Toyota's liquid hydrogen-fueled Corolla took on the Fuji 24-hour race for its third year. The car is moving ever closer to commercialization.

This year’s focus: technologies for commercialization & mass production

Making up for last year was not the team’s only concern ahead of this season’s Fuji 24-hour race.

GAZOO Racing President Tomoya Takahashi reflected on Toyota’s hydrogen endeavors to date, while outlining the key themes for this year’s race.

President Takahashi

If we include our efforts with gaseous hydrogen, this year marks our fifth season racing in Super Taikyu with hydrogen engines.

However, the underlying research into hydrogen engines began about five years earlier.

The combustion of hydrogen posed us the greatest difficulties, but we have now reached the stage where we can complete a 24-hour race without major problems. I think we’re gaining a good command of the fuel.

The ultimate goal of these efforts over the past decade is to bring the results to market, so the focus this time was to improve the technologies for commercialization and mass production.

To pave the way for commercialization and mass production, the team took on three new technical challenges.

Toward commercialization 1: Variable combustion for power & efficiency

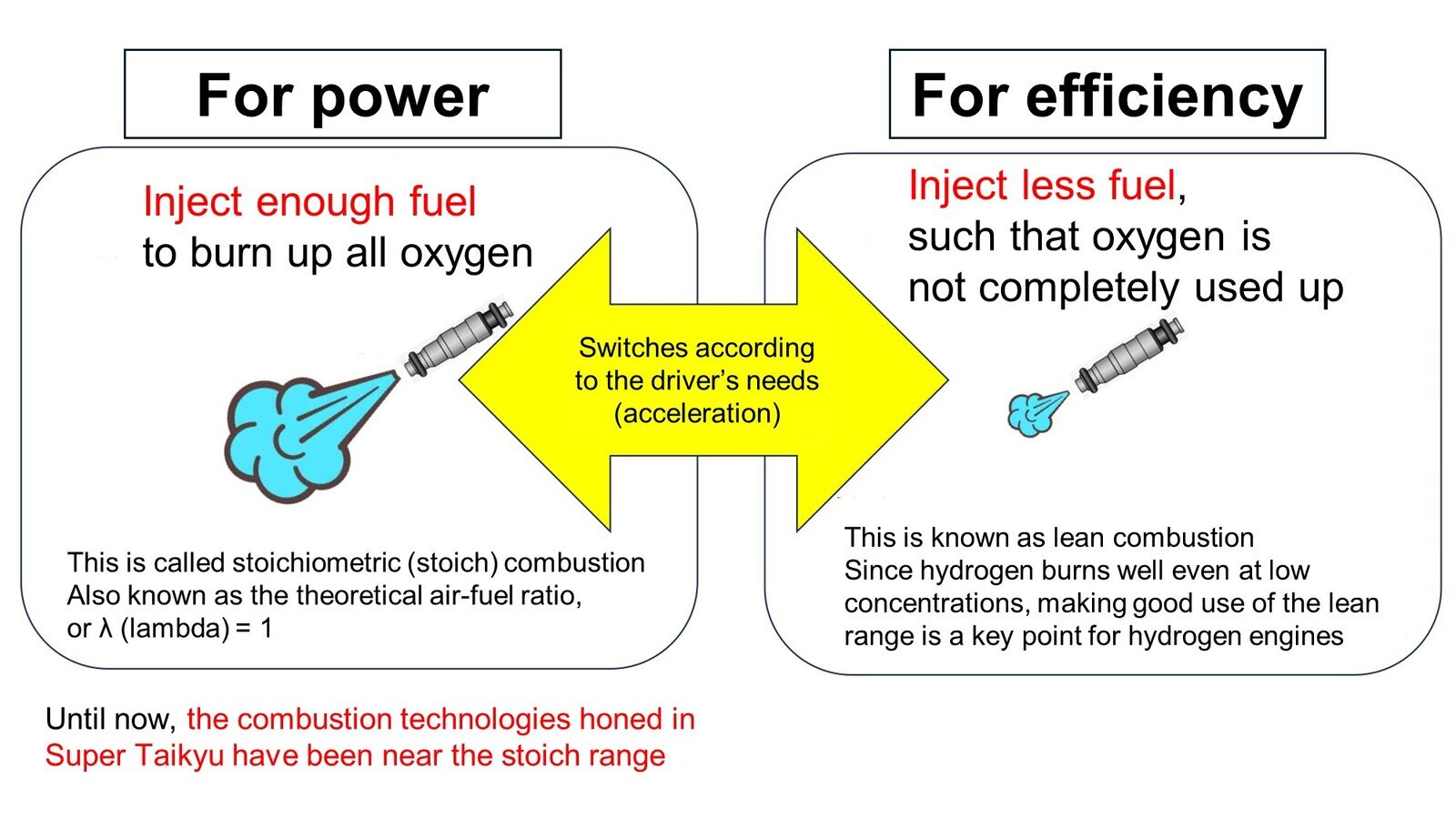

The first was a technology that automatically switches the combustion mode based on how the driver accelerates.

To achieve race performance on par with gasoline, the team has thus far continued to refine technologies for stoichiometric combustion, which delivers more power.

Creating a product for the mass market, however, will require better fuel efficiency.

That is why at Super Taikyu, Toyota began testing a technology that automatically switches to lean combustion, which enables more fuel-efficient driving, whenever high output is not needed.

Unfortunately, for the most part, a racing environment requires high-power stoichiometric combustion, which made the fuel efficiency benefits of the lean mode hard to assess in the 24-hour race. For now, engineers focused on seeing whether the system could reliably switch to lean combustion as necessary, even in a race setting.

They found that when high output was not needed, such as when speed restrictions were put in place due to poor weather or incidents on the course, the system appropriately switched to lean combustion without feeling awkward for the driver.

Project General Manager Ito was pleased with the results, saying, “We managed to get a great deal of data that we are eager to take home and analyze, so for a first try I think it went well.”