▼

After

With set places for everything, no time is wasted on searching. Plus, the room looks nice and tidy.

Case 3: Batching financial tasks for greater efficiency

Before

Each teacher took care of the finances for their own class, requiring them to stay late after school.

▼

After

One teacher is assigned to handle finances for each grade, reducing the workload for everyone else.

Unlike companies, schools often lack dedicated staff for tasks such as accounting or general administration. Evenings after class were often spent on meetings and administrative tasks, inevitably extending the workday.

Case 4: Visual system for keeping track of keys

Before

No way of knowing who had taken the keys to each classroom.

▼

After

When taking a key, teachers stick a magnet in its place, clearly marking who is using it.

The key-tracking idea was something the teachers came up with on their own—clear evidence that kaizen is taking root.

Why are we doing this?

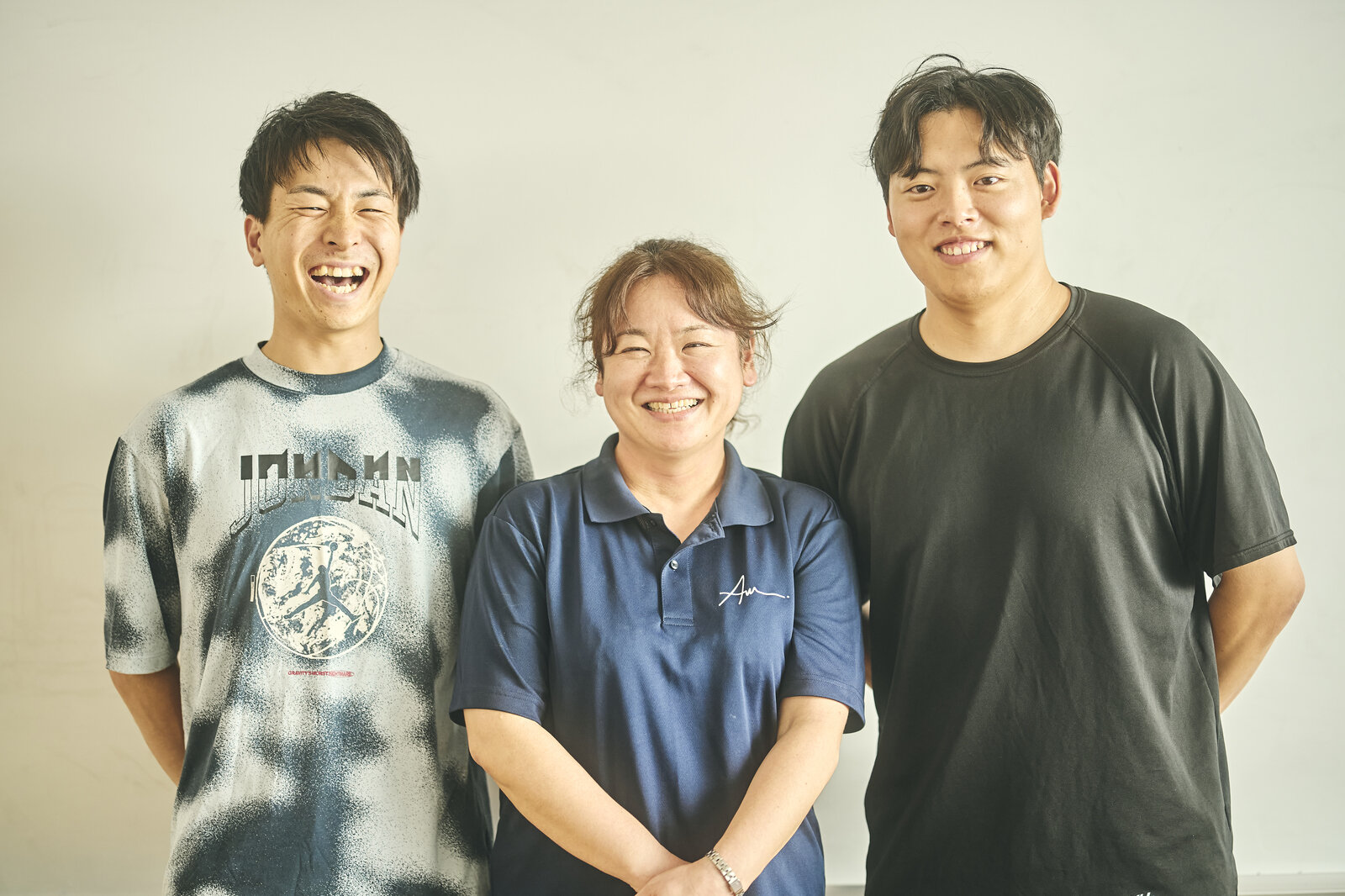

We asked the teachers to share their honest opinions of these TPS efforts.

At first I was not happy. “Why are we bothering with this when we’re so busy?” (laughs)

But then I realized how much easier work becomes when even new teachers can instantly see where everything goes.

Sometimes it felt like a real hassle (laughs). But once you actually get going, it really does save time, and I’m sincerely glad that we did it.

The initiative was not fully appreciated from the outset. Even the Toyota staff could see that.

Atsuo Wakuda, Project Manager, TPS Promotion Dept., Toyota Motor Kyushu

Initially there was this feeling of, “Why should we listen to these guys who know nothing about working in a school?” That’s why we listened to what they had to say about the challenges they faced rather than imposing our way of doing things.

The teachers were not really conscious of the long hours they worked. We wanted to send the message that they could make their lives easier. We want to help them get there by continuing to make small improvements.

At Toyota, what’s important is not merely reducing waste, but also the spirit of working for others. For the school’s principal, this came as a surprise.

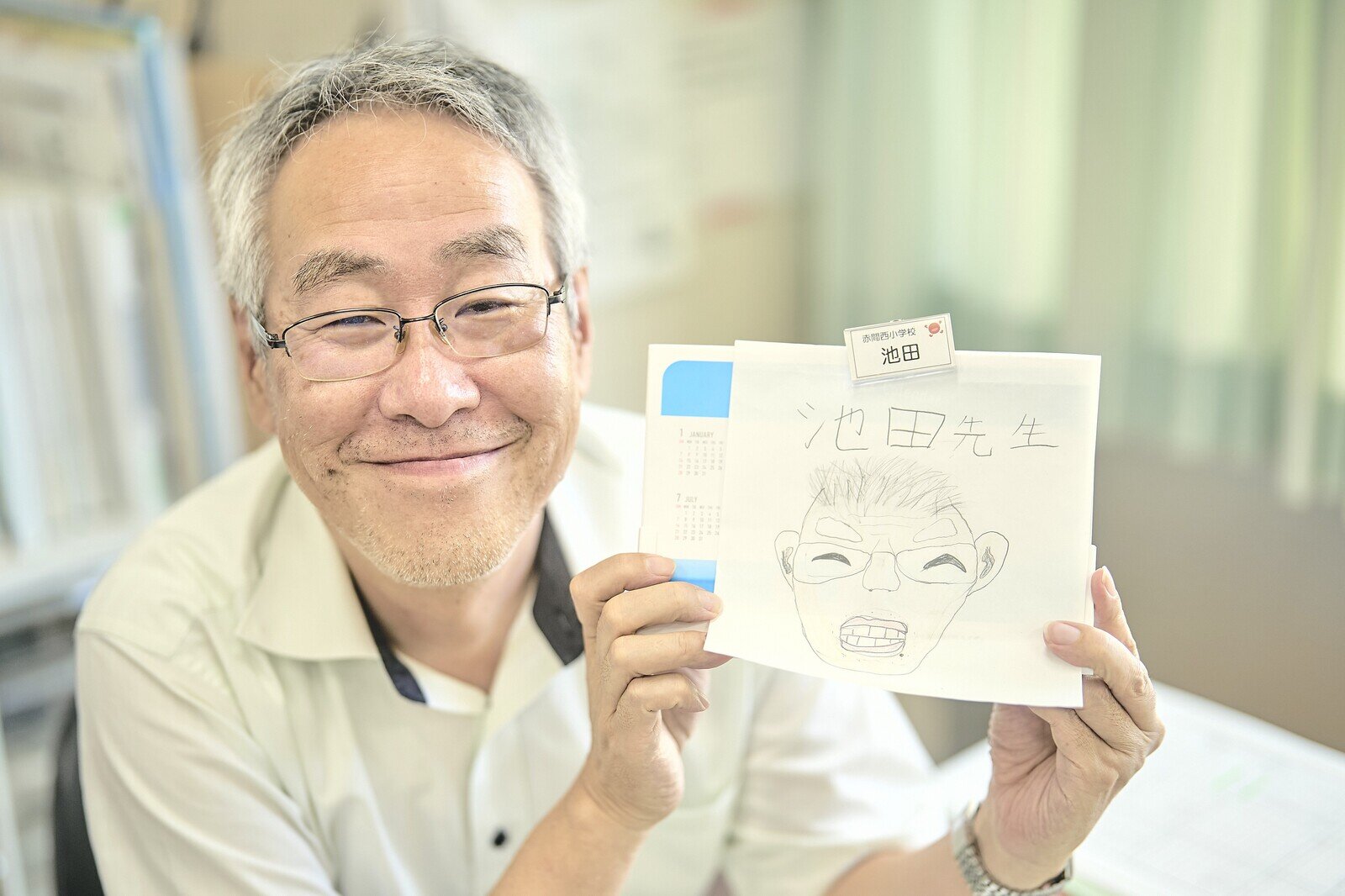

Shigeru Takahashi, Principal, Akama Nishi Elementary School, Munakata

I expected the Toyota staff to come in looking to eliminate waste, but I was surprised when they asked, “What kind of school do you want to create?” and “What kind of teachers do you want to be?”

In our case, Toyota’s philosophy of working “for others” can be rephrased as “for the children” and “for the teachers themselves.” I saw how this mindset can be applied anywhere.

Being a teacher is like running a one-man business. Each individual has their own way of doing things. In such an environment, establishing common rules to eliminate waste makes everyone’s job easier.

The Toyota Production System is often misunderstood as being purely about efficiency. Make sure to read our past article, “Akio Toyoda’s View on Toyota Production System,” in which he shares his personal perspective.

Munakata City is set to begin introducing TPS initiatives at other elementary schools as well. What’s more, the teachers who experienced TPS firsthand at Akama Nishi will someday transfer to other schools, helping spread these ideas to new places.

The way schools operate may not undergo a dramatic transformation. But as more people approach their work with a TPS mentality, the future is sure to look different.