The Takaoka Plant is home to Toyota's first dedicated BEV production line in Japan. What efforts are being made at the genba to create a working environment welcoming to all?

Doing away with physically taxing tasks

Alongside the adoption of digital tools, the Takaoka Plant is also working to introduce robots in various areas. The aim is to have robots handle physically demanding tasks, making work easier for human workers.

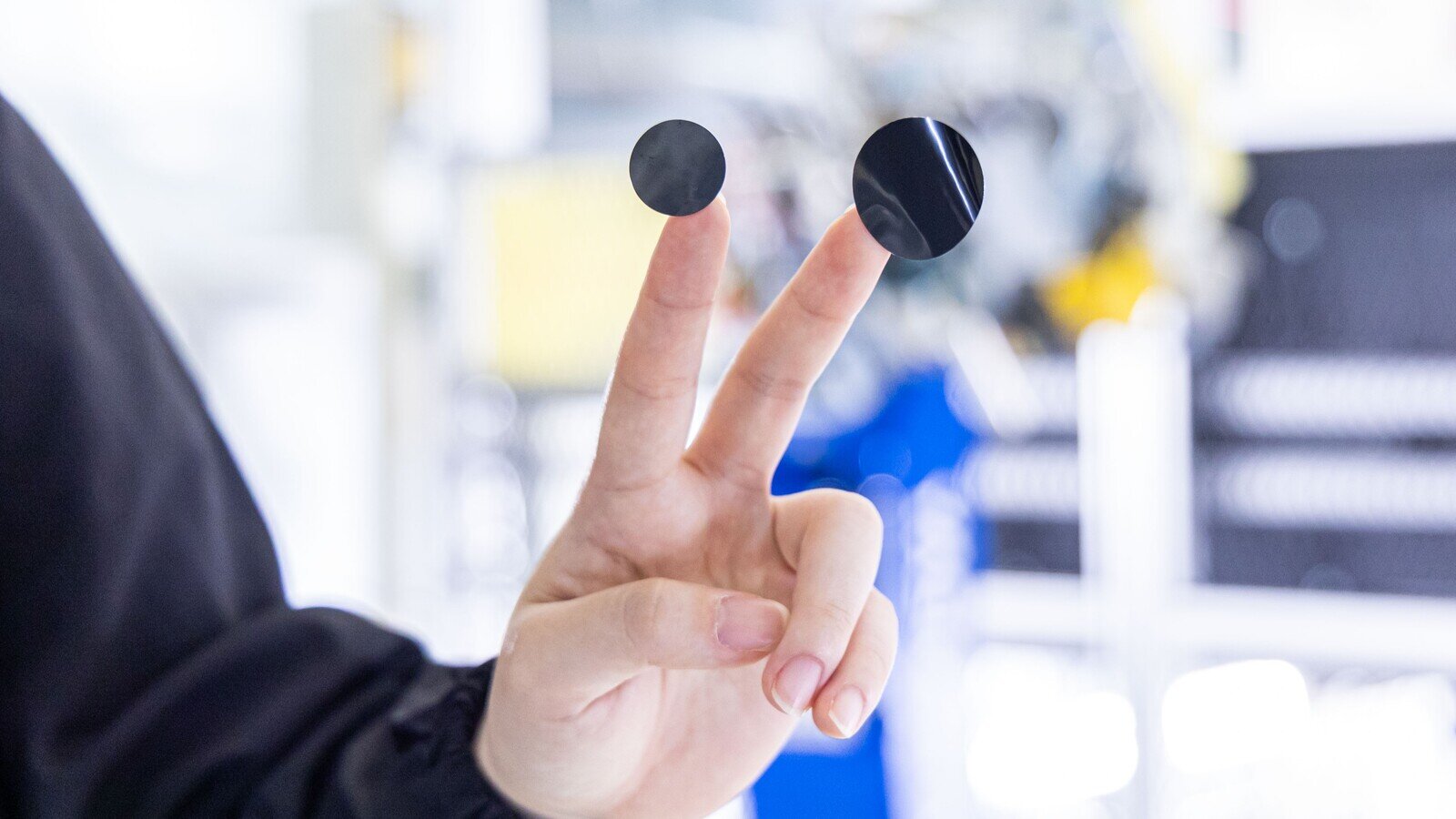

After the stamping and welding processes in body manufacturing, the body shell is sent to the paint shop still containing holes required in upstream processes. These holes are unnecessary on a finished vehicle, and if left as-is, could allow water to enter the cabin. To prevent this, they are closed off with adhesive patches.

The patches are applied by hand as the body passes overhead. A single vehicle has around 30 such holes, requiring different patches depending on their size.

The task entails looking up at the vehicle body while selecting and applying the right patches, which is both mentally and physically demanding.

Thankfully, efforts are underway to automate the task using robots, with workers moving into the role of robot operators.

One such person is Ayumi Kagiya of the plant’s Surface Finishing & Plastic Division. “I worked in this stage of production, so I want to use my experience in its evolution,” says Kagiya. “Above all, I wanted to make the job easier for our team. I also see this as an opportunity to gain new skills.”

In developing the process, Kagiya learned how to train robots—something she had no experience in—from a senior colleague, TL Yuji Yotsuda.

The vehicle inspection process is likewise being improved to ease the physical toll on workers.

As the photo below shows, to check a vehicle’s underbody and suspension, Quality Control Division staff previously had to look at the car from below with a flashlight. This not only placed considerable strain on the shoulders and neck, but also required workers to keep the inspection checklist in mind as they worked.

Now, as a vehicle moves through the assembly process, numerous cameras capture images of the underbody.

Operators check the resulting images on their monitors.

Together with the inspection checklist, these monitors show images of the current vehicle, as captured by the cameras, alongside a reference image. This not only eases the toll on operators but also helps prevent oversights and errors of judgment.

Within the division, this stage of the process has been dubbed the “Diversity Department,” since it allows people of all genders and physical abilities to perform inspections in the same way. EX Miki Otsuhata and EX Kiyosuke Kaneta, who are leading the adoption of this new approach, plan to expand it to other inspection tasks.

Changes for a stronger genba

Next, we looked at the final assembly process, where interior fittings, bumpers, doors, and other parts are mounted onto painted vehicle bodies.

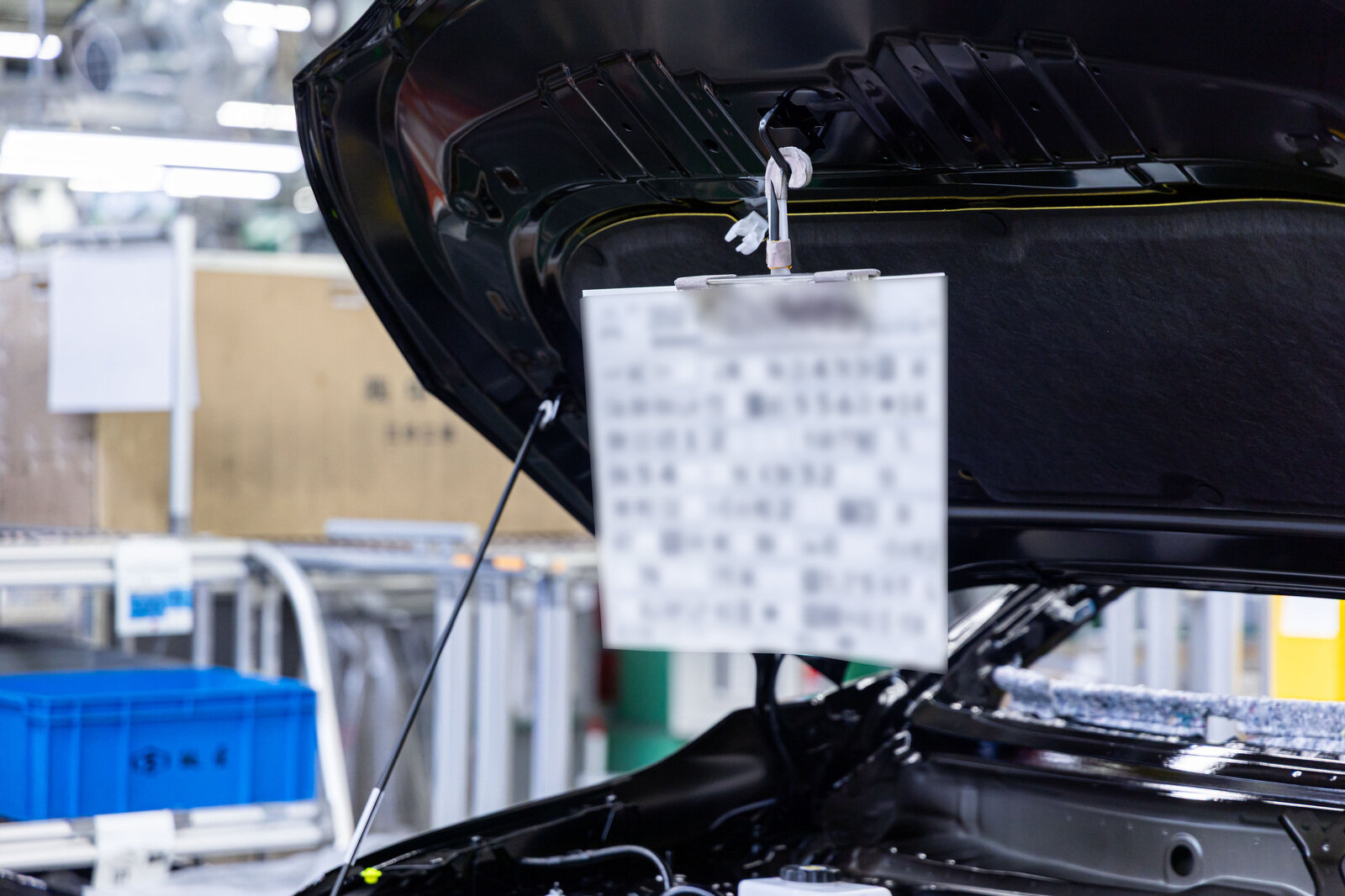

Each body that comes down the line bears a paper instruction sheet listing all of the parts to be assembled by each section.

Line workers check the necessary parts by deciphering the combinations of symbols, letters, and numbers that fill the A3-sized page.

Should they happen to misread one, the car may end up being delivered to customers with an incorrect part.

What’s more, certain parts are mounted inside the vehicle where the instruction sheet is not visible, forcing workers to go in and out every time they need to check it.

The plant is addressing these issues with electronic instruction sheets that show each assembly worker only the information they require.

These electronic sheets are displayed on tablets mounted on the work carts used for assembly. Parts requiring special attention can be highlighted, reducing the mental strain of worrying about misreading.

The Takaoka Plant has also introduced wristwatch-style devices that display assembly information, which eases the physical burden by eliminating the need to go in and out of vehicles to check instructions.

Many employees praise the watches for doing away with the wasted effort of getting in and out of vehicles and making the job easier on the body.

Final Assembly Division members EX Hisashi Yoshimura and Assistant Manager Kazuo Kawai have been driving the adoption of this electronic solution. “People on the assembly line are constantly paying close attention to avoid mistakes, relying on their memory and careful focus. Electronic instruction sheets certainly reduce that burden and make the job easier,” they told us. “Implementing these tools supports the genba’s strength in building quality into the production process. That is what I see as our role.”

Alongside these ongoing improvements to work practices on the production line, the Takaoka Plant is also making major changes to its logistics operations.