Toyota's Plants: Inheritance & Evolution is a series introducing the history and vision behind individual production facilities. This installment explores the history of the Takaoka Plant, built to produce popular cars for the mass market.

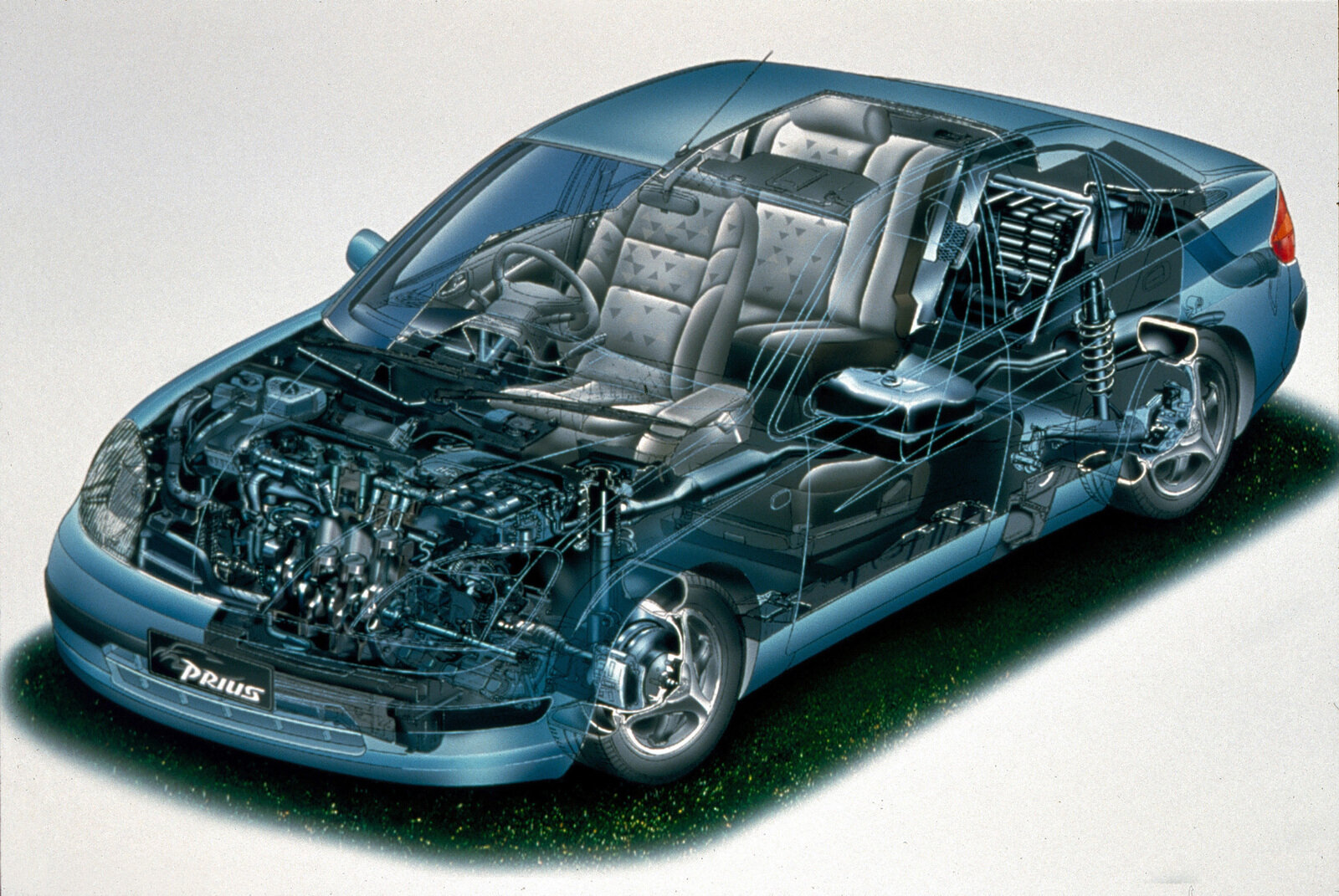

Building Toyota’s future: the first-generation Prius

In December 1997, the Takaoka Plant found itself at a pivotal moment in history. That month, the world's first mass-produced hybrid vehicle, the Prius, went into production.

Takaoka’s selection for the first-generation Prius stems from the fact that it was already producing three popular models, the Corolla II, Tercel, and Corsa.

The thinking was that, even if the Prius failed to sell as expected and fell short of production plans, as a whole the plant would still be able to maintain a high utilization rate.

Structurally, the need to mount a hybrid system within the vehicle required specialized equipment and operations at every step of the process, from stamping and welding to painting and assembly.

This led to the creation of a temporary low-volume line—the “Prius line,” as it were.

At the time, Surface Finishing & Plastic Division Deputy General Manager Yuji Kawana’s role was to program painting robots for the Prius. He emphasized how ambitious this model truly was.

Deputy General Manager Kawana, Surface Finishing & Plastic Div.

Actually, the first-generation Prius was also a major challenge in terms of design.

Among the body color variations was a sky blue tone which, until that point, had never been used on any car.

Producing that texture and color was really difficult, including the robot operations. I remember the trial-and-error process of painting actual cars, then going back and forth with the designers until we had it right.

Despite the challenges, the first Prius rolled off the production line in December 1997.

Watching the finished vehicles as they left the plant, Deputy General Manager Kawana remembers feeling a special joy at being part of the team that brought this car into the world.

By 2000, production of the original Prius was relocated to Toyota’s Motomachi Plant, as Takaoka embarked on a new challenge.

Line innovation improves quality, competitiveness, and the environment

In the 2000s, the Takaoka Plant’s lineup grew more diverse.

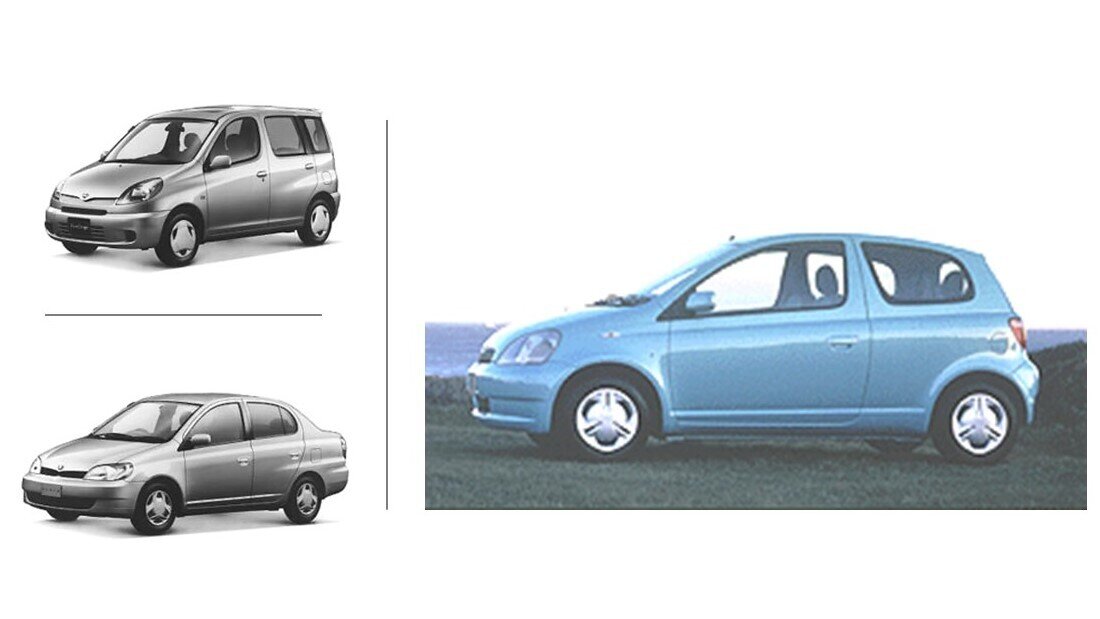

Production of the Tercel, the plant’s second most important model after the Corolla, wrapped up in 1999. That same year, Takaoka began taking on a new generation of compact cars led by the Vitz, Platz, and Fun Cargo.

In 2006, the plant used this opportunity to try something new: the first of its three lines would be revamped, with the aim of achieving world-leading quality and competitiveness in compact car production, as well as reducing environmental impact.

Intended to bring together innovative production technologies, the overhaul introduced the latest robots and technologies into every stage, while also making the line shorter.

The new Line 1 was completed in August 2007. This shortened line not only improved lead times but also cut CO2 emissions across all processes. In painting, for example, the revamp reduced emissions by 15%.

This “Innovation Line,” as it came to be known both at the plant and throughout Toyota, became a model for cutting-edge production technology.

While constructing the Innovation Line, the Takaoka team also worked to merge its other two production lines as part of a company-wide plant reorganization. In October 2007, Line 3 was shut down, and the Takaoka Plant moved to a two-line configuration.

During the launch of the Innovation Line, Hitoshi Nakayama (Deputy General Manager, Body Manufacturing Div.) oversaw the integration of new equipment and the setup of operations for the stamping process. He described the effort involved.

Deputy General Manager Nakayama, Body Manufacturing Div.

When you introduce new equipment, you also need to update the chain of command and coordination of personnel on the ground. We literally revised our operations from square one, and the revamp roughly doubled the speed of production.

However, increasing speed means nothing if it results in more defects. There were many problems when the Innovation Line first started up, but we continued to make improvements, ensuring that we built quality into the process.

With the Innovation Line up and running, the Takaoka Plant was ready to take production to another level.

Unfortunately, the road ahead was about to get rough.