Toyota's Plants: Inheritance & Evolution is a series introducing the history and vision behind individual production facilities. This installment explores the history of the Takaoka Plant, built to produce popular cars for the mass market.

In the wake of the Second World War, from around 1955 to the early 1970s, Japan underwent a period of rapid economic growth.

By the 1960s, the aspirations of many Japanese people could be summed up by three mass-market consumer products—the “three C’s” of a color television, a cooler (air conditioner), and a car—leading to a surge in automobile sales.

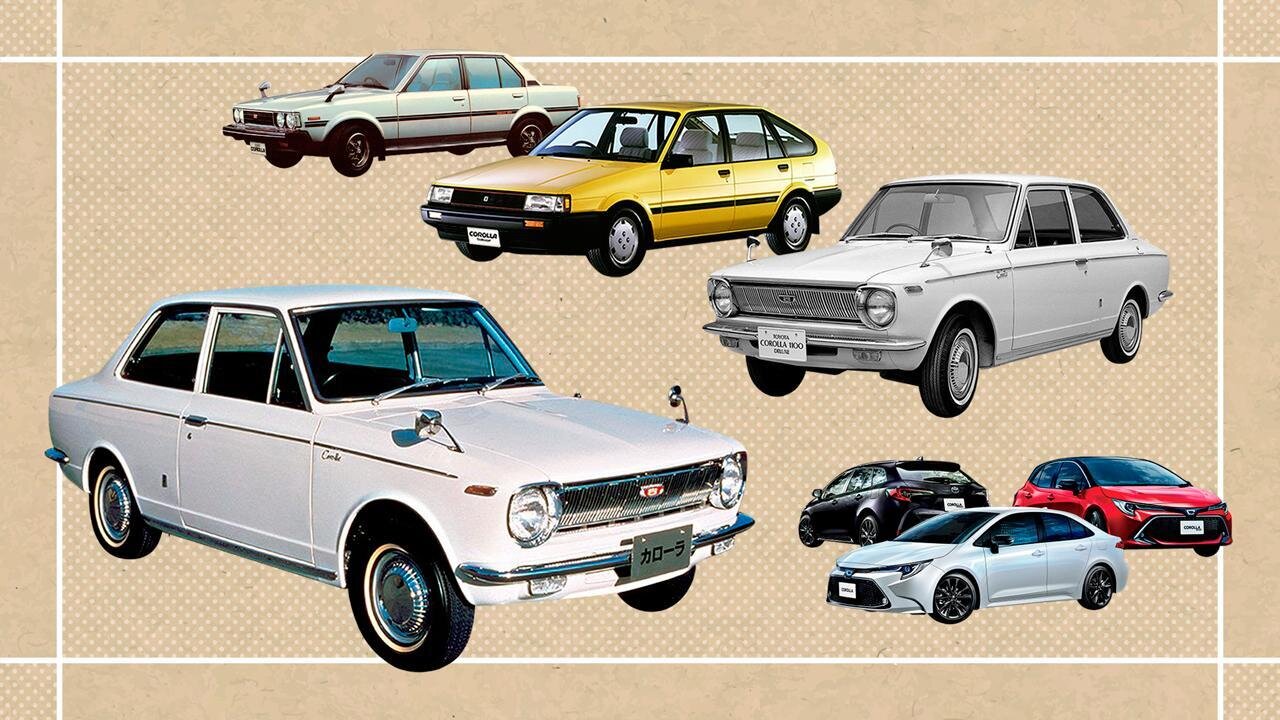

The year 1966 would later be regarded as the start of a new era of personal car ownership, spurred in part by the arrival of the first-generation Corolla.

Upon release, the model became an instant hit, leaping to the top of domestic sales. The Corolla established itself as an affordable and dependable “people’s car,” playing a key role in Japan’s motorization.

From the launch of that first generation, the Corolla continued to lead annual sales figures through numerous updates over 33 years, until 2001. Even after that point, it has remained a beloved and popular model.

In this article, we retrace the history of Toyota’s Takaoka Plant, which was originally built to produce the Corolla.

As one of the facilities that helped make cars a part of everyday life, how has the Takaoka Plant changed with the times?

An unprecedented production target

In September 1966*, Takaoka opened its doors as a dedicated Corolla plant.

*The completion ceremony was held on December 7.

Today, the site has grown into a vast production facility straddling the three cities of Toyota, Miyoshi, and Kariya in Aichi Prefecture.

When the plant was first established, Toyota set a monthly production target of 20,000 vehicles.

By contrast, the Motomachi Plant, which also specializes in passenger cars, had an initial target of 5,000 vehicles per month when it commenced operations in 1959. Takaoka marked an unprecedented challenge for Toyota.

From stamping body panels to welding, painting, and assembly, the plant adopted the latest equipment of its day. What’s more, it became Toyota’s first facility to incorporate what we would now call computer-based production management.

Within the plant, a central control room managed aspects such as parts inventory and the operating status of equipment.

From its launch, the Corolla’s sales volume continued to rise, and by 1969, the Takaoka Plant’s annual production reached 400,000 vehicles.

Eiji Toyoda, the company’s vice president at the time Takaoka was starting up, later reflected on those early days.

While some are of the opinion that the Corolla rode the wave of motorization, I think it's the other way around. We worked to create popular demand with the Corolla, and in my opinion, that's just what we did.

…

It's only because we succeeded that I can afford to say so now, but had motorization not caught on in Japan, Toyota would most likely have been strapped down with surplus facilities.

From Toyota: Fifty Years in Motion by Eiji Toyoda (Nikkei Inc.)

At first, the Takaoka Plant operated with only one line, but as demand for the Corolla soared, production was unable to keep pace. By 1970, two more lines were installed, bringing the total to three.

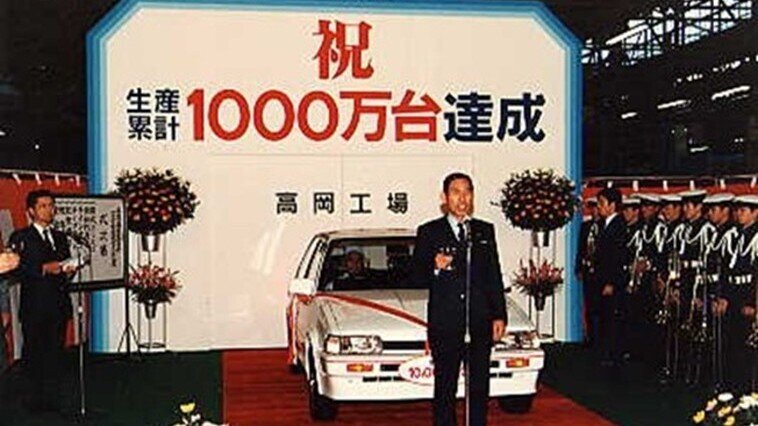

In the second half of the 1970s, Toyota’s first front-wheel drive (FF) models, the Tercel and Corsa, were added to the plant’s lineup. Annual production hit a peak of nearly 800,000 vehicles in 1980. Then in 1984, Takaoka reached the milestone of building its 10 millionth car.

Shigeki Hirose, Deputy General Manager of the plant’s Final Assembly Division, joined Toyota in 1983. He recounted the production floor atmosphere in those days.

Deputy General Manager Hirose, Final Assembly Div.

Back then, our genba had a real dynamism and drive. There was a strong sense that the Corolla was the backbone of this plant. Working with senior colleagues, we were committed to delivering great cars to our customers on time.

We always worked at full capacity, with a two-shift system running day and night. Even when your shift ended, you would stay on for two or three hours of overtime, it was just that busy. And yet, I remember us laughing together after work, saying, “That was another big day!”

Supporting Corolla production overseas

Having built up a wealth of mass-production expertise, the Takaoka Plant supported Toyota’s endeavors overseas.

In 1984, the company established New United Motor Manufacturing, Inc. (NUMMI) in the United States as a joint venture with General Motors (GM), setting up its first real mass-production facility outside Japan.

Takaoka became the mother plant tasked with supporting the launch of NUMMI. It welcomed local employees from America for training.

NUMMI went on to become Toyota’s Corolla production base in the United States.

Then in the 1990s, the Takaoka Plant also began producing a certain hybrid that left an outsized mark on global automotive history.