Toyota's liquid hydrogen-fueled Corolla took on the Fuji 24-hour race for its third year. The car is moving ever closer to commercialization.

Toward commercialization 3: Aluminum wiring harnesses reduce vehicle weight

Finally, another indispensable element in Toyota’s push toward commercialization: reducing vehicle weight.

One such reduction was accomplished by changing some of the wiring harnesses that supply electricity and transmit signals from conventional copper wire to aluminum.

This change cut the weight down by 18%. However, since racing cars such as the liquid hydrogen Corolla only use the bare minimum of wiring needed to run, a much bigger impact is expected in production models fitted with navigation systems and various other devices.

Typically, the downside of using aluminum wiring harnesses is the issue of corrosion, caused by water getting on the terminals.

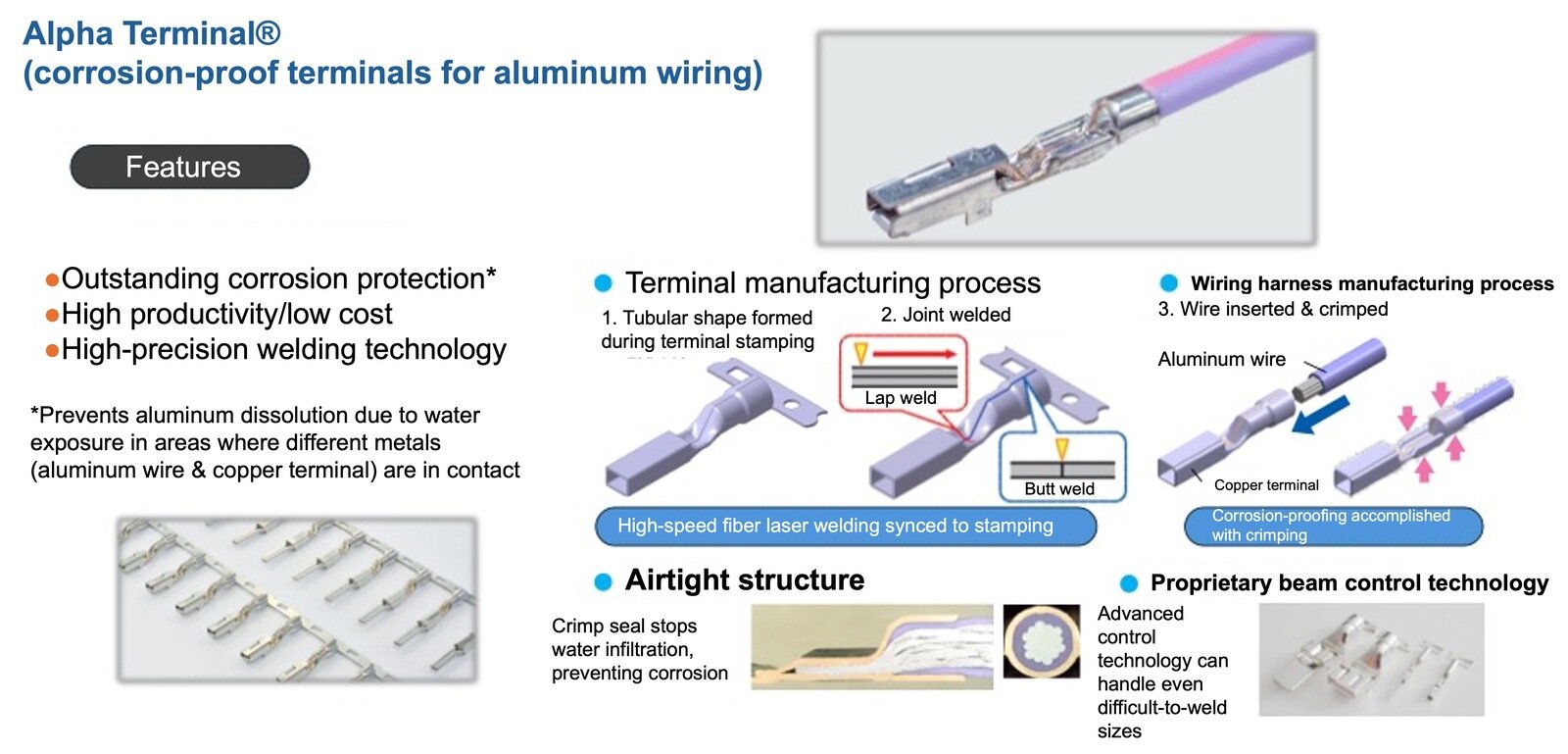

To solve this problem for the new aluminum wiring, Toyota employed Alpha Terminal®, connectors developed by Furukawa Electric using fiber laser welding to create an airtight structure.

By simply inserting the aluminum wire into a terminal and crimping it, this technology creates an airtight seal that keeps water out.

As a result, the corrosion-proofing treatments that were essential with conventional manufacturing processes, such as coating the terminal connection with resin, are no longer necessary.

Fumiya Inoue, an advisor in Furukawa Electric’s PX Division who worked on the development, notes that doing away with post-processing is a major benefit in mass production.

Advisor Inoue

The conventional method involved individually corrosion-proofing each piece, so there was no way to speed up manufacturing. Now, Alpha Terminal® has enabled high-speed, continuous production with automated machinery.

As such, this approach also ensures high productivity in mass manufacturing.

The chance to work together and hone our unreleased aluminum wiring in motorsports, and to deliver a solid performance in this demanding race environment, was an invaluable opportunity that will aid our future development.

The road ahead

At this season’s Fuji 24 Hours, the liquid hydrogen Corolla showed solid progress toward commercialization.

However, President Takahashi says, “Much remains to be done before this reaches the market.”

President Takahashi

If we consider actual use by customers, I still don’t think we have reached the point where people would be eager to trade in their current gasoline-powered vehicles for hydrogen.

That being said, this race has shown that all of the technologies we developed to facilitate commercialization are serving their intended purpose.

It is crucial that we continue to advance them further, and while various problems will no doubt crop up as we move forward, I believe that working through them one by one will lead us to a future where these cars are available as products for our customers.

The road ahead may still be long. But one thing is for certain: further down this path, an as-yet unseen world awaits.