An ongoing series looking at the master artisans supporting the automotive industry. For our 20th installment, we spoke with the mold-polishing master whose mirror-like finishes produced Toyota's first paintless bumpers.

Handwork still plays an important role in today’s car manufacturing, even as technology like AI and 3D printing offer more advanced methods. This series features the craftsmanship of Japanese monozukuri (making things) through interviews with Toyota’s carmaking masters.

This is the second part of our article showcasing the Mobility Tooling Division’s Hideki Kato, who produces plastic part molds with mirror-like finishes. His dedication to his polishing skills lies behind the Crown Sport’s paintless rear lower bumpers.

#20 Hideki Kato, a master mold polisher who creates flawless mirror finishes by hand

Senior Expert, Mobility Tooling Division, Toyota Motor Corporation Production Engineering Development Center

Starting from scratch

In part one we introduced Hideki Kato, a master mold polisher with four decades of experience, and his challenge of creating a paintless bumper. Here, we trace the specific steps he took on his path to success.

Kato and his pupil, Chihiro Takeshita, started entirely from scratch, which meant figuring out what tools and processes could polish molds to a mirror finish.

Kato

Since this had never been tried before, we went through a lot of trial and error to find a suitable method. Over the course of about a year, during downtime in our regular work, we tested out different types of abrasive stones, sandpaper, and abrasives, searching for the best polishing method.

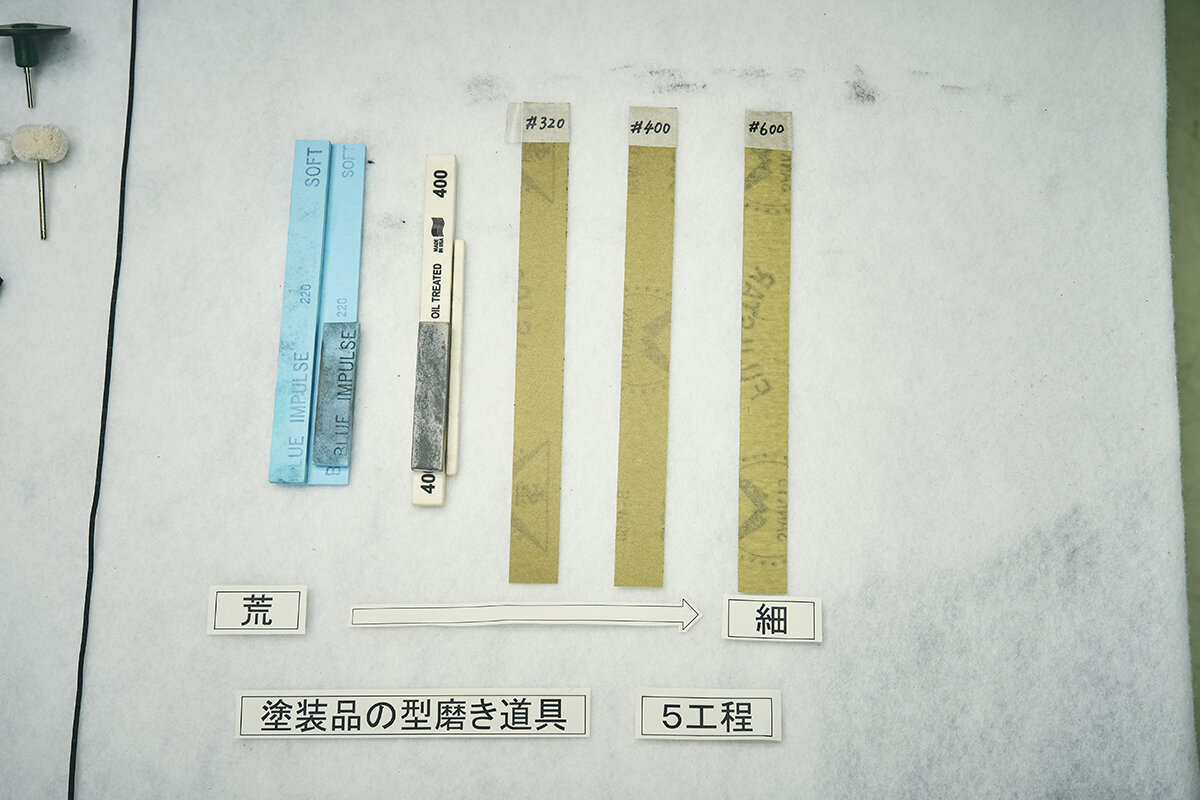

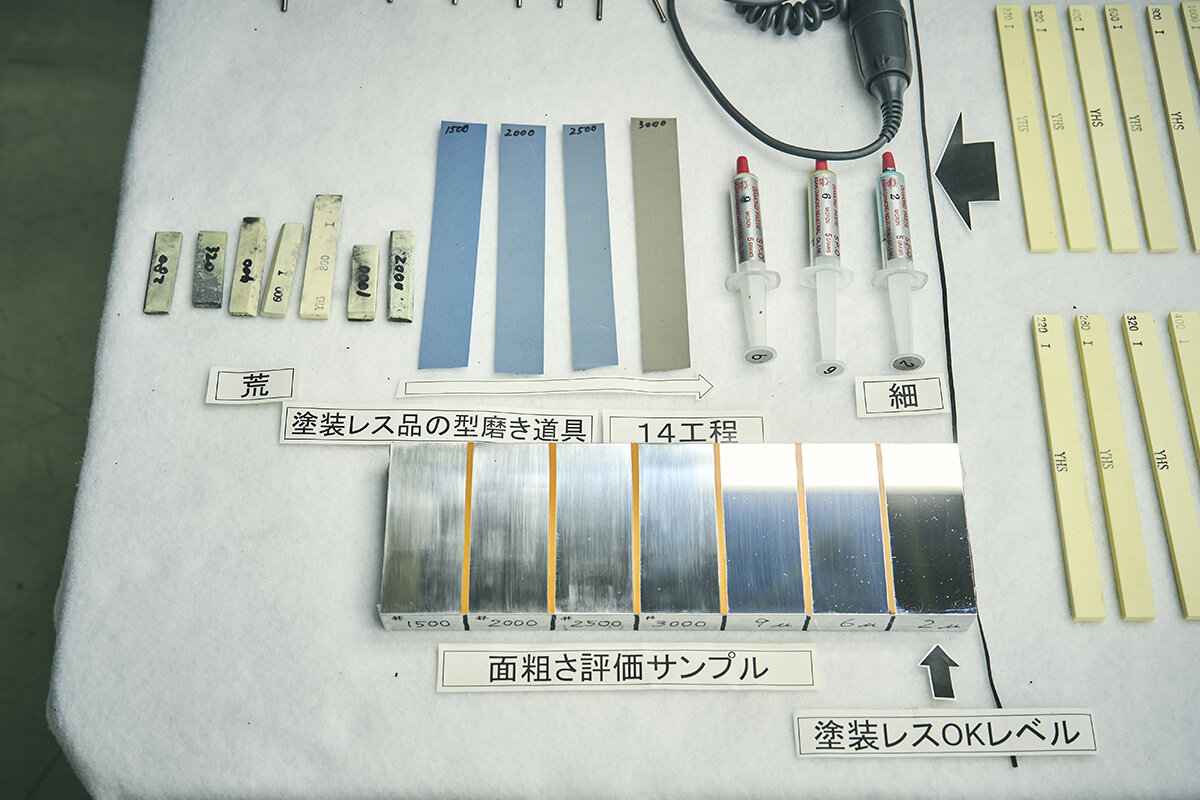

Molds for regular painted parts are completed in five stages of polishing, using five types of abrasive stones and sandpaper. By contrast, Kato found that achieving the mirror finish for a paintless part mold ultimately required 14 stages, using seven different abrasive stones, four grades of sandpaper, and three types of diamond paste for polishing.

Even after settling on the tools and process, the problems continued. After some six months of trial and error, the pair discovered countless small holes in the machined mold, indicating an issue with the material itself.

Kato

Around the time our polishing techniques and processes were mostly finalized, we noticed that many tiny pores had formed on the surface of the mold. They were caused by microscopic particles detaching from the material’s structure, but no matter what we tried, we couldn’t get rid of them. We ran into this problem at a stage where we had largely figured out the tools and steps, and suddenly the whole project was in jeopardy. It felt like six months of work had been undone in an instant.

Takeshita

Facing that problem felt like we had really hit a formidable hurdle. I was afraid that the process we had worked so hard to establish would no longer be of any use.

Holes such as these stem from the way in which the mold material is made. When high-temperature metal is compressed during forging, trace amounts of foreign matter, such as nitrogen from the air, become trapped and harden as iron nitrides. While these don’t normally pose much of a problem, when you polish to the level of a mirror finish, they flake off, leaving behind holes.

To solve this problem, Kato and his colleagues learned that they would need a harder steel with fewer impurities. Tsubasa Nitta, the Production Realization & Production Engineering Division member who initiated the paintless bumper project, set about trying to find a new material.

A specialty steel forged in a vacuum environment was an ideal choice, containing few impurities, but sourcing a block large enough for a bumper mold proved difficult in Japan. Nitta investigated various avenues before finally tracking down a suitably sized piece of steel overseas.

Nitta

We couldn’t find material of the right size in Japan, so I researched steel manufacturers in various countries. The steel I eventually found enabled Kato to accurately translate his exceptional skills onto the mold.

Mirror polish and lacquer-black beauty

Having secured the proper material, Kato and Takeshita once more got to work on polishing the rear lower bumper mold—a task that would take them around 800 hours in total.

Kato

The most time-consuming part is the initial surface preparation with the abrasive stones. If this step is done poorly, you won’t achieve the ideal finish, no matter how thoroughly you polish later on. We spent more than half of our overall time on this fundamental surface preparation.

With the polishing work stretching out to 800 hours, the physical toll became a major issue. In particular, holding abrasive stones while polishing places a heavy strain on the fingers and wrist.

Takeshita

Over a long stint of polishing, gripping the stone with your fingers becomes more and more painful, and you struggle to apply pressure. To solve this, we developed a holder for easy gripping. We couldn’t find any off-the-shelf product with the ideal angle, so I prepared the 3D data and made one on our 3D printer.

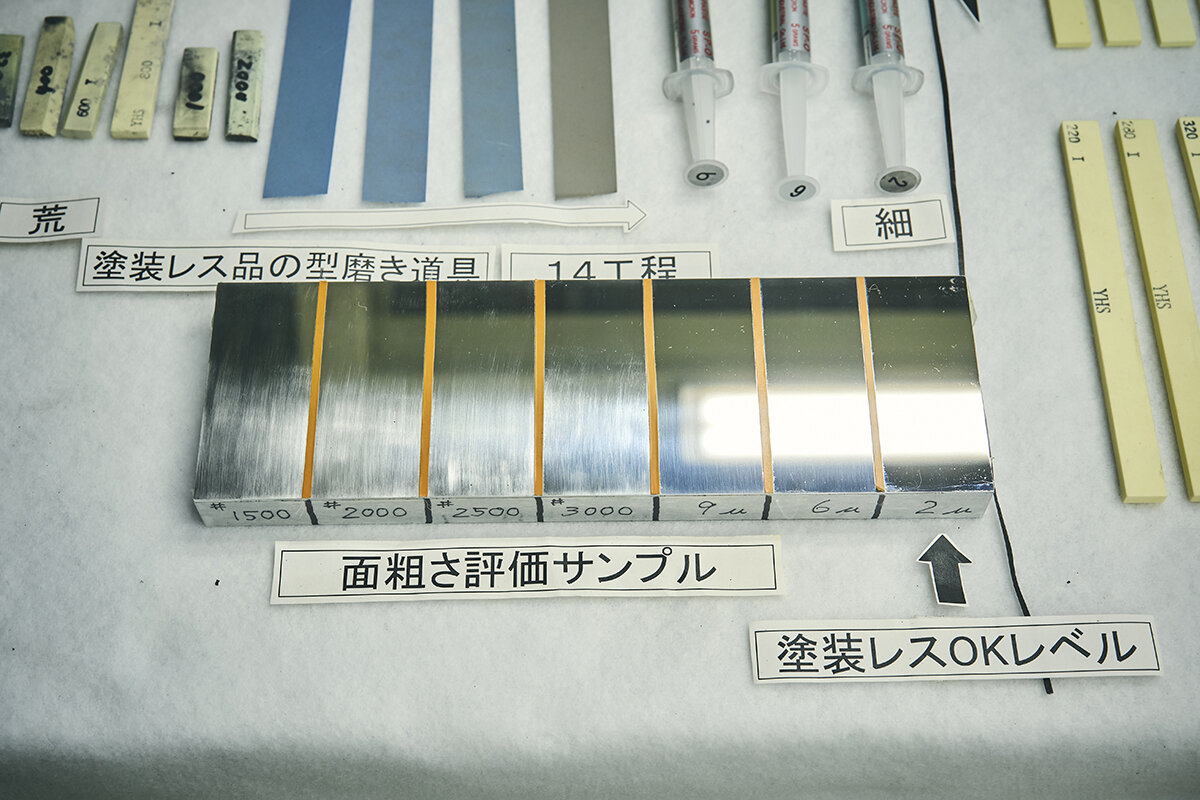

New issues specific to creating a mirror finish also came to the fore. Subtle inconsistencies in the polishing, which would not be noticeable in regular painted parts, affect how light is reflected by the mirror finish. Particularly, in order to improve the “L-value” (an indicator used for shades of color, with lower numbers denoting a deeper black) of paintless plastic parts, the mold’s surface needed to be as smooth and even as possible.

Kato

With a mirror polish, even surfaces that appear perfectly flat may actually be slightly uneven. When polishing with sandpaper, on a painted part you can just rub away without giving it much thought, but a mirror finish requires a delicate touch, uniformly applying the same pressure. If pressure is applied inconsistently, you end up with slight unevenness in the surface, which impacts the L-value of plastic parts.

Kato says that the first rear lower bumper to come out of the mold failed to reach the target L-value.

Kato

We polished the mold until we felt it would do the job, but the resulting part was deemed not black enough. When polishing a mirror surface, minute blemishes in the initial stages carry through and affect later work. To achieve a higher quality finish, you need to go back to that first stage. We did that four times. On top of that, after sandpapering we used a felt disc for the finishing touches to remove any fine marks. With the felt disc, we were careful to polish with a uniform pressure to minimize scuffing as it rotated, and lastly, we hand-polished with cotton. By repeatedly revising our process in this way, we eventually managed to reach the target L-value.

The paintless bumper is born

After multiple cycles of trial and error, the paintless rear lower bumper finally got the green light, three months before the Crown Sport went into production.

This feat was not accomplished solely through the skills of Kato and Takeshita, but also through their collaboration with many other technicians, including Nitta, who tracked down the most suitable material, and Toshihiko Toyoda, the Mobility Tooling Division engineer responsible for designing the mold.

To produce a glossy look, the paintless bumper’s resin has to be harder than the standard material and does not flow as readily. Toshihiko Toyoda increased the number of inlets to ensure that the plastic could spread to every corner of the mold and also devised ways to vent the gases emitted in the process.

Katsuyoshi Shimakata, Kato’s supervisor at the Mobility Tooling Division, emphasizes the benefits of paintless parts, which go beyond reducing environmental impact.

Shimakata

Firstly, they look beautiful. You don’t get the slight inconsistencies and grainy “orange peel” texture that inevitably comes with painting, so the light reflects naturally for a smooth appearance. Another big advantage of paintless parts is that they are easier to repair. If a regular part is damaged, you need to strip the paint around the affected area and then repaint it. With paintless parts, however, the material itself is colored, so all it takes is some polishing to restore the damaged section to its original state. The fact that they can be easily repaired with store-bought compounds is a key difference.

The next mission

Today, Kato is focused on sharing his skills with younger generations.

Kato

I feel that I have a vital mission to pass on these skills. Each skilled craftsperson I can train in this field will mean more high-quality products going out into the world. Working with our limited personnel, there is only so much we can do—but if we increase the number of people who possess these skills, we can contribute more broadly to product development.

At present, Toyota’s cohort of craftspeople who can produce a mirror finish has risen to five, and Kato is aiming to add about two more.

Takeshita is also working to make the skills transfer more efficient with videos that capture the master’s techniques.

Takeshita

The challenge in passing on this level of craftsmanship is that words alone struggle to convey the subtle nuances. To get around this problem, I filmed the work being performed and created video lectures, adding commentary on the key points for each step. They enable young technicians to visualize tasks before getting stuck, helping them learn the skills more efficiently.

The paintless technology that came to fruition with the Crown Sport’s rear lower bumper is expected to become more widespread. Although currently limited to black parts, the team is planning to attempt white components in the future.

Even in this age of technological progress, the skills and senses that Kato has honed over his 40-year career—one dedicated entirely to crafting molds—have a value that machines cannot replace. Through a single bumper, these finely tuned skills have helped to make car manufacturing more environmentally friendly. Kato’s story serves as a prime example of how craftsmanship is becoming increasingly important for automakers in the carbon-neutral era. His skill and passion for fostering the next generation will no doubt continue to shape our mobility future behind the scenes.