The Takaoka Plant is home to Toyota's first dedicated BEV production line in Japan. What efforts are being made at the genba to create a working environment welcoming to all?

Letting robots do the heavy lifting

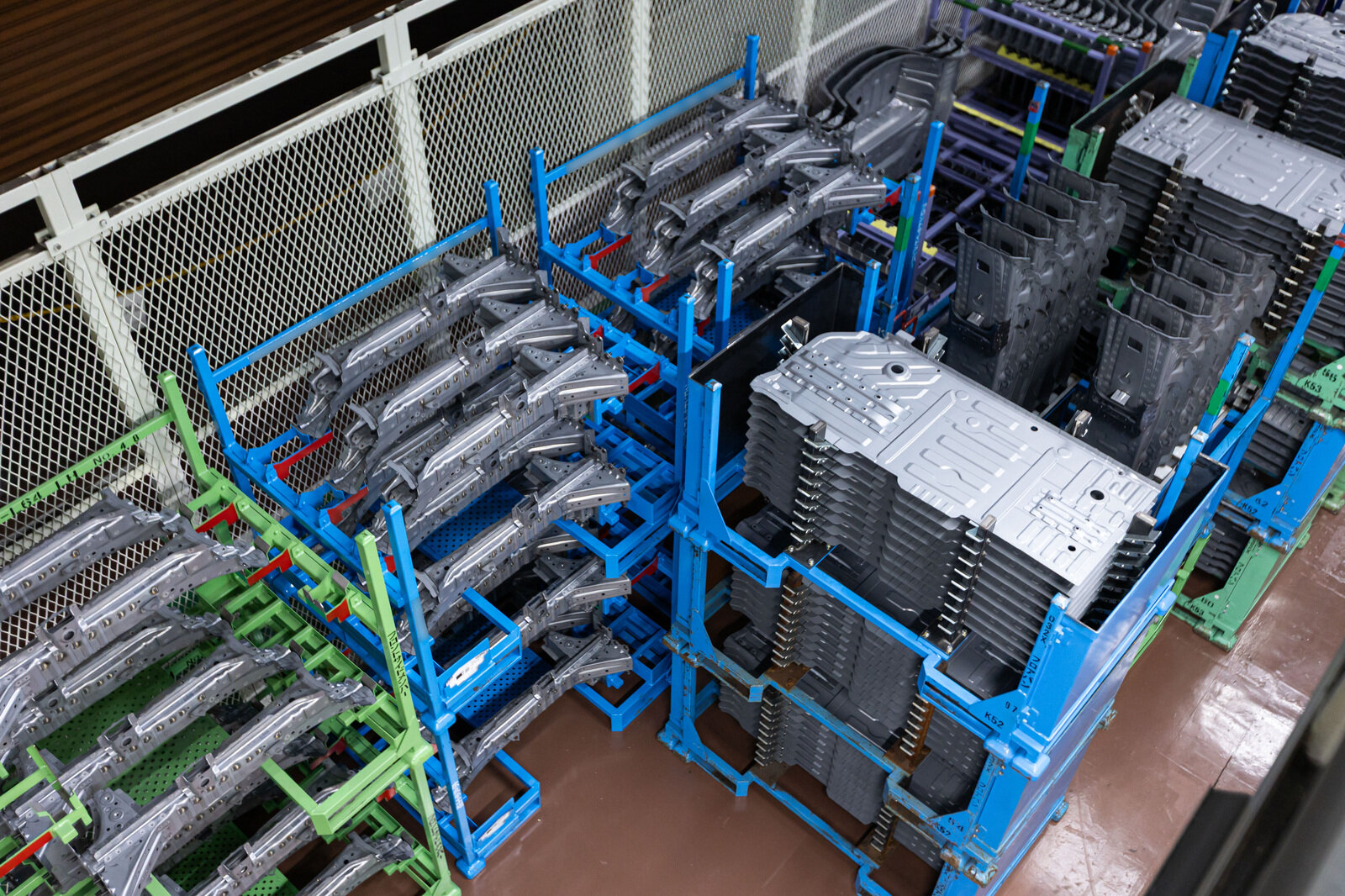

The photo above shows parts that will be welded together to create vehicle body frames. Before arriving here, these components are delivered to the plant’s yard by logistics contractors.

Since their trucks are unable to enter the plant, drivers must switch to forklifts to unload each shipment.

Once the parts are inside, the plant’s logistics personnel use transporter vehicles to deliver them to the appropriate sections. This setup requires both the truck drivers and logistics staff to travel back and forth through the vast plant.

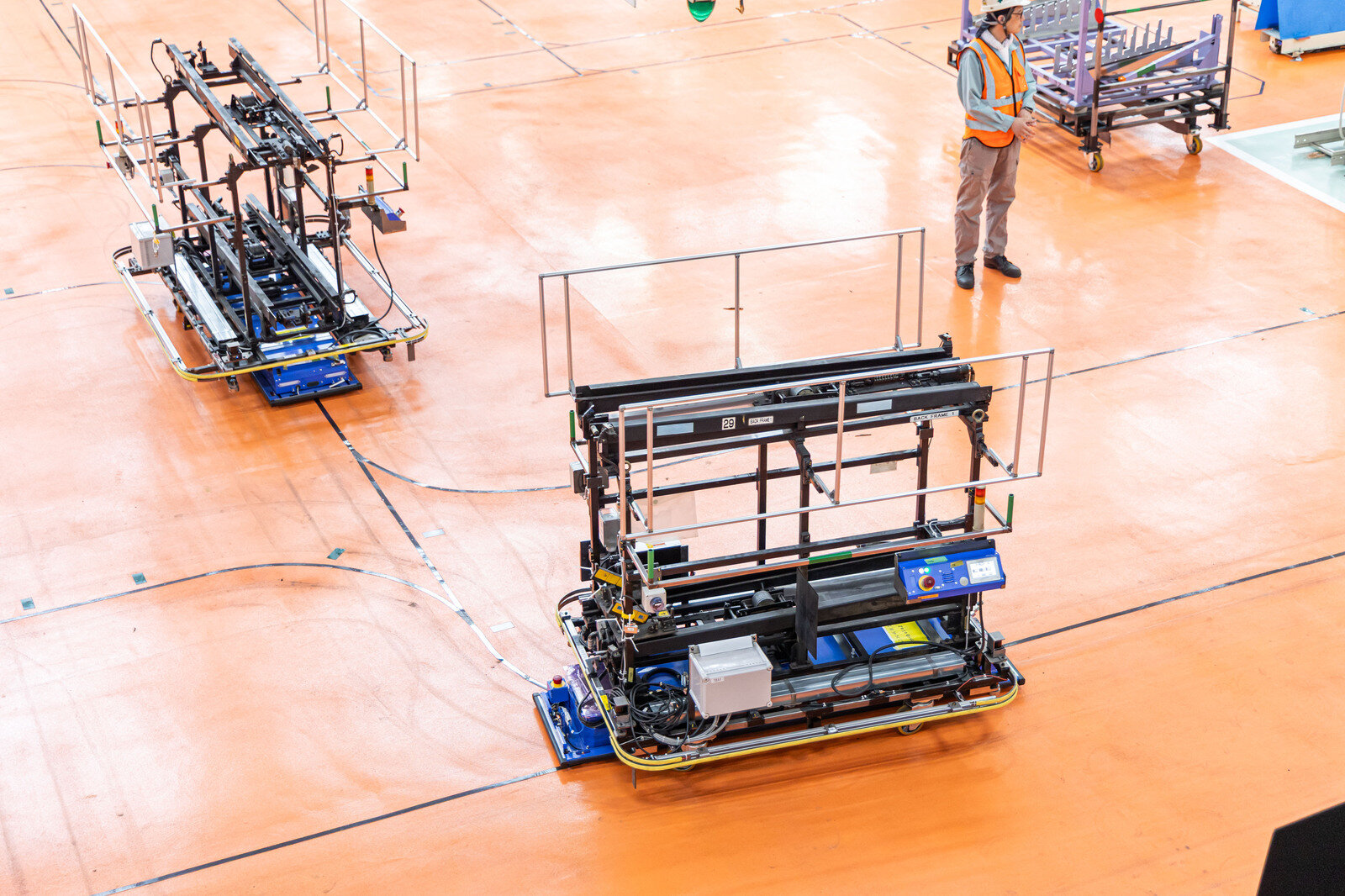

To streamline this operation, Takaoka is turning to Autonomous Mobile Robots (AMRs) for transporting parts.

AMRs can move forward, backward, left, or right, and make their way around by reading 2D codes affixed to the floor.

With such codes arranged throughout the plant, operators can map out the optimal route for a given situation.

Onboard sensors automatically ensure that the robots avoid collisions with other AMRs or obstacles.

Automated Guided Vehicles (AGVs) are another option for unmanned transport within production plants. However, because they move by following magnetic tape along the floor, routes cannot be easily altered once set. Among other disadvantages, AGVs are unable to navigate around obstacles in their path.

By contrast, the flexible route-setting of AMRs makes it possible to cover a larger area with unmanned transport. Combined with reorganizing the logistics yard, this upgrade means that delivery drivers now travel no more than five meters from their truck when unloading by forklift.

The fact that truck drivers no longer need to bring shipments into the plant also reduces the risk of accidents.

AMRs autonomously convey parts within the plant as well, reducing the distances driven by transporter operators.

“Whereas AGVs function like rail cars running on tracks, AMRs are more like robot vacuums,” explains Hiroki Aonuma of the logistics improvement team.

Emphasizing the potential of AMRs to “completely” eliminate the physically demanding tasks in logistics, Aonuma noted that these reforms also provide an opportunity to develop the plant’s personnel.

Aonuma, Quality & Logistics Section, Body Manufacturing Div.

In logistics, digital systems are major sources of competitive advantage. By having AMRs take over the task of transporting goods, you also relieve the burden on drivers.

To make that happen, those of us working in logistics must be able to handle everything else, including robot maintenance, and learn how to incorporate digital solutions into TPS. The Takaoka Plant is nurturing logistics maintenance personnel with these kinds of skills.

Aonuma himself is a case in point, having started the AMR project with zero knowledge of aspects such as control programming or data management. He says that, initially, even getting one unit going was a struggle.

Through the trial-and-error process of implementing digital solutions in the genba, he gradually built up his knowledge of logistics maintenance. Today, he oversees a fleet of 160 AMRs.

Kyoka Yono is currently on transfer from Takaoka to gain expertise at the Motomachi Plant’s Logistics & Information Manufacturing Engineering Division. She wants to use this knowledge to help create workplaces where everyone can thrive.

Yono, Logistics & Information Manufacturing Engineering Div., Motomachi Plant

In areas that involve carrying or setting parts in machinery, many of the roles cannot be performed by women due to load restrictions.

By having robots handle tasks with such restrictions, we can shift people to roles where everyone can make equal contributions. This is both a vision for the plant as a whole and what we should be working towards.

Making parts logistics more worker-friendly

The innovations in logistics also extend to sorting and transporting smaller parts.

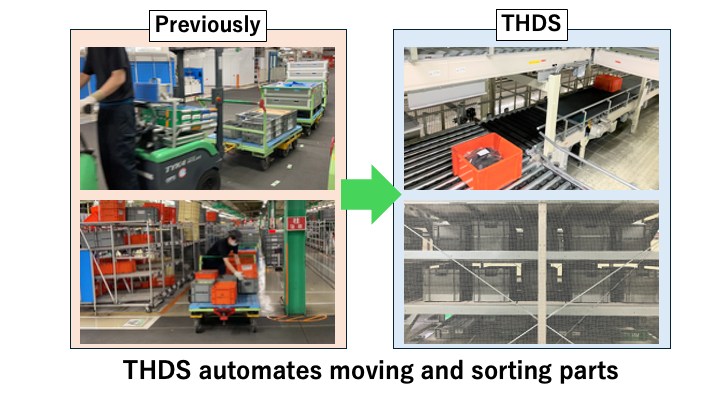

This photo shows the Toyota High Density Storage Sorting System—or THDS—developed on the assembly lines at the Takaoka Plant.

A single car is said to contain some 30,000 parts. As the name suggests, THDS is a system that deals with all the parts delivered by logistics contractors, automatically sorting them according to type and the production stage in which they are required.

The system automates the task of moving and sorting parts onto their designated racks, previously carried out by the plant’s logistics personnel using transporters.

Parts for specific production stages can then be entered into THDS as required, and the system will automatically prepare them for pickup.

Previously, line workers had to search for and retrieve what they needed from the racks of components. In a single day, they would walk as much as 15 kilometers. Thanks to THDS, that figure has fallen to around 2.7 kilometers. Pick-up points are also set at heights that can be easily reached by all staff.

Sayu Isogai, Final Assembly Div.

In the past, when we would walk around retrieving parts, I often had to stand on tiptoe to get them.

With THDS, we no longer have to search around for parts, and the crates are set up within easy reach, which is incredibly helpful.

When Takaoka embarked on the THDS project, genba staff ranging from the assembly line to equipment maintenance volunteered their specialized knowledge, bringing this expertise together in a tight-knit team.

“We want to ensure that aspects like age or physical differences don’t stop anyone from thriving in the workplace,” says Assembly Maintenance Section Team Leader Masaki Shibuya. “The THDS initiative aligns with our company-wide mission, so it would be wonderful to see this spread to other plants.”

Leveraging the latest technologies, the Takaoka Plant is undergoing a transformation that will improve working conditions for all.

At the same time, however, these advances in digitalization and robotics raise a troubling question: will human workers cease to be necessary?

When we posed this question at the next genba, their answer was clear. “The need for human skills will never disappear.”