Toyota's Plants: Inheritance & Evolution is a series introducing the history and vision behind individual production facilities. This installment explores the history of the Takaoka Plant, built to produce popular cars for the mass market.

Back to single-line production

In 2009, in the wake of the financial crisis that occurred the previous year, Toyota’s operations fell into the red for the first time since the company’s founding.

Sales of core models such as the Corolla and Vitz plunged, leaving the Takaoka Plant with no cars for its upgraded facilities to produce.

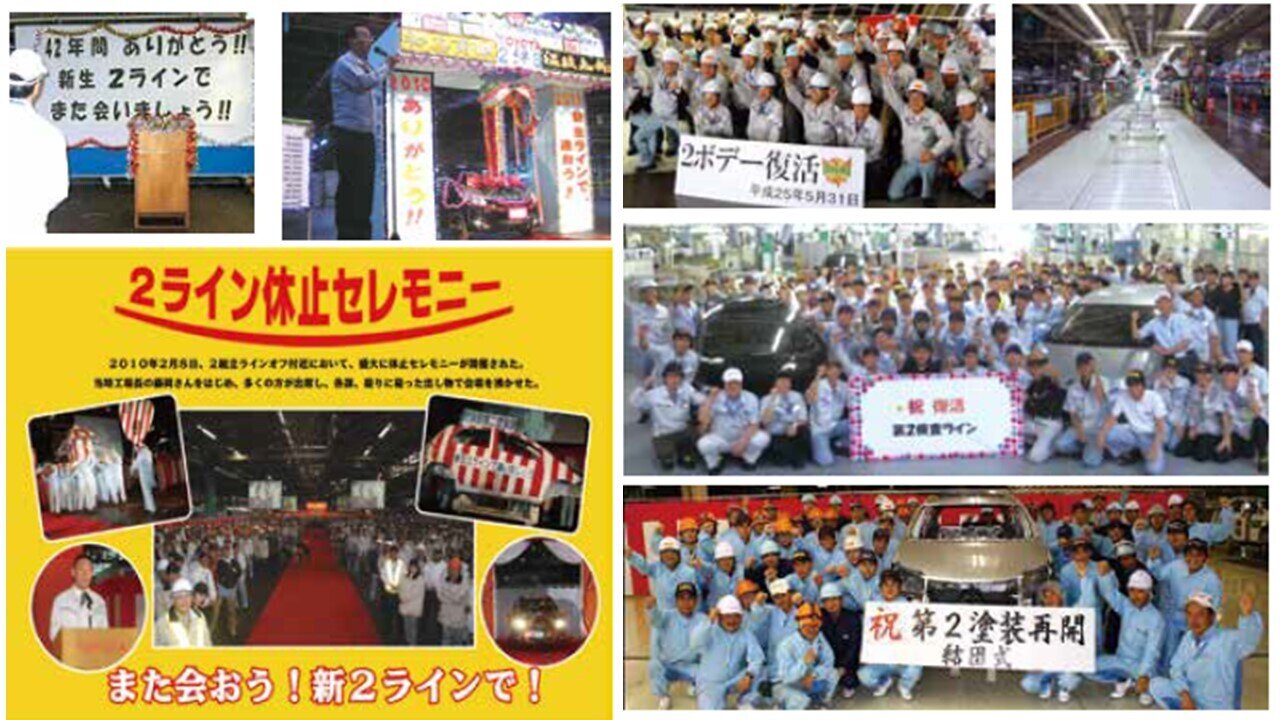

In the end, the existing two-line system became unsustainable, and Line 2 halted production the following year, in 2010. From there, annual output fell below 200,000 vehicles, a record low in the plant’s history.

The Surface Finishing & Plastic Division’s Deputy General Manager Kawana recalled the air of uncertainty that pervaded the genba following the plant’s decision to suspend Line 2.

Deputy General Manager Kawana, Surface Finishing & Plastic Div.

The toughest part about shutting down the second line was seeing team members we had worked with get transferred to other plants.

We had to discuss how many people to transfer from each section, and who would be moving to other plants. Even though you know there is no way around it, parting with the colleagues who had worked alongside you was really painful.

However, the Line 2 suspension only served to bring Takaoka’s genba personnel closer together.

Genba effort revives Line 2

Deputy General Manager Nakayama, Body Manufacturing Div.

I still remember how heartbreaking it was when production slowed, and the machinery fell silent. Despite that, all of us in the genba firmly believed that Line 2 would be restored.

That’s why, with our remaining line, we were determined to keep striving for quality and constant improvement and continuing to make great cars. If we kept on producing consistently, the cars that mattered most to Toyota would be entrusted to us at Takaoka. This spirit of optimism filled the plant.

Then in 2013, the genba’s efforts were rewarded.

With the Takaoka Plant chosen to produce the newly released third-generation Harrier and fourth-generation RAV4, in June 2013 Line 2 restarted operations.

Annual production rebounded to nearly 400,000 vehicles, and both models gained popularity that continues to sustain the Takaoka Plant today.

“If we had fallen to doing a mediocre job during that time, Takaoka probably wouldn’t be what it is today,” notes Deputy General Manager Nakayama. “I believe that our collective effort to energize the plant is what led to the restoration of Line 2.”

Deputy General Manager Hirose of the Final Assembly Division also credits the unique strengths of the Takaoka Plant genba with reviving the second production line.

Deputy General Manager Hirose, Final Assembly Div.

We work as one, creating energy and immediately channeling it into action. I think that’s the essence of Takaoka.

Visitors to the plant often comment that Takaoka is brimming with life.

Looking back at what led to the restoration of Line 2, this dynamism comes to the fore.

We had all worked at Takaoka as it built the Corolla, Prius, and other cars that were central to Toyota. Driven by this sense of pride, we all fought hard to restore Takaoka’s monozukuri.

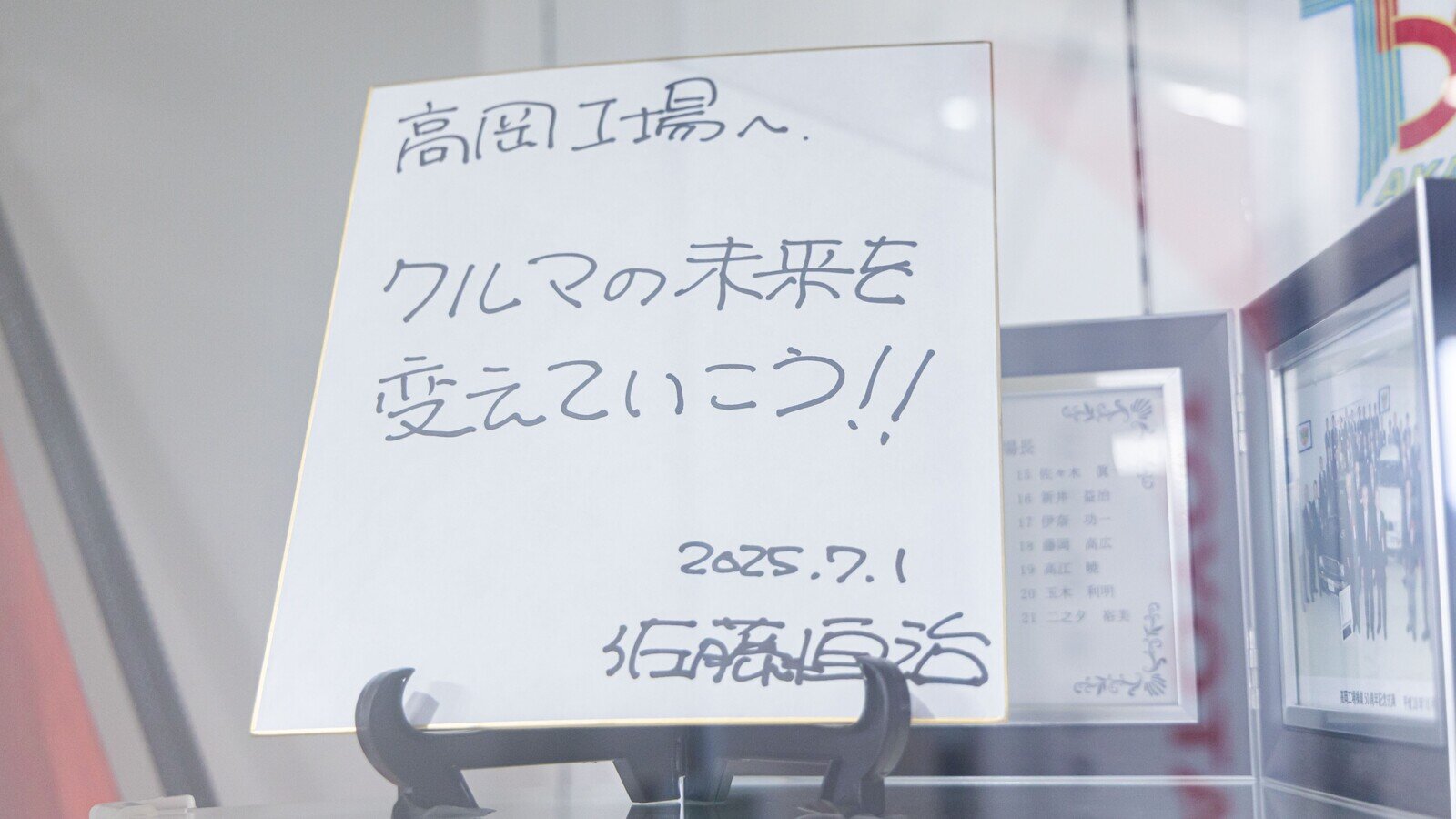

One of those “visitors to the plant” was none other than President Koji Sato. In fact, he toured the facility just a few days before we spoke with the team in July.

As he made the rounds and chatted with employees in each section, President Sato is said to have remarked, “What a vibrant plant.” It seems Takaoka’s unique character remains as strong as ever.

A plant that runs on the energy of its people

Team unity and dedication. These strengths of the Takaoka Plant are also visible outside of work.

The annual winter relay race, HURE! Hure! Ekiden, is a Toyota tradition dating back to 1947. For the past four events, from 2019 to 2024, Takaoka’s Final Assembly Division has triumphed in the premier Long category, cementing its position as undisputed champions.

*The 2020 and 2021 races were canceled due to the COVID-19 pandemic.

Senior Expert Nobuo Nakatsuyu, who serves as the Final Assembly Division’s head coach, revealed the secret to the team’s strength:

“Running for someone other than yourself, working together to get that sash to the finish line—it’s just like the carmaking genba. To create a single great vehicle, each person must give their all in their assigned role, while working closely as a team. I believe this dedication and spirit of unity that is deeply ingrained at Takaoka has also helped us to keep winning in the ekiden.”

As we mentioned earlier, the Takaoka Plant straddles the three Aichi Prefecture cities of Toyota, Miyoshi, and Kariya. Partly in gratitude for being given access to this vast site, the plant personnel view contributing to the local community as part of their mission.

The majority of participants in these community initiatives are members of the Sansokai, comprising staff at the managerial level in skilled technical roles (CX, SX, EX, etc.).

When asked about these efforts, Sansokai member EX Shingo Okamoto responded, “As well as being part of the company, we are first and foremost part of society and must never forget our ties to the community. These initiatives serve as a reminder and an opportunity to improve our people skills.”

The history and traditions of Takaoka have been forged through the dedication of the genba. When we spoke with Plant General Manager Mitsuhiro Morita, he emphasized that the energy of those who work there will also shape the plant’s future.

Plant General Manager Morita

I think the shutdown and restoration of the second production line was a major catalyst that solidified the unique character of the Takaoka Plant.

Even with just a single line, we were determined to protect and bolster Takaoka and ensure that the plant was once again recognized throughout the company. To make that happen, we needed to grow by drawing on our dynamism and people skills.

It is because those working on our front lines knew what was at stake and acted accordingly, that Takaoka exists as it does today.

One of the strengths of Toyota employees is that, when entrusted with a job, they take the initiative to go above and beyond, and for this I feel very fortunate.

Because of that, my mission as the plant’s general manager is to create an environment where our genba personnel can flourish.

Everyone contributing and helping to maintain our production volume, to ensure that Takaoka remains the wonderful place that it is—I think that’s the way this plant is meant to operate.

From the Corolla to the Prius and various compact cars, the Takaoka Plant has continued to build many beloved popular models.

Starting this August, the Takaoka team has also embarked on a new challenge: Line 1, the renowned “Innovation Line,” is being converted into Toyota's first dedicated battery electric vehicle (BEV) production line in Japan.

The plant that helped bring cars to the masses will now strive to do the same with BEVs. As part of these efforts, to borrow the words of Plant General Manager Morita, each section is striving to “create an environment where genba personnel can flourish.”

For more details, make sure to read the second part of this article, delving into the Takaoka Plant’s continuing evolution.